-

What happened?

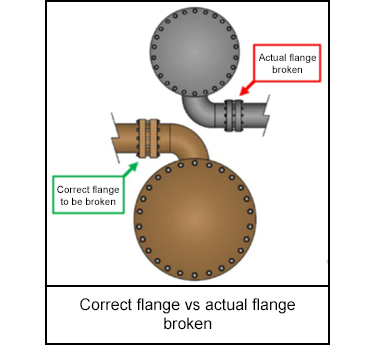

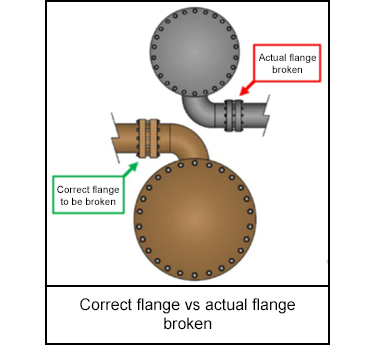

A maintenance worker was instructed to reduce bolt a flange join on a heat exchanger shell. This was in the work scope and documented in the work permit.

The worker set up their work area and then commenced work on the wrong heat exchanger shell, which was live.

An operator noticed that work was proceeding on the wrong exchanger shell and instructed the worker to stop.

-

Why did it happen?

The worker was unsure about the job scope but did not stop to confirm they were working on the correct flange.

-

What did they learn?

Prior to commencing work read your work permit.

Confirm that the work permit matches the equipment you will be working on.

Confirm you have the correct authorisation before commencing work on equipment.

Ensure equipment is isolated and safe to work on before commencing work.

If you are unsure of your work scope, use your stop work authority.

-

Ask yourself or your crew

If you are unsure of your work scope, do you pause and ask questions to confirm your understanding before commencing the work?

Do you always obtain the required authorisations before commencing work?

When issued with a permit to work, do you always read the permit requirements to confirm your understanding?

When working with pressurised equipment, do you always “walk the line” to ensure isolations are in place and verified? Do you check for residual pressure before breaking containment?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A maintenance worker was instructed to reduce bolt a flange join on a heat exchanger shell. This was in the work scope and documented in the work permit.

The worker set up their work area and then commenced work on the wrong heat exchanger shell, which was live.

An operator noticed that work was proceeding on the wrong exchanger shell and instructed the worker to stop.

Why did it happen?

The worker was unsure about the job scope but did not stop to confirm they were working on the correct flange.

What did they learn?

Prior to commencing work read your work permit.

Confirm that the work permit matches the equipment you will be working on.

Confirm you have the correct authorisation before commencing work on equipment.

Ensure equipment is isolated and safe to work on before commencing work.

If you are unsure of your work scope, use your stop work authority.

Ask yourself or your crew

If you are unsure of your work scope, do you pause and ask questions to confirm your understanding before commencing the work?

Do you always obtain the required authorisations before commencing work?

When issued with a permit to work, do you always read the permit requirements to confirm your understanding?

When working with pressurised equipment, do you always “walk the line” to ensure isolations are in place and verified? Do you check for residual pressure before breaking containment?

A maintenance worker mistakenly began work on a live heat exchanger shell instead of the intended one, but an operator noticed the error and instructed them to stop.

Original material courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/maintaining-process-equipment-loss-of-containment