-

What happened?

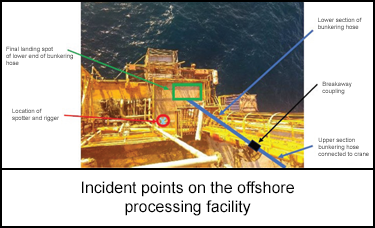

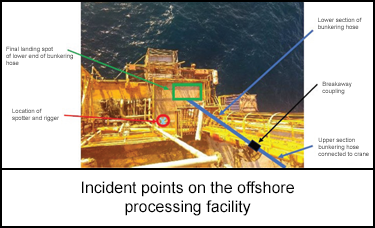

A 60 metre (197 feet), 3 inch (7.6 cm) diameter bunkering hose was being uncoiled by lifting one end with a crane at an offshore processing facility.

During this activity, the hose parted at the breakaway coupling in the middle of the hose.

The upper half remained attached to the crane whip (auxiliary) line via the hose lifting saddle and 1 tonne (2205 lbs) soft sling.

The lower half fell back down to the landing area. The dogman and spotter were standing to one side.

After hearing a pop and seeing the hose end closest to the deck falling, they exited the lower landing area.

There were no injuries associated with this event. The weight of dropped section was estimated to be 150 kg - 200 kg (331 lbs – 441 lbs).

The drop height of the lower end was approximately 10 metres (33 feet). This could have been fatal (Dropped objects prevention scheme [DROPS] calculator).

-

Why did it happen?

During bunkering hose re-certification, a damaged coupling was changed out. The management of change process was not followed. The replacement was not like-for-like.

Marine breakaway couplings are designed to only release by inline pull and are to be used between two strings of hose.

The replacement was an industrial coupling, typically installed where at least one side of the coupling is attached to a fixed point. Angular tensile forces will activate the breakaway.

It’s believed when lifting the hose string, the industrial coupling contacted a fixed point causing angular tension, releasing the coupling.

-

What did they learn?

Reinforce requirements of management of change processes.

The lifting procedure stated that standing below loads is to be ‘minimised’. This is inconsistent with industry best practice.

Standing below a load should never be accepted. Procedures and controls should be revised to stipulate that ‘no work activity shall be allowed under a suspended load’.

-

Ask yourself or your crew

Do hose lifting operations occur at your worksite? Does this activity have safe lifting procedures? Do you follow them?

Do you follow management of change processes when changing hose configurations, connections or service?

Do you always avoid standing under a suspended load?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A 60 metre (197 feet), 3 inch (7.6 cm) diameter bunkering hose was being uncoiled by lifting one end with a crane at an offshore processing facility.

During this activity, the hose parted at the breakaway coupling in the middle of the hose.

The upper half remained attached to the crane whip (auxiliary) line via the hose lifting saddle and 1 tonne (2205 lbs) soft sling.

The lower half fell back down to the landing area. The dogman and spotter were standing to one side.

After hearing a pop and seeing the hose end closest to the deck falling, they exited the lower landing area.

There were no injuries associated with this event. The weight of dropped section was estimated to be 150 kg - 200 kg (331 lbs – 441 lbs).

The drop height of the lower end was approximately 10 metres (33 feet). This could have been fatal (Dropped objects prevention scheme [DROPS] calculator).

Why did it happen?

During bunkering hose re-certification, a damaged coupling was changed out. The management of change process was not followed. The replacement was not like-for-like.

Marine breakaway couplings are designed to only release by inline pull and are to be used between two strings of hose.

The replacement was an industrial coupling, typically installed where at least one side of the coupling is attached to a fixed point. Angular tensile forces will activate the breakaway.

It’s believed when lifting the hose string, the industrial coupling contacted a fixed point causing angular tension, releasing the coupling.

What did they learn?

Reinforce requirements of management of change processes.

The lifting procedure stated that standing below loads is to be ‘minimised’. This is inconsistent with industry best practice.

Standing below a load should never be accepted. Procedures and controls should be revised to stipulate that ‘no work activity shall be allowed under a suspended load’.

Ask yourself or your crew

Do hose lifting operations occur at your worksite? Does this activity have safe lifting procedures? Do you follow them?

Do you follow management of change processes when changing hose configurations, connections or service?

Do you always avoid standing under a suspended load?

While uncoiling a 60 metre (197 feet) bunkering hose at an offshore facility, the hose parted at the breakaway coupling, causing the lower half (weighing 150-200 kg or 331–441 lbs) to fall approximately 10 metres (33 feet) to the landing area. Fortunately, there were no injuries.

Original material courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/lifting-person-in-line-of-fire