-

What happened?

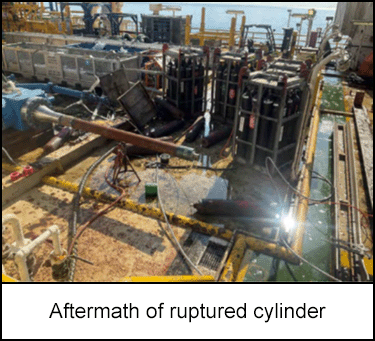

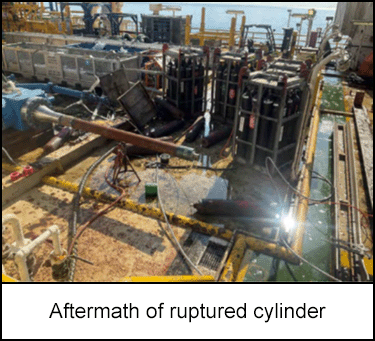

A DOT3AA high pressure nitrogen cylinder in a quad of 12 cylinders ruptured without warning.

The cylinders were charged to 2,400 psi (16.55 MPa) and were not connected to anything else at the time of the incident.

The rack was destroyed and the other cylinders in the quad were propelled by the blast.

-

Why did it happen?

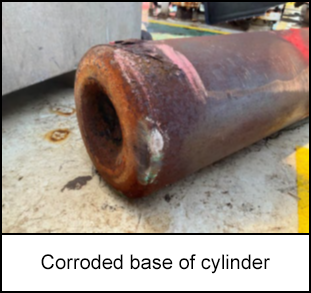

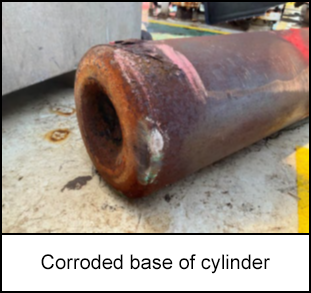

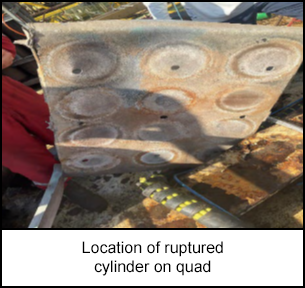

The base of the cylinder that ruptured was heavily corroded. Other cylinders in the quad had evidence of similar but less severe corrosion.

The American Society of Mechanical Engineers (ASME) fatal blast zone for a single cylinder of this size pressurised to 2,400 psi (16.55 MPa) is calculated to be approximately 1.5 metres (4.9 feet).

The cylinders were 9 years into their 10-year hydrotest cycle and had been visually inspected by the supplier in accordance with Compressed Gas Association guidance for re-filling three months before the incident, prior to being loaded out to the rig. However, the severe corrosion that caused the rupture was not spotted during this inspection.

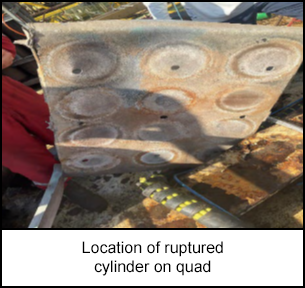

The cylinder that ruptured was located in the middle of the quad and therefore not easy to properly inspect without disassembly of the quad.

-

What did they learn?

Conduct thorough, routine inspections of cylinders in accordance with relevant standards.

Ensure that all cylinders are accessible for proper inspections. Beware of hidden corrosion and other issues that you cannot see. Consider how the method of storage of cylinders can lead to corrosion and how this can be prevented (e.g. by ensuring the rack is free-draining).

-

Ask yourself or your crew

How do you ensure that the cylinders on your facility are certified and in good condition? What methods do you use to monitor the condition of all cylinders in every rack?

How are the cylinders positioned to minimise corrosion, and are they on a free draining base?

What level of visual inspection of cylinders/quads does your supplier provide?

How are the cylinders on your facility stored and located to comply with relevant industry regulations?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A DOT3AA high pressure nitrogen cylinder in a quad of 12 cylinders ruptured without warning.

The cylinders were charged to 2,400 psi (16.55 MPa) and were not connected to anything else at the time of the incident.

The rack was destroyed and the other cylinders in the quad were propelled by the blast.

Why did it happen?

The base of the cylinder that ruptured was heavily corroded. Other cylinders in the quad had evidence of similar but less severe corrosion.

The American Society of Mechanical Engineers (ASME) fatal blast zone for a single cylinder of this size pressurised to 2,400 psi (16.55 MPa) is calculated to be approximately 1.5 metres (4.9 feet).

The cylinders were 9 years into their 10-year hydrotest cycle and had been visually inspected by the supplier in accordance with Compressed Gas Association guidance for re-filling three months before the incident, prior to being loaded out to the rig. However, the severe corrosion that caused the rupture was not spotted during this inspection.

The cylinder that ruptured was located in the middle of the quad and therefore not easy to properly inspect without disassembly of the quad.

What did they learn?

Conduct thorough, routine inspections of cylinders in accordance with relevant standards.

Ensure that all cylinders are accessible for proper inspections. Beware of hidden corrosion and other issues that you cannot see. Consider how the method of storage of cylinders can lead to corrosion and how this can be prevented (e.g. by ensuring the rack is free-draining).

Ask yourself or your crew

How do you ensure that the cylinders on your facility are certified and in good condition? What methods do you use to monitor the condition of all cylinders in every rack?

How are the cylinders positioned to minimise corrosion, and are they on a free draining base?

What level of visual inspection of cylinders/quads does your supplier provide?

How are the cylinders on your facility stored and located to comply with relevant industry regulations?

A high-pressure nitrogen cylinder in a quad of 12 ruptured, causing a blast that destroyed the rack and propelled other cylinders. The rupture was due to severe corrosion at the base of the cylinder, which was not detected during visual inspections.