-

What happened?

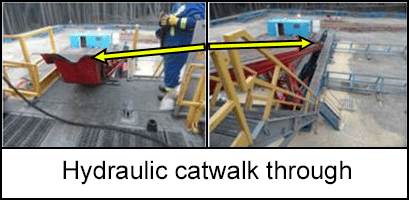

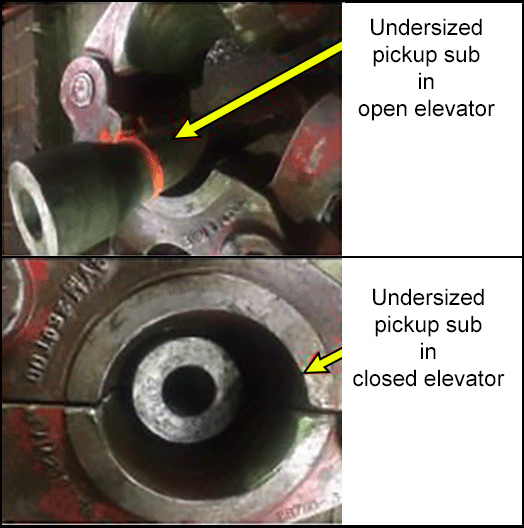

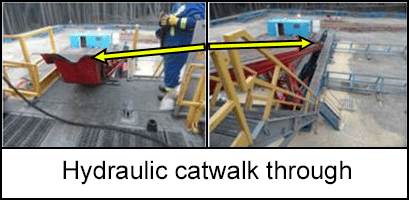

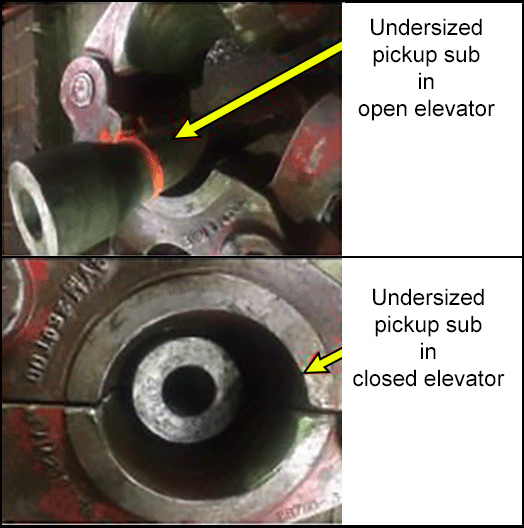

On a drilling rig, a non-magnetic drill collar (NMDC) was lifted from the hydraulic catwalk with a third party pickup sub. A pickup sub is a tool that connects to other equipment and is held in the rig elevators. Normally, the top portion of the pickup sub is larger than the inside diameter of the rig elevators to prevent the pickup sub from sliding through the elevators.

The elevators and pickup sub were 6-7 meters above the rig floor at approximately a 70 degree angle when the pickup sub slipped through the elevators.

The non-magnetic drill collar slid and bounced out of the trough and landed halfway down the catwalk.

There were no injuries.

-

Why did it happen?

The pickup sub was undersized for the rig elevators.

Contributing factors:

- Insufficient planning and communication between the directional driller, drilling company and wellsite supervisor.

- No one had measured the outside diameter of the pickup sub to ensure it was compatible with the inside diameter of the rig elevators.

- The hazard assessment and pre-job checklists did not include pickup sub compatibility.

-

What did they learn?

- Drilling rig, directional drillers, service providers and producers need to work collaboratively to ensure that compatible pickup subs are provided and used on site.

- Upon arrival to the drilling site, the outside diameters of pickup subs need to be measured for compatibility with the elevators.

- Contractor and service provider job safety analysis (JSAs) and pre-job checklists need to include instructions to measure pickup subs to confirm elevator compatibility.

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

If you want to add this app to home screen tap and then ‘Add to Home Screen’.

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

On a drilling rig, a non-magnetic drill collar (NMDC) was lifted from the hydraulic catwalk with a third party pickup sub. A pickup sub is a tool that connects to other equipment and is held in the rig elevators. Normally, the top portion of the pickup sub is larger than the inside diameter of the rig elevators to prevent the pickup sub from sliding through the elevators.

The elevators and pickup sub were 6-7 meters above the rig floor at approximately a 70 degree angle when the pickup sub slipped through the elevators.

The non-magnetic drill collar slid and bounced out of the trough and landed halfway down the catwalk.

There were no injuries.

Why did it happen?

The pickup sub was undersized for the rig elevators.

Contributing factors:

- Insufficient planning and communication between the directional driller, drilling company and wellsite supervisor.

- No one had measured the outside diameter of the pickup sub to ensure it was compatible with the inside diameter of the rig elevators.

- The hazard assessment and pre-job checklists did not include pickup sub compatibility.

What did they learn?

- Drilling rig, directional drillers, service providers and producers need to work collaboratively to ensure that compatible pickup subs are provided and used on site.

- Upon arrival to the drilling site, the outside diameters of pickup subs need to be measured for compatibility with the elevators.

- Contractor and service provider job safety analysis (JSAs) and pre-job checklists need to include instructions to measure pickup subs to confirm elevator compatibility.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Published on 15/05/23

1329 Views

On a drilling rig, a non-magnetic drill collar (NMDC) was lifted from the hydraulic catwalk with a third-party pickup sub. The pickup sub slipped through the elevators. The non-magnetic drill collar slid and bounced out of the trough and landed halfway down the catwalk. There were no injuries.

Original material courtesy of Energy Safety Canada