-

What happened?

Workers on offshore wind farm turbine towers were being extracted due to bad weather.

The last person began to cross the gangway when an alarm sounded, and the traffic light turned red.

The worker continued across. When he was close to the vessel end, the gangway reached its extension limit and self-activated auto disconnection.

The equipment was programmed to slew to the right towards stow position on the vessel when disconnecting.

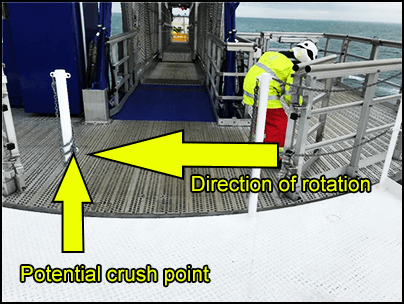

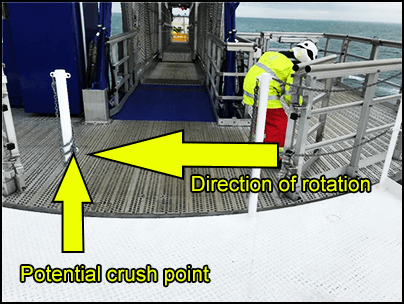

While slewing, the guard rail of the rotating platform passed by the posts on the static part of the platform with little clearance.

The worker could have been crushed when he stepped from gangway to staircase during rotation.

-

Why did it happen?

Worker was unaware of the crush hazard he exposed himself to when continuing his transfer.

The induction training was ambiguous. It was unclear to workers what they should do in case an alarm sounded:

- Either transfer to vessel when on the static part of the gangway;

- Or continue to gangway platform and await instructions to continue transfer to vessel.

Weather deteriorated faster than forecasted. Bad weather (wind noise) contributed to confusion on the gangway.

Insufficient design assessment – platform badly designed with potential crush hazard.

- Whilst slewing to the right (as programmed to do during disconnection), the guard rail of the rotating platform passed by the posts on the static part of the platform with only 19cm (0.6ft) clearance between them.

-

What did they learn?

Remove any hazards that have no safety purpose (i.e. the post that formed the hazard).

Safety training should be clear, and workers should be aware of what they need to do if an alarm sounded during transfer.

Gangway instructions can vary by manufacturer / operator, which can cause confusion amongst transferees. Ensure that workers are aware of the differences.

Contact gangway manufacturers to communicate the risk identified and suggest a revision of their design risk assessment.

-

Ask yourself or your crew

Has anything like this ever happened to you or a colleague?

What was the correct course of action for the transferee?

What other hazards are there when transferring from turbines to vessels?

Do you have any procedures or equipment that has confusing guidance? How can you address that?

How could you prevent an incident like this occurring?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Workers on offshore wind farm turbine towers were being extracted due to bad weather.

The last person began to cross the gangway when an alarm sounded, and the traffic light turned red.

The worker continued across. When he was close to the vessel end, the gangway reached its extension limit and self-activated auto disconnection.

The equipment was programmed to slew to the right towards stow position on the vessel when disconnecting.

While slewing, the guard rail of the rotating platform passed by the posts on the static part of the platform with little clearance.

The worker could have been crushed when he stepped from gangway to staircase during rotation.

Why did it happen?

Worker was unaware of the crush hazard he exposed himself to when continuing his transfer.

The induction training was ambiguous. It was unclear to workers what they should do in case an alarm sounded:

- Either transfer to vessel when on the static part of the gangway;

- Or continue to gangway platform and await instructions to continue transfer to vessel.

Weather deteriorated faster than forecasted. Bad weather (wind noise) contributed to confusion on the gangway.

Insufficient design assessment – platform badly designed with potential crush hazard.

- Whilst slewing to the right (as programmed to do during disconnection), the guard rail of the rotating platform passed by the posts on the static part of the platform with only 19cm (0.6ft) clearance between them.

What did they learn?

Remove any hazards that have no safety purpose (i.e. the post that formed the hazard).

Safety training should be clear, and workers should be aware of what they need to do if an alarm sounded during transfer.

Gangway instructions can vary by manufacturer / operator, which can cause confusion amongst transferees. Ensure that workers are aware of the differences.

Contact gangway manufacturers to communicate the risk identified and suggest a revision of their design risk assessment.

Ask yourself or your crew

Has anything like this ever happened to you or a colleague?

What was the correct course of action for the transferee?

What other hazards are there when transferring from turbines to vessels?

Do you have any procedures or equipment that has confusing guidance? How can you address that?

How could you prevent an incident like this occurring?

Workers on offshore wind farm turbine towers were being extracted due to bad weather. The last person began to cross the gangway when it auto disconnected. The worker managed to cross safely but narrowly missed being crushed.