-

What happened?

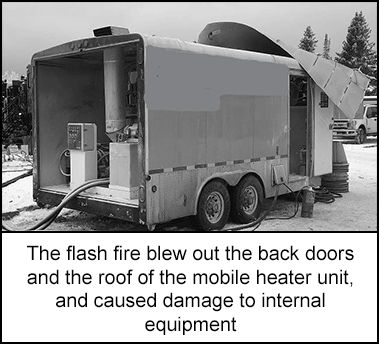

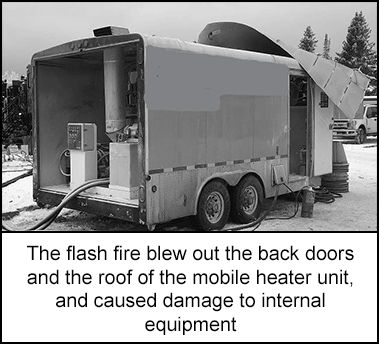

A flash fire in a mobile heater unit resulted in first and second degree burns on a worker’s face, neck and wrists.

While switching the system from diesel to natural gas the worker purged the line, thinking it contained only air. As a result, gas was purged into a closed environment, filling up the heater unit.

The gas ignited in a flash fire, burning the worker’s face, neck and wrists where they were not covered by personal protective equipment (PPE). The worker required skin grafting in areas where severe burns were sustained. This incident could have resulted in a much more severe outcome if the worker had not been wearing PPE.

-

Why did it happen?

- A site specific hazard identification was not completed prior to conducting the task.

- The worker was unaware that gas was being purged.

- The worker did not have a personal multi-gas monitor.

- Purging occurred in closed environment.

Contributing factors:

- Heater unit doors were closed due to severe cold weather.

- Not all natural gas contains odorants.

- Unknown substance was purged inside a closed environment.

- Gas detection equipment was not used.

- Electrical motor switch was turned to “on”, which created an ignition source.

- The worker went back into the area to shut off fuel source, which may have further contributed to burns on his wrists.

-

What did they learn?

- Pre-job hazard and risk assessment should be conducted prior to all tasks.

- Review safe work procedures to ensure all purging is performed in a well ventilated environment.

- Prior to starting work, develop and review fire and explosion hazard plan with workers, including use and care of personal multi-gas monitors.

- Consider the use of management of change protocols should the scope of a job change.

- Consider the use of affixed gas monitoring whenever applicable.

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

If you want to add this app to home screen tap and then ‘Add to Home Screen’.

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A flash fire in a mobile heater unit resulted in first and second degree burns on a worker’s face, neck and wrists.

While switching the system from diesel to natural gas the worker purged the line, thinking it contained only air. As a result, gas was purged into a closed environment, filling up the heater unit.

The gas ignited in a flash fire, burning the worker’s face, neck and wrists where they were not covered by personal protective equipment (PPE). The worker required skin grafting in areas where severe burns were sustained. This incident could have resulted in a much more severe outcome if the worker had not been wearing PPE.

Why did it happen?

- A site specific hazard identification was not completed prior to conducting the task.

- The worker was unaware that gas was being purged.

- The worker did not have a personal multi-gas monitor.

- Purging occurred in closed environment.

Contributing factors:

- Heater unit doors were closed due to severe cold weather.

- Not all natural gas contains odorants.

- Unknown substance was purged inside a closed environment.

- Gas detection equipment was not used.

- Electrical motor switch was turned to “on”, which created an ignition source.

- The worker went back into the area to shut off fuel source, which may have further contributed to burns on his wrists.

What did they learn?

- Pre-job hazard and risk assessment should be conducted prior to all tasks.

- Review safe work procedures to ensure all purging is performed in a well ventilated environment.

- Prior to starting work, develop and review fire and explosion hazard plan with workers, including use and care of personal multi-gas monitors.

- Consider the use of management of change protocols should the scope of a job change.

- Consider the use of affixed gas monitoring whenever applicable.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Published on 27/06/23

1400 Views

A flash fire in a mobile heater unit resulted in first and second degree burns on a worker’s face, neck and wrists. While switching the system from diesel to natural gas the worker purged the line, thinking it contained only air. As a result, gas was purged into a closed environment, filling up the heater unit. The gas ignited in a flash fire, burning the worker’s face, neck and wrists where they were not covered by personal protective equipment (PPE). The worker required skin grafting in areas where sever burns were sustained. This incident could have resulted in a much more severe outcome if the worker had not been wearing PPE.

Original material courtesy of Energy Safety Canada