-

What happened?

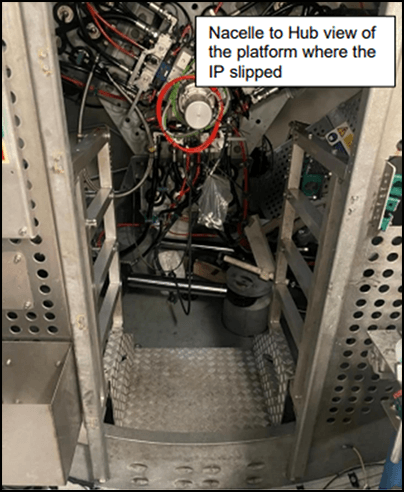

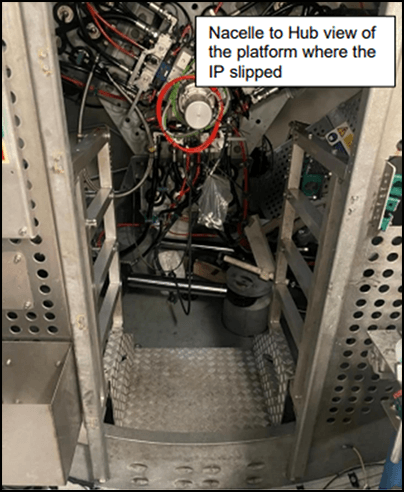

During a night shift, a technician was part of a main bearing replacement team in the hub.

While working, the technician lost his footing, slipped, and inserted a flat head electric screwdriver into his outermost right eye.

Following the incident, the technician underwent medical evaluation and, fortunately, did not suffer any permanent impact on their sight. He returned to work five days later.

-

Why did it happen?

The incident resulted from a combination of technical and human factors.

The presence of oil and grease on the workplace floor made it slippery, increasing the risk of accidents. This issue had been identified before, as numerous lessons learnt related to slippery surfaces and risks had been previously issued.

Despite corrective actions, recurrences persisted, suggesting that the measures in place were not effective enough to prevent such incidents.

The technician was working outside the maximum allowed period by the relevant directive and construction phase plan onboarding shifts, which may have contributed to unconscious fatigue while working.

-

What did they learn?

Emphasise the importance of maintaining a clean working environment to mitigate slip hazards.

Developed a dedicated policy, guideline, or instruction for offshore work hours and rest periods in the region where the incident occurred. Communicate to all teams.

Ensure strict adherence to these policies on-site.

-

Ask yourself or your crew

How can we prevent something similar from happening on our site?

In your role as a frontline worker, what proactive measures can you personally implement to ensure the work area is free from potential slip hazards?

What are some potential hazards or risks specific to offshore work hours, and how can we better address them to ensure a safer working environment?

How do you manage your work hours and rest periods during night shifts or extended shifts, and how might fatigue impact your performance and safety?

How can we improve our communication and implementation of safety policies to make the workplace safer for everyone?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During a night shift, a technician was part of a main bearing replacement team in the hub.

While working, the technician lost his footing, slipped, and inserted a flat head electric screwdriver into his outermost right eye.

Following the incident, the technician underwent medical evaluation and, fortunately, did not suffer any permanent impact on their sight. He returned to work five days later.

Why did it happen?

The incident resulted from a combination of technical and human factors.

The presence of oil and grease on the workplace floor made it slippery, increasing the risk of accidents. This issue had been identified before, as numerous lessons learnt related to slippery surfaces and risks had been previously issued.

Despite corrective actions, recurrences persisted, suggesting that the measures in place were not effective enough to prevent such incidents.

The technician was working outside the maximum allowed period by the relevant directive and construction phase plan onboarding shifts, which may have contributed to unconscious fatigue while working.

What did they learn?

Emphasise the importance of maintaining a clean working environment to mitigate slip hazards.

Developed a dedicated policy, guideline, or instruction for offshore work hours and rest periods in the region where the incident occurred. Communicate to all teams.

Ensure strict adherence to these policies on-site.

Ask yourself or your crew

How can we prevent something similar from happening on our site?

In your role as a frontline worker, what proactive measures can you personally implement to ensure the work area is free from potential slip hazards?

What are some potential hazards or risks specific to offshore work hours, and how can we better address them to ensure a safer working environment?

How do you manage your work hours and rest periods during night shifts or extended shifts, and how might fatigue impact your performance and safety?

How can we improve our communication and implementation of safety policies to make the workplace safer for everyone?

During a night shift, a technician lost his footing, slipped, and inserted a flat head electric screwdriver into his outermost right eye. Following the incident, the technician underwent medical evaluation and, fortunately, did not suffer any permanent impact on their sight. He returned to work five days later.