-

What happened?

A subsea well was being drilled from a jack-up mobile offshore drilling unit (MODU).

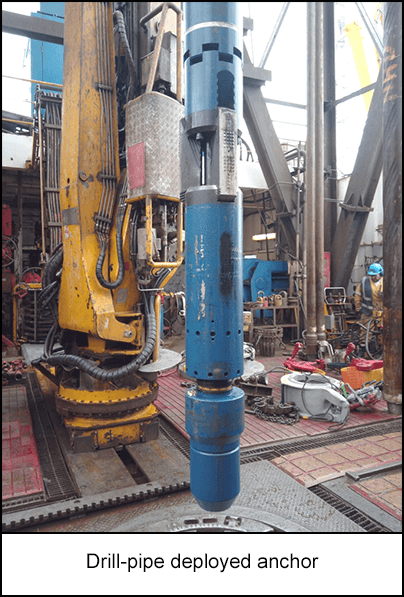

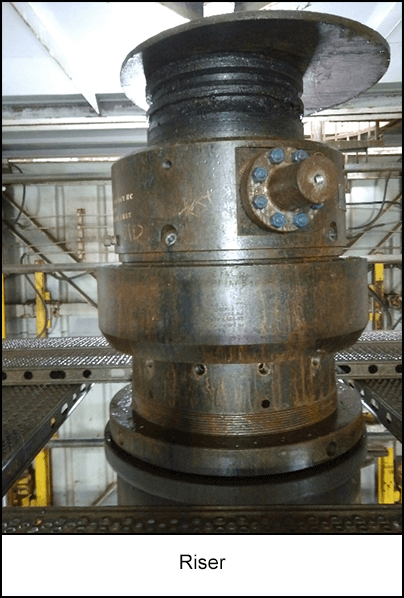

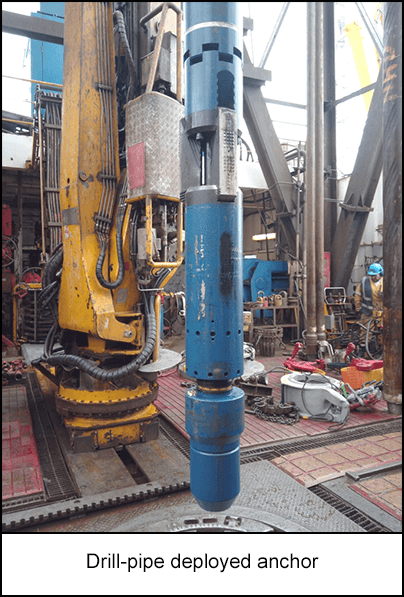

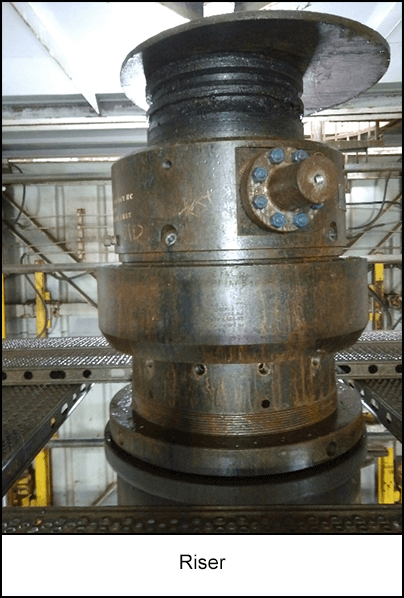

After completing the drilling, workers had to recover a 16-inch (40 cm) riser from the seabed to the surface using a drill-pipe deployed anchor tool which was inside the riser.

While pulling up the riser, the anchor tool prematurely released at a force of around 1.5 tonnes (35,000 lbs.) overpull, which was much lower than its rated capacity of 5 tonnes (114,000 lbs.).

This caused the entire riser, which was 14 metres (45 feet) long, to drop back down to the seabed.

As a result of this sudden drop, the subsea wellhead housing (WHH) sealing face was damaged.

-

Why did it happen?

The drill-pipe deployed anchor tool's load rating during operation did not match the advised value.

As a result, it failed when a relatively modest load was accidentally applied.

-

What did they learn?

Recovery of casing or riser should include constant energisation of the slip mechanism in the anchor tool by applying pressure.

Relying solely on shear pins and ratchet mechanism for tool engagement is not sufficient.

Prior to releasing risers, it is essential to ensure engagement confirmation through proper load testing.

-

Ask yourself or your crew

How can something like this happen here (e.g. on our site)?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

How do we know the risk controls/barriers are working?

What improvements or changes should we make to the procedures, controls/barriers, or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A subsea well was being drilled from a jack-up mobile offshore drilling unit (MODU).

After completing the drilling, workers had to recover a 16-inch (40 cm) riser from the seabed to the surface using a drill-pipe deployed anchor tool which was inside the riser.

While pulling up the riser, the anchor tool prematurely released at a force of around 1.5 tonnes (35,000 lbs.) overpull, which was much lower than its rated capacity of 5 tonnes (114,000 lbs.).

This caused the entire riser, which was 14 metres (45 feet) long, to drop back down to the seabed.

As a result of this sudden drop, the subsea wellhead housing (WHH) sealing face was damaged.

Why did it happen?

The drill-pipe deployed anchor tool's load rating during operation did not match the advised value.

As a result, it failed when a relatively modest load was accidentally applied.

What did they learn?

Recovery of casing or riser should include constant energisation of the slip mechanism in the anchor tool by applying pressure.

Relying solely on shear pins and ratchet mechanism for tool engagement is not sufficient.

Prior to releasing risers, it is essential to ensure engagement confirmation through proper load testing.

Ask yourself or your crew

How can something like this happen here (e.g. on our site)?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

How do we know the risk controls/barriers are working?

What improvements or changes should we make to the procedures, controls/barriers, or the way we work?

A subsea well was being drilled from a jack-up mobile offshore drilling unit (MODU). A series of events and failures led to the riser being dropped to the seabed. As a result of this sudden drop, the subsea wellhead housing sealing face was damaged.