-

What happened?

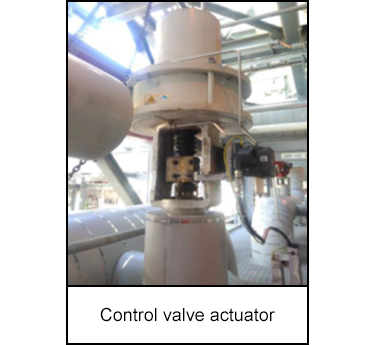

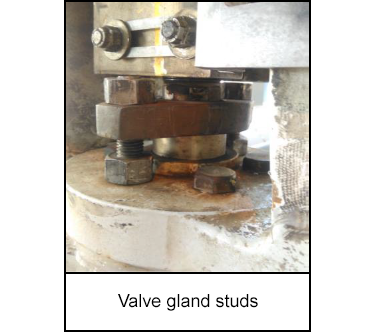

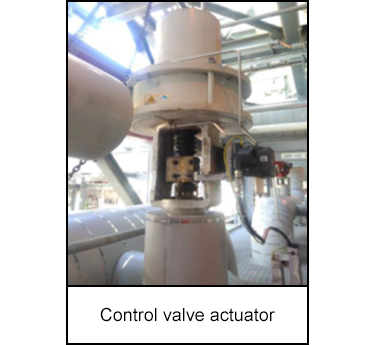

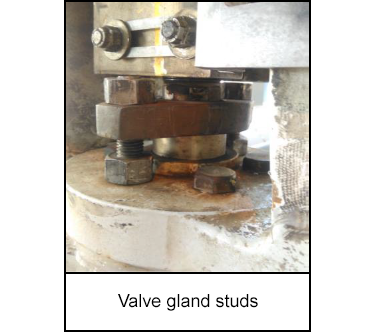

When replacing a control valve actuator, the work team identified that the valve gland studs had to be disturbed to allow for the removal of the actuator.

Following a brief conversation, the team proceeded to loosen the valve gland studs.

Loosening the valve gland allowed methane gas to be released. The methane did not ignite.

Multiple work party members were in the vicinity. None were harmed.

-

Why did it happen?

Although the work team had identified that the task would proceed differently to plan, it was not recognised that the isolations in place were insufficient for the revised work scope.

A site-specific actuator maintenance procedure did not exist.

The team had some technical competency gaps and had normalised risks associated with actuator maintenance.

-

What did they learn?

Enhance the technical competency of work teams involved in control valve actuator maintenance. Improve awareness of control valve actuator differences.

Identify all control valve actuators that require the gland to be removed to allow for actuator removal. Update the maintenance system to flag the additional isolation requirements.

Develop a site-specific work instruction for control valve removal. Refer to vendor procedures when developing this work instruction.

-

Ask yourself or your crew

Do you have control valves at your site? How many different types of control valves are on your site? Do any require the gland to be removed to allow for actuator removal? Do you have a site-specific work instruction for control valve removal?

How do you respond when a task is not proceeding as planned?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

When replacing a control valve actuator, the work team identified that the valve gland studs had to be disturbed to allow for the removal of the actuator.

Following a brief conversation, the team proceeded to loosen the valve gland studs.

Loosening the valve gland allowed methane gas to be released. The methane did not ignite.

Multiple work party members were in the vicinity. None were harmed.

Why did it happen?

Although the work team had identified that the task would proceed differently to plan, it was not recognised that the isolations in place were insufficient for the revised work scope.

A site-specific actuator maintenance procedure did not exist.

The team had some technical competency gaps and had normalised risks associated with actuator maintenance.

What did they learn?

Enhance the technical competency of work teams involved in control valve actuator maintenance. Improve awareness of control valve actuator differences.

Identify all control valve actuators that require the gland to be removed to allow for actuator removal. Update the maintenance system to flag the additional isolation requirements.

Develop a site-specific work instruction for control valve removal. Refer to vendor procedures when developing this work instruction.

Ask yourself or your crew

Do you have control valves at your site? How many different types of control valves are on your site? Do any require the gland to be removed to allow for actuator removal? Do you have a site-specific work instruction for control valve removal?

How do you respond when a task is not proceeding as planned?

While replacing a control valve actuator, a work team loosened the valve gland studs, inadvertently releasing methane gas. Fortunately, the gas did not ignite, and no one was harmed.

Original material courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/loss-of-containment-nov-2020