-

What happened?

A newly constructed gas gathering network was filled with inert nitrogen gas. During commissioning, methane was introduced at low pressure from the live network to displace the nitrogen gas.

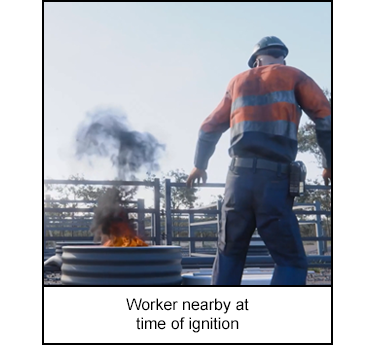

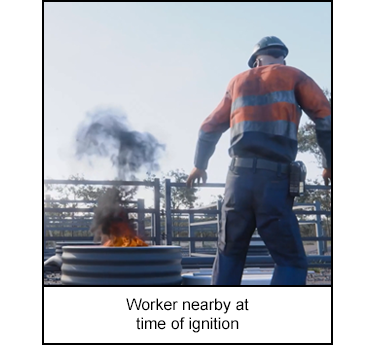

This forces the nitrogen gas to vent towards the atmosphere at vents installed throughout the network. A worker was walking towards the low pressure header (LPH) to measure the concentration of methane, when a fire ignited at a riser valve on the LPH.

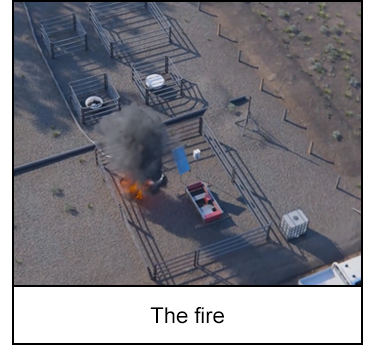

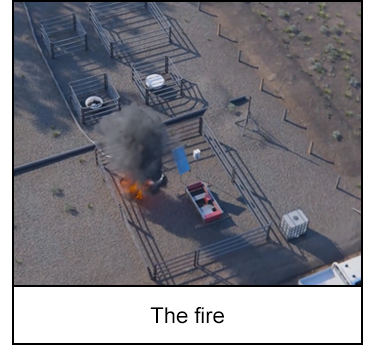

The worker was within 2 metres (6.6 feet) of the riser valve pit at the time of ignition. Away from the site of the fire, the field team isolated the main valve and second valve half way down to limit gas volumes. The fire was managed by fire emergency services until it burned out.

It reached approximately 15 metres (49 feet) in height, burning for 2 hours, severely damaging adjacent infrastructure and equipment. Nobody was hurt during this incident.

-

Why did it happen?

Flow rate of methane was higher than planned, due to a bypass being left open. The bypass did not appear on piping & instrument diagrams (P&IDs) and commissioning procedures. This contributed to both the leak and static ignition.

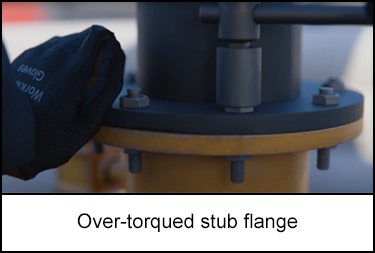

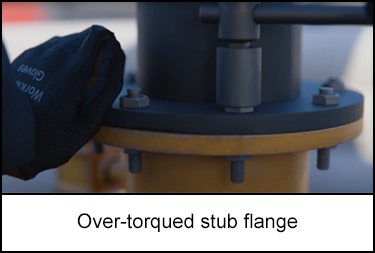

A stub flange connecting the assembly to a metal sample spool was over-torqued, likely deforming the face of the flange and allowing gas to escape. Correct torque values had not been communicated to the commissioning and start-up (CSU) field team.

Given the nature of the site, there were multiple static ignition sources present in the vent assembly and valve pit, including an unearthed metal spool, a high-density polyethylene (HDPE) pipe and the pit liner itself. Static charge built up at the low pressure header service connection valve, arced to the plastic liner and ignited the methane gas.

-

What did they learn?

Improve procedure documents to ensure they are clear, task-specific and fit-for-purpose for work teams.

Engage work teams in the development and review of procedures.

Confirm work teams are trained in the use of equipment and procedures.

Complete a design review of equipment and tools.

Confirm management of change processes are followed.

Ensure schedule reflects realistic timeframes to safely execute work.

Engage work teams in schedule development.

Require leaders to spend time in the field to understand challenges.

Ensure leaders understand the site conditions prior to decisions about the project.

Embed culture of curiosity in leaders about risks and challenges.

Improve communication and active listening skills.

-

Ask yourself or your crew

Are written procedures for commissioning activities at your workplace fit-for-purpose for the work teams that are required to use them? Are the people that do the work routinely consulted and actively involved in developing, reviewing and updating these procedures and P&IDs? Do you ‘walk the line’ to ensure P&IDs match ‘as built’?

Are work teams at your workplace consulted during the development of their work schedules, including when schedule changes occur? When schedule changes occur at your workplace, how do you ensure that safety is not compromised to accommodate the changes? Do you ever feel under schedule pressure at your workplace?

How often do senior leaders in your organisation spend time in the field?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A newly constructed gas gathering network was filled with inert nitrogen gas. During commissioning, methane was introduced at low pressure from the live network to displace the nitrogen gas.

This forces the nitrogen gas to vent towards the atmosphere at vents installed throughout the network. A worker was walking towards the low pressure header (LPH) to measure the concentration of methane, when a fire ignited at a riser valve on the LPH.

The worker was within 2 metres (6.6 feet) of the riser valve pit at the time of ignition. Away from the site of the fire, the field team isolated the main valve and second valve half way down to limit gas volumes. The fire was managed by fire emergency services until it burned out.

It reached approximately 15 metres (49 feet) in height, burning for 2 hours, severely damaging adjacent infrastructure and equipment. Nobody was hurt during this incident.

Why did it happen?

Flow rate of methane was higher than planned, due to a bypass being left open. The bypass did not appear on piping & instrument diagrams (P&IDs) and commissioning procedures. This contributed to both the leak and static ignition.

A stub flange connecting the assembly to a metal sample spool was over-torqued, likely deforming the face of the flange and allowing gas to escape. Correct torque values had not been communicated to the commissioning and start-up (CSU) field team.

Given the nature of the site, there were multiple static ignition sources present in the vent assembly and valve pit, including an unearthed metal spool, a high-density polyethylene (HDPE) pipe and the pit liner itself. Static charge built up at the low pressure header service connection valve, arced to the plastic liner and ignited the methane gas.

What did they learn?

Improve procedure documents to ensure they are clear, task-specific and fit-for-purpose for work teams.

Engage work teams in the development and review of procedures.

Confirm work teams are trained in the use of equipment and procedures.

Complete a design review of equipment and tools.

Confirm management of change processes are followed.

Ensure schedule reflects realistic timeframes to safely execute work.

Engage work teams in schedule development.

Require leaders to spend time in the field to understand challenges.

Ensure leaders understand the site conditions prior to decisions about the project.

Embed culture of curiosity in leaders about risks and challenges.

Improve communication and active listening skills.

Ask yourself or your crew

Are written procedures for commissioning activities at your workplace fit-for-purpose for the work teams that are required to use them? Are the people that do the work routinely consulted and actively involved in developing, reviewing and updating these procedures and P&IDs? Do you ‘walk the line’ to ensure P&IDs match ‘as built’?

Are work teams at your workplace consulted during the development of their work schedules, including when schedule changes occur? When schedule changes occur at your workplace, how do you ensure that safety is not compromised to accommodate the changes? Do you ever feel under schedule pressure at your workplace?

How often do senior leaders in your organisation spend time in the field?

During the commissioning of a newly constructed gas gathering network, a fire ignited at a riser valve on the low pressure header due to a methane gas leak, reaching heights of 15 metres (49 feet) and burning for 2 hours. The fire caused severe damage to adjacent infrastructure, but fortunately, no one was injured.

Original material courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/operating-process-equipment-fire-leb-toolbox