-

What happened?

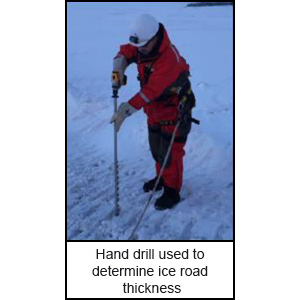

A hand-held drill was being used to check ice thickness during ice road construction.

A worker’s hand slipped causing the mitt to become caught in the rotating shaft of the drill bit.

The worker was then medically evacuated to hospital and treated for thumb dislocation and abrasion.

-

Why did it happen?

The hazard was not identified in the job safety analysis (JSA), and a permit is not required for this activity.

The tool had no side handle on the drill to aid in pulling from the ice, so a slip could have easily happened.

The worker neglected to follow the manufacturer’s guide when using the tool, resulting in their hand being placed in the line of fire.

Workers may develop a higher risk tolerance from having previously performed task incorrectly without facing any consequences. Even experienced workers can be susceptible to this.

-

What did they learn?

The correct tool should always be used for the job. Operators should be familiar and qualified to use the tool.

All personnel should understand and recognise ‘line of fire’ areas and avoid these during the job. These areas should be addressed in the JSA.

Utilise last minute risk assessment (stop and think / step back 5 X 5) during task execution.

-

Ask yourself or your crew

How could an incident like the one involving the hand-held drill occur on our site?

What do you do to ensure your training on using tools and equipment is up-to-date? What should you do if you’re not sure how to safely operate specific tools/equipment?

What can you do if you identify additional hazards not mentioned in the JSA? Who do you need to speak to, and what should happen as a result of that conversation?

How do you avoid becoming more tolerant of risk because of past mistakes without consequences when performing tasks incorrectly?

What enhancements or adjustments should we consider implementing to our procedures, controls, or work practices to further enhance safety in our activities?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A hand-held drill was being used to check ice thickness during ice road construction.

A worker’s hand slipped causing the mitt to become caught in the rotating shaft of the drill bit.

The worker was then medically evacuated to hospital and treated for thumb dislocation and abrasion.

Why did it happen?

The hazard was not identified in the job safety analysis (JSA), and a permit is not required for this activity.

The tool had no side handle on the drill to aid in pulling from the ice, so a slip could have easily happened.

The worker neglected to follow the manufacturer’s guide when using the tool, resulting in their hand being placed in the line of fire.

Workers may develop a higher risk tolerance from having previously performed task incorrectly without facing any consequences. Even experienced workers can be susceptible to this.

What did they learn?

The correct tool should always be used for the job. Operators should be familiar and qualified to use the tool.

All personnel should understand and recognise ‘line of fire’ areas and avoid these during the job. These areas should be addressed in the JSA.

Utilise last minute risk assessment (stop and think / step back 5 X 5) during task execution.

Ask yourself or your crew

How could an incident like the one involving the hand-held drill occur on our site?

What do you do to ensure your training on using tools and equipment is up-to-date? What should you do if you’re not sure how to safely operate specific tools/equipment?

What can you do if you identify additional hazards not mentioned in the JSA? Who do you need to speak to, and what should happen as a result of that conversation?

How do you avoid becoming more tolerant of risk because of past mistakes without consequences when performing tasks incorrectly?

What enhancements or adjustments should we consider implementing to our procedures, controls, or work practices to further enhance safety in our activities?

During ice road construction, a hand-held drill was utilised to check ice thickness. A worker's hand slipped while handling the tool, leading to their mitten becoming entangled in the rotating shaft of the drill bit. Subsequently, the worker required medical evacuation to the hospital for treatment of thumb dislocation and abrasion.