-

What happened?

Whilst a chain hook was being suspended during lifting operations on a vessel, a swell came through which caused the vessel to rise.

The chain hook was run from a heave compensated rooster box. The chain lowered, allowing a link to become snagged between the drill floor plating and deck grating.

The chain snapped back under pressure and narrowly missed crew members.

-

Why did it happen?

The chain became caught in the deck gratings when the rooster box rose relative to the deck.

The chain snapped back under pressure.

The technician unhooking the chain was not trained to do so but wanted to help and support.

- He unhooked the chain without ensuring it was fed back to the rooster box. The chain was left to dangle.

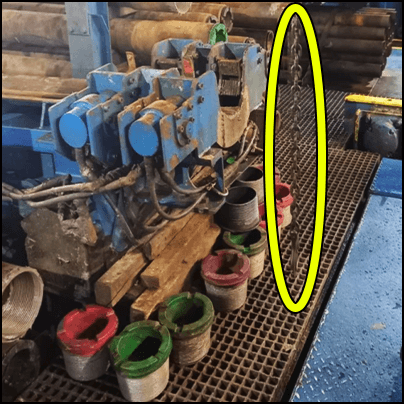

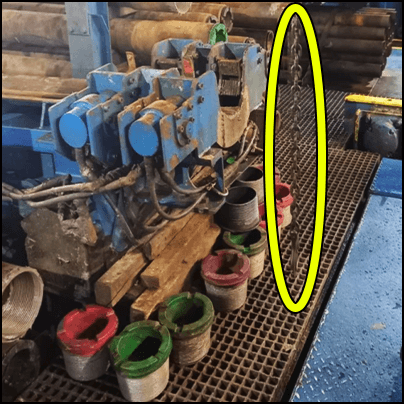

- There were gaps in the deck gratings (see image), allowing the chain to catch on the deck.

Lack of supervision – the untrained worker was not supervised.

-

What did they learn?

Ensure adequate supervision during lifting operations.

Workers should not support operations outside of their competencies.

Supervisors should not allow workers to carry out activities they are not trained for.

-

Ask yourself or your crew

Think of a time when you helped with a task that you were not trained for. What could have happened?

What should you do if you observe a colleague performing a task that he/she is not adequately trained for?

What hazards are there with chain hooks run from heave compensated rooster boxes?

What hazards should you look out for during lifting operations?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Whilst a chain hook was being suspended during lifting operations on a vessel, a swell came through which caused the vessel to rise.

The chain hook was run from a heave compensated rooster box. The chain lowered, allowing a link to become snagged between the drill floor plating and deck grating.

The chain snapped back under pressure and narrowly missed crew members.

Why did it happen?

The chain became caught in the deck gratings when the rooster box rose relative to the deck.

The chain snapped back under pressure.

The technician unhooking the chain was not trained to do so but wanted to help and support.

- He unhooked the chain without ensuring it was fed back to the rooster box. The chain was left to dangle.

- There were gaps in the deck gratings (see image), allowing the chain to catch on the deck.

Lack of supervision – the untrained worker was not supervised.

What did they learn?

Ensure adequate supervision during lifting operations.

Workers should not support operations outside of their competencies.

Supervisors should not allow workers to carry out activities they are not trained for.

Ask yourself or your crew

Think of a time when you helped with a task that you were not trained for. What could have happened?

What should you do if you observe a colleague performing a task that he/she is not adequately trained for?

What hazards are there with chain hooks run from heave compensated rooster boxes?

What hazards should you look out for during lifting operations?

During lifting operations on a vessel, a swell came through which caused the vessel to rise. The chain lowered, allowing a link to become snagged between the drill floor plating and deck grating. The chain snapped back under pressure and narrowly missed crew members.