-

What happened?

A jockey wheel assembly became detached from a service trailer being towed on a public road.

The driver of a light vehicle (LV) behind the trailer braked heavily and took evasive manoeuvres to avoid impact with the jockey wheel assembly.

Both vehicles were travelling at almost 100 km/h (62 mph) at the time of the incident.

-

Why did it happen?

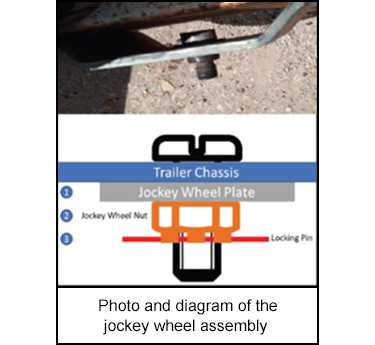

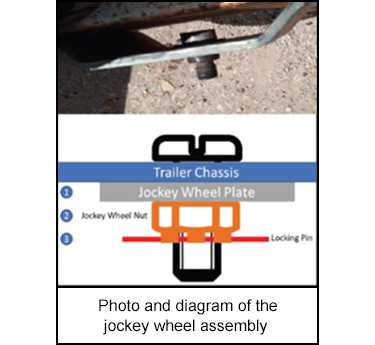

The locking pin that secures the jockey wheel assembly had released from the assembly during transit.

Use of the trailer had increased from occasional to daily after replacing a service truck.

The trailer remained on an annual service schedule.

The trailer traverses a range of road conditions (sealed, unsealed and access tracks) during transit.

Road conditions can increase the wear and tear of components.

-

What did they learn?

Explore alternatives to transporting equipment or tools in trailers.

Replace jockey wheel assemblies with a clamp-type design which is secured to the trailer draw bar by four bolts.

Maintenance strategy should reflect usage of trailers and address wear and tear.

-

Ask yourself or your crew

What checks do you conduct prior to starting a journey? Do they include trailers? Do you check that all loose objects are secured?

Does your trailer jockey wheel assembly have a clamp-type design which is secured to the trailer draw bar by four bolts?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A jockey wheel assembly became detached from a service trailer being towed on a public road.

The driver of a light vehicle (LV) behind the trailer braked heavily and took evasive manoeuvres to avoid impact with the jockey wheel assembly.

Both vehicles were travelling at almost 100 km/h (62 mph) at the time of the incident.

Why did it happen?

The locking pin that secures the jockey wheel assembly had released from the assembly during transit.

Use of the trailer had increased from occasional to daily after replacing a service truck.

The trailer remained on an annual service schedule.

The trailer traverses a range of road conditions (sealed, unsealed and access tracks) during transit.

Road conditions can increase the wear and tear of components.

What did they learn?

Explore alternatives to transporting equipment or tools in trailers.

Replace jockey wheel assemblies with a clamp-type design which is secured to the trailer draw bar by four bolts.

Maintenance strategy should reflect usage of trailers and address wear and tear.

Ask yourself or your crew

What checks do you conduct prior to starting a journey? Do they include trailers? Do you check that all loose objects are secured?

Does your trailer jockey wheel assembly have a clamp-type design which is secured to the trailer draw bar by four bolts?

A jockey wheel assembly detached from a service trailer on a public road. The driver of a light vehicle behind had to brake heavily and swerve to avoid it. Both vehicles were traveling at nearly 100 km/h (62 mph).

Original material courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/driving-collision-learning-event-bulletin-2