-

What happened?

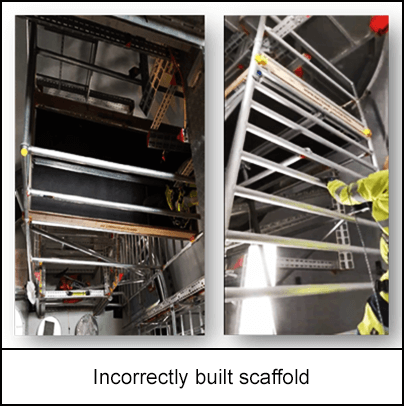

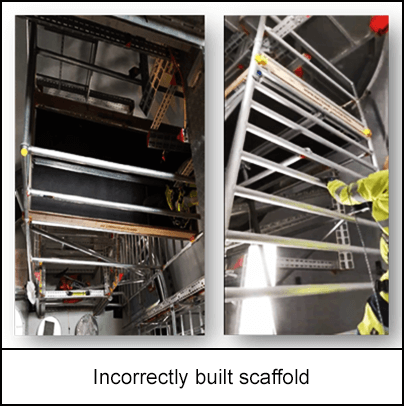

During turbine installation, a scaffold was meant to be used to access a difficult to reach location.

The original design had to be modified, and the modifications were carried out without consulting all involved parties.

When work commenced, it was discovered that the modified scaffold was not fit for purpose as it did not allow safe access. To access the top of the scaffold, technicians would have had to climb outside the scaffold and wear a fall arrest harness, which defeated the purpose of building the structure.

The scaffold required further modifications before work could start. The project was stopped while further actions were considered, which led to downtime for the contractors.

-

Why did it happen?

Poor communication between the design team, other involved parties, and contractor - modifications were made without a discussion between all involved parties, resulting in the scaffold being unsafe to use.

-

What did they learn?

If work conditions change, stop the job, and reassess the risks.

Ensure that all concerned parties are involved in design changes. Consider all stages from manufacturing, installation, commissioning, and operations.

If external solutions such as scaffolds are required, this should be fully addressed and solved in the design phase and be a part of the design risk assessment.

Residual design risks should be carried over to the project, contractors, operations and maintenance (O&M) via the design risk assessment.

-

Ask yourself or your crew

How can something like this happen here?

Has the use of temporary platforms been discussed and eliminated where possible?

Is the scaffold we use a short-term or long-term solution? If long-term, what other uses might it have?

What should be considered if the scaffold design has to be modified at any stage during its time in position?

What is our process for signing off designs (think of the teams involved, how they communicate and collaborate)? How can we improve?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During turbine installation, a scaffold was meant to be used to access a difficult to reach location.

The original design had to be modified, and the modifications were carried out without consulting all involved parties.

When work commenced, it was discovered that the modified scaffold was not fit for purpose as it did not allow safe access. To access the top of the scaffold, technicians would have had to climb outside the scaffold and wear a fall arrest harness, which defeated the purpose of building the structure.

The scaffold required further modifications before work could start. The project was stopped while further actions were considered, which led to downtime for the contractors.

Why did it happen?

Poor communication between the design team, other involved parties, and contractor - modifications were made without a discussion between all involved parties, resulting in the scaffold being unsafe to use.

What did they learn?

If work conditions change, stop the job, and reassess the risks.

Ensure that all concerned parties are involved in design changes. Consider all stages from manufacturing, installation, commissioning, and operations.

If external solutions such as scaffolds are required, this should be fully addressed and solved in the design phase and be a part of the design risk assessment.

Residual design risks should be carried over to the project, contractors, operations and maintenance (O&M) via the design risk assessment.

Ask yourself or your crew

How can something like this happen here?

Has the use of temporary platforms been discussed and eliminated where possible?

Is the scaffold we use a short-term or long-term solution? If long-term, what other uses might it have?

What should be considered if the scaffold design has to be modified at any stage during its time in position?

What is our process for signing off designs (think of the teams involved, how they communicate and collaborate)? How can we improve?

A scaffold was meant to be used to access a difficult to reach location during turbine installation. The original scaffold design had to be modified, and the modifications were carried out without consulting all involved parties. The modified structure proved to be unsafe and had to be further altered, which caused delays to the project.