-

What happened?

A hydraulic flying lead umbilical hosebun broke free while being hoisted for deployment.

The crane block was at 30 feet (9 metres) height at the time.

The umbilical struck a worker on the side of his hardhat and left shoulder, coming to rest on the moonpool deck.

-

Why did it happen?

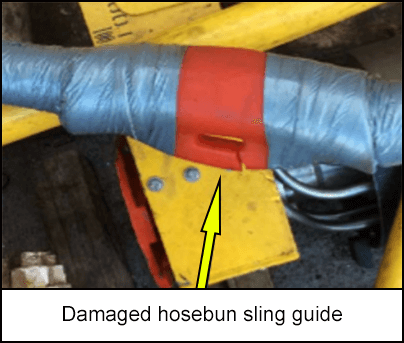

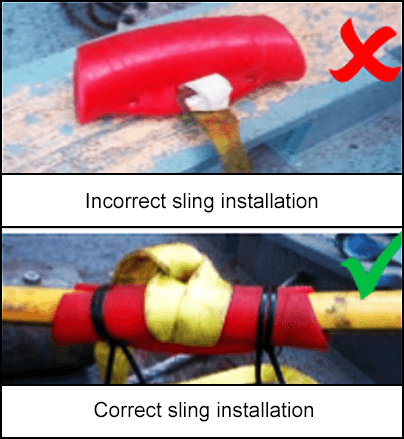

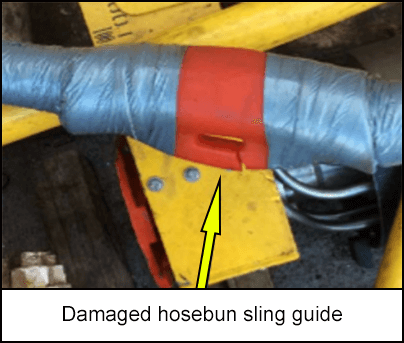

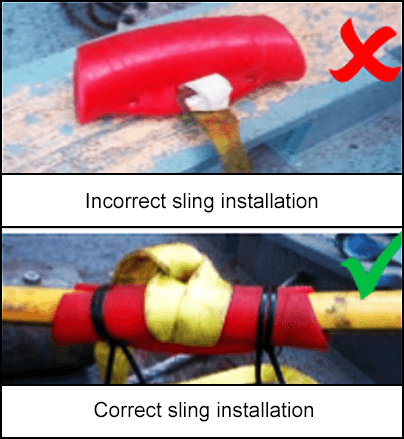

The sling was too short for correct installation. Instead of being wrapped around the hosebun and umbilical, it was attached to the sling guide, which was not a designated safe lifting point.

Installation instructions were not included in the hose hosebun packages, and work instructions were not specific enough to allow the incorrect configuration to be identified during pre-work checks.

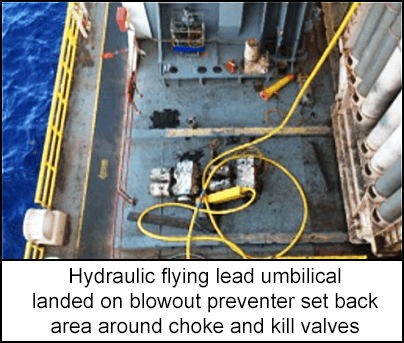

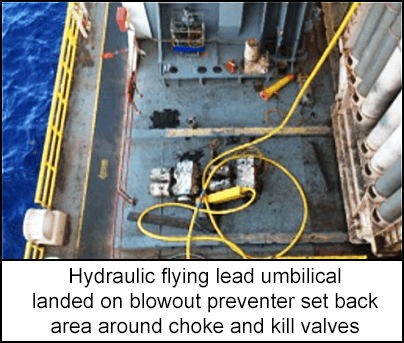

Extra equipment in the work area (choke and kill valves) influenced workers to enter the cone of exposure. They didn’t stop the job.

-

What did they learn?

Verify equipment is correctly configured – do not assume. If the correct procedure is not available, stop the job until correct use is understood.

Verify work conditions are met as part of the job setup (e.g. a clear work area so workers can stay out of the cone of exposure).

Develop specific work instructions for hydraulic flying lead umbilical rig up, including correct sling configuration.

Work with equipment vendors to include installation instructions in packages.

Revise existing safe work practices around drops cone of exposure, checklists and job safety analysis for verification of correct hosebun rigging.

-

Ask yourself or your crew

How can something like this happen here? What would be the consequences?

Have you observed any equipment on-site that has been incorrectly configured?

How can you check that rigging equipment has been correctly configured? If you install it yourself, what instructions do you use?

What pre-checks do you conduct before lifting operations? What more can you do?

What other hazards are there during our lifting operations, and what measures do we have in place to mitigate those?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A hydraulic flying lead umbilical hosebun broke free while being hoisted for deployment.

The crane block was at 30 feet (9 metres) height at the time.

The umbilical struck a worker on the side of his hardhat and left shoulder, coming to rest on the moonpool deck.

Why did it happen?

The sling was too short for correct installation. Instead of being wrapped around the hosebun and umbilical, it was attached to the sling guide, which was not a designated safe lifting point.

Installation instructions were not included in the hose hosebun packages, and work instructions were not specific enough to allow the incorrect configuration to be identified during pre-work checks.

Extra equipment in the work area (choke and kill valves) influenced workers to enter the cone of exposure. They didn’t stop the job.

What did they learn?

Verify equipment is correctly configured – do not assume. If the correct procedure is not available, stop the job until correct use is understood.

Verify work conditions are met as part of the job setup (e.g. a clear work area so workers can stay out of the cone of exposure).

Develop specific work instructions for hydraulic flying lead umbilical rig up, including correct sling configuration.

Work with equipment vendors to include installation instructions in packages.

Revise existing safe work practices around drops cone of exposure, checklists and job safety analysis for verification of correct hosebun rigging.

Ask yourself or your crew

How can something like this happen here? What would be the consequences?

Have you observed any equipment on-site that has been incorrectly configured?

How can you check that rigging equipment has been correctly configured? If you install it yourself, what instructions do you use?

What pre-checks do you conduct before lifting operations? What more can you do?

What other hazards are there during our lifting operations, and what measures do we have in place to mitigate those?

A hydraulic flying lead umbilical hosebun broke free while being hoisted for deployment. It struck a worker on his hardhat and left shoulder.