-

What happened?

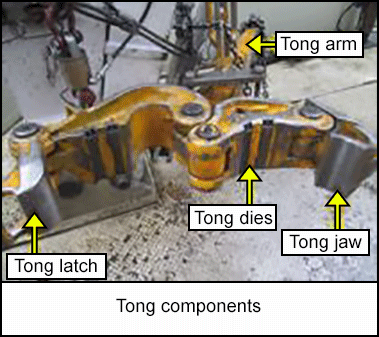

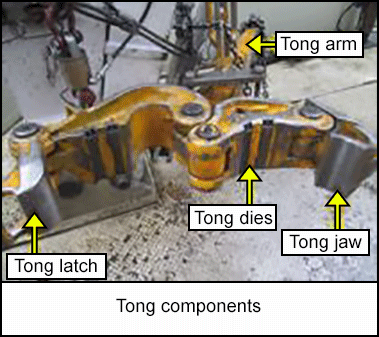

As a driller broke the tool joint connection, the tong dies slipped and the tong swung violently, striking the bottom hole assembly (BHA). This caused the tong arm to swing towards the drawworks.

-

Why did it happen?

The wrong tong jaw was in the breakout side tongs.

Two sizes of jaws fit the BHA tool joint connection. Either set of jaws can be used because of the various outside diameters (ODs) of the BHA components, the jaws used were not the best fit of the two options.

-

What did they learn?

In the drilling industry, it is common to have multiple ODs of the same nominal size pipe. However, tongs should be inspected each time after switching jaws to ensure the correct fit.

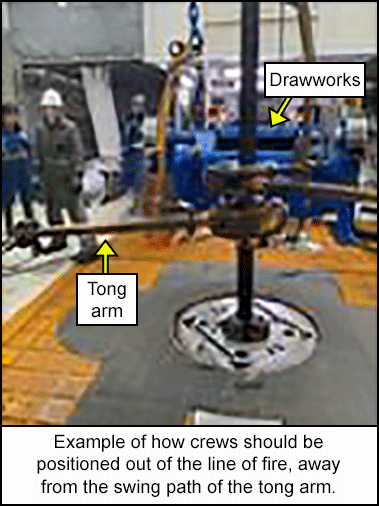

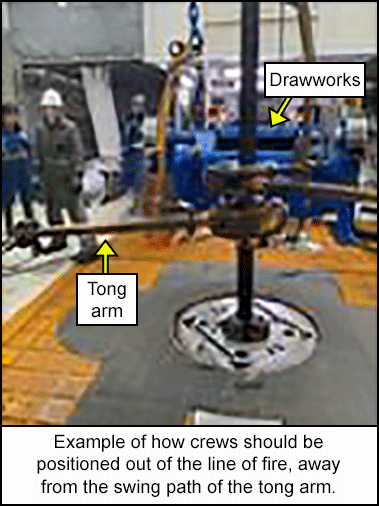

Line of fire procedures were followed — the floor around operations was clear and workers were well back of the swing path of the tong arms — which prevented potential injuries.

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

As a driller broke the tool joint connection, the tong dies slipped and the tong swung violently, striking the bottom hole assembly (BHA). This caused the tong arm to swing towards the drawworks.

Why did it happen?

The wrong tong jaw was in the breakout side tongs.

Two sizes of jaws fit the BHA tool joint connection. Either set of jaws can be used because of the various outside diameters (ODs) of the BHA components, the jaws used were not the best fit of the two options.

What did they learn?

In the drilling industry, it is common to have multiple ODs of the same nominal size pipe. However, tongs should be inspected each time after switching jaws to ensure the correct fit.

Line of fire procedures were followed — the floor around operations was clear and workers were well back of the swing path of the tong arms — which prevented potential injuries.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

As a driller broke the tool joint connection, the tool dies slipped and the tong swung violently striking the bottom hole assembly. This caused the tong arm to swing towards the draw works.

Original material courtesy of Energy Safety Canada