-

What happened?

A rope access team (RAT) were involved in a workscope which involved an outboard activity. This job required the wearing of lifejackets fitted with personal locator beacons (PLBs).

The team carried out thorough pre-use checks of their equipment, as per procedure, and identified two significant problems:

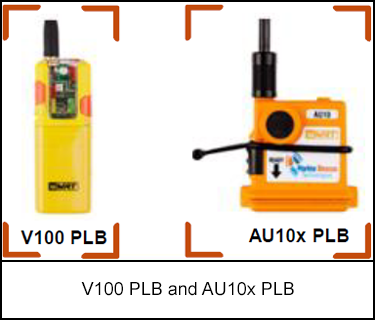

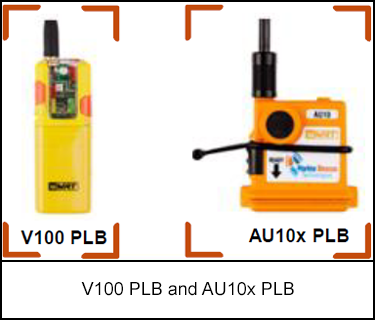

- Two of the jackets were fitted with V100 PLBs instead of the correct AU10x PLB (V100 is only designated for use in the renewables sector and the emergency response and rescue vessel (ERRV), which was providing rescue cover for this task, can only pick up the signal from the AU10x).

- One of the lifejackets had out-of-date certification.

These lifejackets were all removed from service and placed in quarantine. Alternative equipment was sourced, and the job was carried out safely.

-

Why did it happen?

The lifejacket stores area, onshore, had been reorganised and no management of change was undertaken.

The lifejacket storage units had been relocated, and incorrect labelling was attached to them, allowing the two types of PLB to be mixed up.

The personnel selecting the lifejackets for issue believed they had taken the correct ones but failed to thoroughly check them.

The lifejacket with the out-of-date certification had not been identified prior to dispatch.

What Went Right:

- The RATs carried out thorough pre-use checks of their equipment, as per procedure, identifying the problem

- The incorrect and out-of-certification equipment was removed from service and quarantined

-

What did they learn?

Ensure management of change is undertaken when rearranging any storage locations.

Ensure that a competent person thoroughly examines all returned equipment.

Ensure check sheets prompt additional checks for the correct PLB.

Undertake periodic audits of stores areas.

-

Ask yourself or your crew

How can something like this happen here (e.g. on our site)?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

How do we know the risk controls/barriers are working?

What improvements or changes should we make to the procedures, controls/barriers, or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A rope access team (RAT) were involved in a workscope which involved an outboard activity. This job required the wearing of lifejackets fitted with personal locator beacons (PLBs).

The team carried out thorough pre-use checks of their equipment, as per procedure, and identified two significant problems:

- Two of the jackets were fitted with V100 PLBs instead of the correct AU10x PLB (V100 is only designated for use in the renewables sector and the emergency response and rescue vessel (ERRV), which was providing rescue cover for this task, can only pick up the signal from the AU10x).

- One of the lifejackets had out-of-date certification.

These lifejackets were all removed from service and placed in quarantine. Alternative equipment was sourced, and the job was carried out safely.

Why did it happen?

The lifejacket stores area, onshore, had been reorganised and no management of change was undertaken.

The lifejacket storage units had been relocated, and incorrect labelling was attached to them, allowing the two types of PLB to be mixed up.

The personnel selecting the lifejackets for issue believed they had taken the correct ones but failed to thoroughly check them.

The lifejacket with the out-of-date certification had not been identified prior to dispatch.

What Went Right:

- The RATs carried out thorough pre-use checks of their equipment, as per procedure, identifying the problem

- The incorrect and out-of-certification equipment was removed from service and quarantined

What did they learn?

Ensure management of change is undertaken when rearranging any storage locations.

Ensure that a competent person thoroughly examines all returned equipment.

Ensure check sheets prompt additional checks for the correct PLB.

Undertake periodic audits of stores areas.

Ask yourself or your crew

How can something like this happen here (e.g. on our site)?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

How do we know the risk controls/barriers are working?

What improvements or changes should we make to the procedures, controls/barriers, or the way we work?

During a rope access task involving outboard work, a pre-use inspection identified two lifejackets fitted with incorrect personal locator beacons (PLBs) and one with expired certification. The issue arose due to poor equipment management following a reorganisation of the onshore storage area, including mislabelling and a lack of formal equipment checks; the faulty gear was quarantined, and the job was completed safely using suitable replacements.