-

What happened?

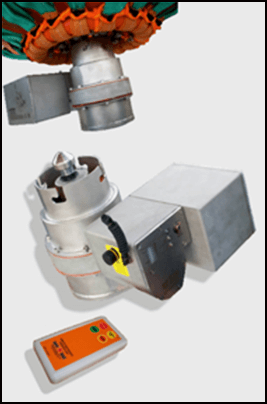

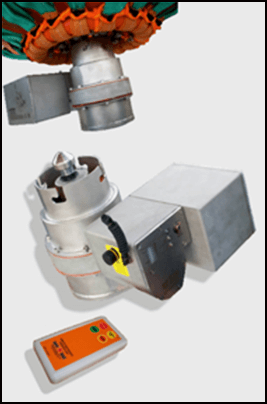

Two technicians were carrying out a dynamic load test on a transition piece (TP) davit crane using a load test waterbag.

Technician A was operating the remote control of the crane and technician B was operating the waterbag.

After successful completion of dynamic load tests, the water should be drained from the waterbags.

The technician pulled on a discharging valve tether line to release the water. The waterbag suddenly dropped uncontrollably.

The discharging valve tether line shifted rapidly and got entangled around the technician’s hand causing severe hand injury.

The emergency backpack was brought for first aid/emergency medical response and evacuation was initiated immediately.

-

Why did it happen?

The hydraulic winch (load cells) of the davit crane was not working correctly.

A remote discharging unit was not used/available and was replaced with the discharging valve tether line.

The main discharging valve tether line didn’t have the correct length to operate the discharging of water safely.

The extended discharging rope didn’t have the correct thickness according to the manufacturing recommendations.

Technician didn’t have the generic crane user or maintenance training.

The risk assessment method statement (RAMS) was not updated to reflect the different type of lift bag used in the operation.

Lack of supervision of the operation.

-

What did they learn?

Ensure that:

- all personnel are competent and correctly trained for the service tasks.

- all purchased equipment/tools have the correct specification as required for the job.

- a risk assessment is done prior to purchase and matches the equipment being used.

- RAMS are fully up-to-date and specific for the work activities to be completed.

- only competent/qualified persons make adjustments to equipment/tools according to manufacturing recommendations.

STOP the work if the required equipment/tools are not available.

Implement the use of remote discharging unit to eliminate the need for manual handling of water release.

Hold toolbox talks before the operations. Discuss the risk of entanglement when using ropes.

-

Ask yourself or your crew

How can something like this happen here?

What should you do if the required equipment/tools required to perform the task safely are not available?

Who can initiate the “STOP work” process? When is it safe to resume work?

How can you check that:

- The RAMS is specific for the task(s) you are about to perform?

- The equipment used is maintained in compliance with legislation?

What should you do if your or your colleagues are not trained/competent to perform a task?

What improvements or changes should we make to the procedures, controls/barriers, or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Two technicians were carrying out a dynamic load test on a transition piece (TP) davit crane using a load test waterbag.

Technician A was operating the remote control of the crane and technician B was operating the waterbag.

After successful completion of dynamic load tests, the water should be drained from the waterbags.

The technician pulled on a discharging valve tether line to release the water. The waterbag suddenly dropped uncontrollably.

The discharging valve tether line shifted rapidly and got entangled around the technician’s hand causing severe hand injury.

The emergency backpack was brought for first aid/emergency medical response and evacuation was initiated immediately.

Why did it happen?

The hydraulic winch (load cells) of the davit crane was not working correctly.

A remote discharging unit was not used/available and was replaced with the discharging valve tether line.

The main discharging valve tether line didn’t have the correct length to operate the discharging of water safely.

The extended discharging rope didn’t have the correct thickness according to the manufacturing recommendations.

Technician didn’t have the generic crane user or maintenance training.

The risk assessment method statement (RAMS) was not updated to reflect the different type of lift bag used in the operation.

Lack of supervision of the operation.

What did they learn?

Ensure that:

- all personnel are competent and correctly trained for the service tasks.

- all purchased equipment/tools have the correct specification as required for the job.

- a risk assessment is done prior to purchase and matches the equipment being used.

- RAMS are fully up-to-date and specific for the work activities to be completed.

- only competent/qualified persons make adjustments to equipment/tools according to manufacturing recommendations.

STOP the work if the required equipment/tools are not available.

Implement the use of remote discharging unit to eliminate the need for manual handling of water release.

Hold toolbox talks before the operations. Discuss the risk of entanglement when using ropes.

Ask yourself or your crew

How can something like this happen here?

What should you do if the required equipment/tools required to perform the task safely are not available?

Who can initiate the “STOP work” process? When is it safe to resume work?

How can you check that:

- The RAMS is specific for the task(s) you are about to perform?

- The equipment used is maintained in compliance with legislation?

What should you do if your or your colleagues are not trained/competent to perform a task?

What improvements or changes should we make to the procedures, controls/barriers, or the way we work?

Two technicians were carrying out a dynamic load test on a transition piece (TP) davit crane using a load test waterbag. The waterbag dropped uncontrollably allowing a rope to shift rapidly. The rope got entangled around a technician’s hand causing injury.