-

What happened?

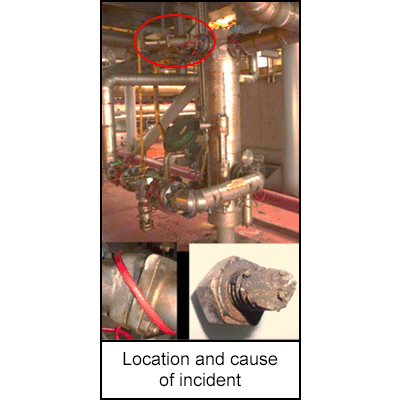

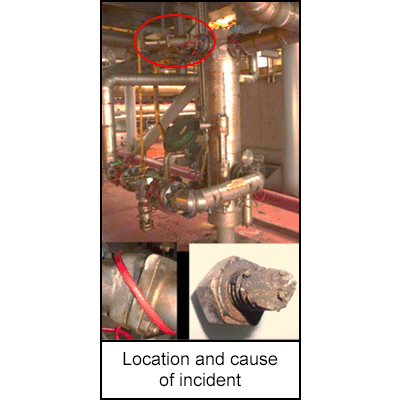

A gas compressor was in operation on an offshore installation.

The pressure safety valve bolts (304SS) were in place since installation (approximately 10 years).

Gas compressor B was operating at the time of the incident. Gas compressor A was offline due to a dry gas seal issue.

The fuel gas filter skid was operating around 28 Bar (406 psi).

2 of 4 bolts failed on the pressure safety valve body resulting in hydrocarbon being released.

The release was detected by an Area Operator who notified the Control Room Operator to shut it down.

No personnel were injured.

-

Why did it happen?

Pressure safety valve bolts were not identified for replacement when an alert was issued to replace 304SS bolts in marine environments due to chloride stress corrosion cracking.

The fuel gas filter skid (vendor package) details were not on the piping and instrumentation diagrams, vendor drawings / information was not available, and it was not included in the preventative maintenance program.

No gas detection was available in the area to detect gas release and prevent potential escalation.

-

What did they learn?

Confirm proper metallurgy of studs/nuts in marine environment process areas, and replace where issues are identified.

Verify that process equipment/piping is included on the piping and instrumentation diagrams and that support information/details are available.

Make HAZOP changes/updates to piping and instrumentation diagrams to confirm that loss prevention safeguards are sufficient (e.g., gas detection coverage).

-

Ask yourself or your crew

What can we do to avoid this happening here?

What steps would we take if this were to happen?

Although no one was injured in this situation, what could the worst-case scenario have been?

How often do we inspect our pressure safety valves for potential maintenance/replacements?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A gas compressor was in operation on an offshore installation.

The pressure safety valve bolts (304SS) were in place since installation (approximately 10 years).

Gas compressor B was operating at the time of the incident. Gas compressor A was offline due to a dry gas seal issue.

The fuel gas filter skid was operating around 28 Bar (406 psi).

2 of 4 bolts failed on the pressure safety valve body resulting in hydrocarbon being released.

The release was detected by an Area Operator who notified the Control Room Operator to shut it down.

No personnel were injured.

Why did it happen?

Pressure safety valve bolts were not identified for replacement when an alert was issued to replace 304SS bolts in marine environments due to chloride stress corrosion cracking.

The fuel gas filter skid (vendor package) details were not on the piping and instrumentation diagrams, vendor drawings / information was not available, and it was not included in the preventative maintenance program.

No gas detection was available in the area to detect gas release and prevent potential escalation.

What did they learn?

Confirm proper metallurgy of studs/nuts in marine environment process areas, and replace where issues are identified.

Verify that process equipment/piping is included on the piping and instrumentation diagrams and that support information/details are available.

Make HAZOP changes/updates to piping and instrumentation diagrams to confirm that loss prevention safeguards are sufficient (e.g., gas detection coverage).

Ask yourself or your crew

What can we do to avoid this happening here?

What steps would we take if this were to happen?

Although no one was injured in this situation, what could the worst-case scenario have been?

How often do we inspect our pressure safety valves for potential maintenance/replacements?

Pressure safety valve bolts (304SS) were in place since installation (approximately 10 years). 2 of 4 bolts failed on the pressure safety valve body resulting in gas release.