-

What happened?

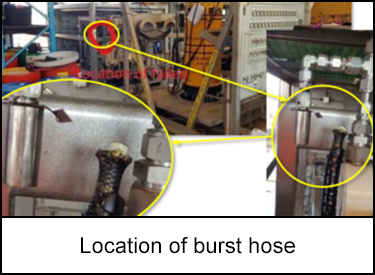

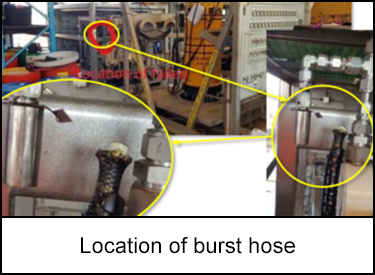

During equipment testing and maintenance in a warehouse, a 379 bar (5,496 psi) rated hydraulic hose burst on a hydraulic power unit (HPU).

The hose failed by separating at the ferrule connecting the hose to the hydraulic low pressure (crimped) termination fitting.

The technician executing the task was approximately 20 metres (66 feet) away from the unit behind the control panel barrier when the hose separated.

The area was made safe by shutting off the HPU, isolating pressure, bleeding off stored pressure in the machinery (once identified safe to do so), and cleaning up the residual fluid.

-

Why did it happen?

The equipment’s maintenance and inspection program did not explicitly state a requirement for specific hose testing or routine replacement of hoses.

Regular visual inspections, as part of the HPU planned maintenance program, had not identified that the hose needed to be replaced due to “wear and tear”.

-

What did they learn?

Improvements identified in standards, procedures and work instructions.

Verify robustness of flexible hose assembly management practices for hydraulic power units and hose spares in storage.

Update requirements in the preventative maintenance system for HPUs and hose spares to ensure condition and age of flexible hoses is adequately addressed.

-

Ask yourself or your crew

Do you work on or near hydraulic systems? Do you and your work mates regularly discuss the potential hazards and risks associated with hydraulic systems? What controls do you have in place to manage these risks?

Do you always follow the manufacturer’s instructions on assembly, operation and maintenance of HPUs?

How often do you inspect the hydraulic hoses of HPUs? What is included in the inspection criteria? What is their life span? When are they due to be replaced?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During equipment testing and maintenance in a warehouse, a 379 bar (5,496 psi) rated hydraulic hose burst on a hydraulic power unit (HPU).

The hose failed by separating at the ferrule connecting the hose to the hydraulic low pressure (crimped) termination fitting.

The technician executing the task was approximately 20 metres (66 feet) away from the unit behind the control panel barrier when the hose separated.

The area was made safe by shutting off the HPU, isolating pressure, bleeding off stored pressure in the machinery (once identified safe to do so), and cleaning up the residual fluid.

Why did it happen?

The equipment’s maintenance and inspection program did not explicitly state a requirement for specific hose testing or routine replacement of hoses.

Regular visual inspections, as part of the HPU planned maintenance program, had not identified that the hose needed to be replaced due to “wear and tear”.

What did they learn?

Improvements identified in standards, procedures and work instructions.

Verify robustness of flexible hose assembly management practices for hydraulic power units and hose spares in storage.

Update requirements in the preventative maintenance system for HPUs and hose spares to ensure condition and age of flexible hoses is adequately addressed.

Ask yourself or your crew

Do you work on or near hydraulic systems? Do you and your work mates regularly discuss the potential hazards and risks associated with hydraulic systems? What controls do you have in place to manage these risks?

Do you always follow the manufacturer’s instructions on assembly, operation and maintenance of HPUs?

How often do you inspect the hydraulic hoses of HPUs? What is included in the inspection criteria? What is their life span? When are they due to be replaced?

During equipment testing in a warehouse, a 379 bar (5,496 psi) hydraulic hose burst on a hydraulic power unit (HPU), failing at the ferrule. The technician, 20 metres (66 feet) away, safely shut off the HPU and isolated the pressure.

Original material courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/working-with-near-pressurised-systems-person-in-line-of-fire