-

What happened?

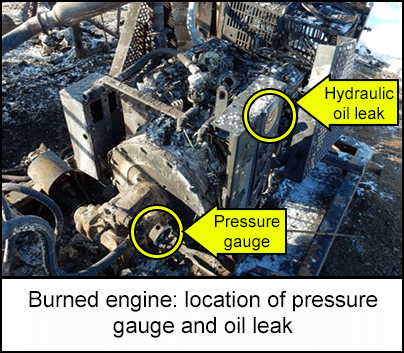

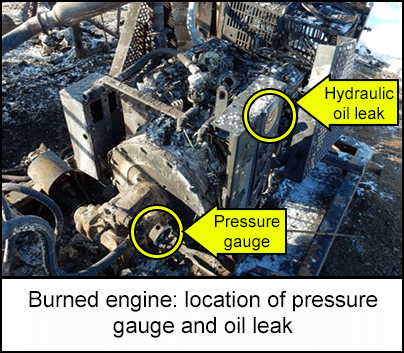

A crew was called out to a fire at a heavy oil well site when hydraulic oil leaked onto an engine exhaust manifold.

While no one was injured in the incident, the fire destroyed an engine skid, hydraulic system and associated equipment.

-

Why did it happen?

Following an analysis of the incident, it was determined the bourdon pressure gauge failed at the dial face and vent, causing hydraulic oil to leak onto the engine.

The gauge was not effectively isolated because of the piping configuration and the fire ignited from the engine’s exhaust manifold.

The gauge was under constant pressure in a high vibration/pulsation and high temperature environment. Over time, the bourdon tube of the pressure gauge failed.

-

What did they learn?

A pressure gauge and integrity review were completed across all operations, during which:

- All pressure gauges were checked for correct application, positioning, isolation and venting, as per manufacturers’ recommendations.

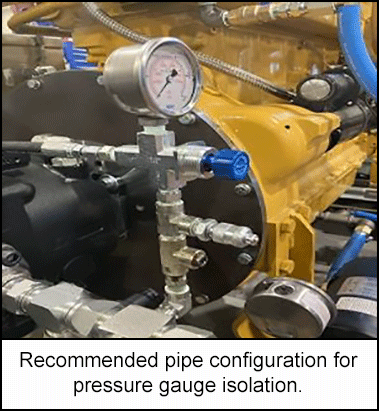

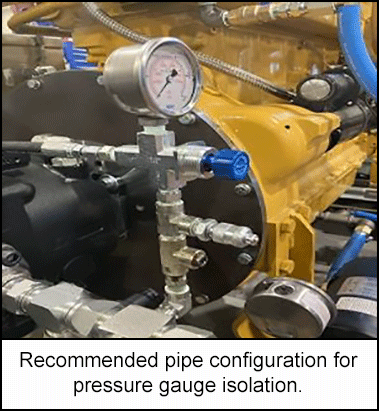

- All hydraulic systems on engine skids were fitted with a recommended pressure gauge isolation piping design.

-

Ask yourself or your crew

How can we prevent something like this from happening here?

What are other risks are associated with forklift operations? How can you mitigate those risks at your work site?

What safety recommendations should be included in the operational instructions?

How can we, as a company, implement a practical training plan that focuses on the job position, and make sure pedestrians are safer from forklifts in the future?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A crew was called out to a fire at a heavy oil well site when hydraulic oil leaked onto an engine exhaust manifold.

While no one was injured in the incident, the fire destroyed an engine skid, hydraulic system and associated equipment.

Why did it happen?

Following an analysis of the incident, it was determined the bourdon pressure gauge failed at the dial face and vent, causing hydraulic oil to leak onto the engine.

The gauge was not effectively isolated because of the piping configuration and the fire ignited from the engine’s exhaust manifold.

The gauge was under constant pressure in a high vibration/pulsation and high temperature environment. Over time, the bourdon tube of the pressure gauge failed.

What did they learn?

A pressure gauge and integrity review were completed across all operations, during which:

- All pressure gauges were checked for correct application, positioning, isolation and venting, as per manufacturers’ recommendations.

- All hydraulic systems on engine skids were fitted with a recommended pressure gauge isolation piping design.

Ask yourself or your crew

How can we prevent something like this from happening here?

What are other risks are associated with forklift operations? How can you mitigate those risks at your work site?

What safety recommendations should be included in the operational instructions?

How can we, as a company, implement a practical training plan that focuses on the job position, and make sure pedestrians are safer from forklifts in the future?

A crew was called out to a fire at a heavy oil well site when hydraulic oil leaked onto an engine exhaust manifold. While no one was injured in the incident, the fire destroyed an engine skid, hydraulic system and associated equipment.

Original material courtesy of Energy Safety Canada

Other resources:

Barrier Focused Approach

Walk the Line

Fire & Explosion Hazards Guide