-

What happened?

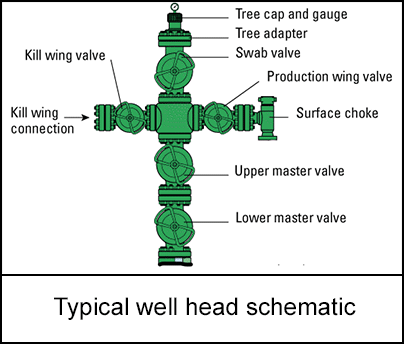

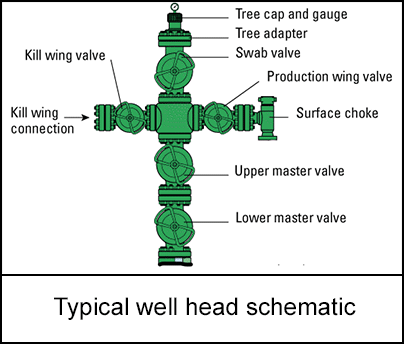

During a wellbore service in the winter months, a high-pressure gas release occurred.

The work plan included pumping down the kill line when the downhole operations were completed.

The kill line valves appeared in the closed direction, and no movement was found. This, along with the valve handles being absent, led the workers to believe the valves were closed.

The kill line was pressure tested and a valve began to leak. Operations were shut down to change the valve at which point an uncontrolled pressure release occurred.

The investigation revealed that the valves had been stuck open by ice. No workers were injured.

-

Why did it happen?

- Wellhead valves were left in operating position.

- Valves were not fully functioned and adequately oriented prior to pressure test.

- Sub-zero temperatures resulted in ice plugging the wellhead valves.

-

What did they learn?

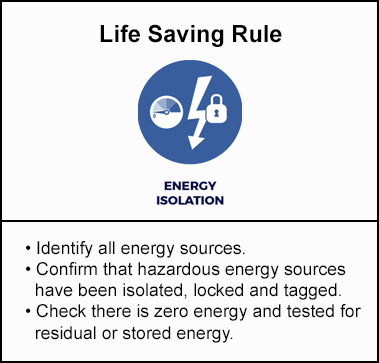

- Prior to conducting work, the wellhead’s unique structure and condition should be reviewed including the isolation procedure, valve orientation, and ensure positive confirmation of isolation.

- The work authorization process (e.g. safe work permit) must include on-site hazard assessment, hand over documentation and verification.

- Safe Operating Procedures should be reviewed before each task and include evaluation of on-site hazards, such as weather impacts like ice, valve and wellhead status and clearly outline responsibilities of workers and supervisors.

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

If you want to add this app to home screen tap and then ‘Add to Home Screen’.

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During a wellbore service in the winter months, a high-pressure gas release occurred.

The work plan included pumping down the kill line when the downhole operations were completed.

The kill line valves appeared in the closed direction, and no movement was found. This, along with the valve handles being absent, led the workers to believe the valves were closed.

The kill line was pressure tested and a valve began to leak. Operations were shut down to change the valve at which point an uncontrolled pressure release occurred.

The investigation revealed that the valves had been stuck open by ice. No workers were injured.

Why did it happen?

- Wellhead valves were left in operating position.

- Valves were not fully functioned and adequately oriented prior to pressure test.

- Sub-zero temperatures resulted in ice plugging the wellhead valves.

What did they learn?

- Prior to conducting work, the wellhead’s unique structure and condition should be reviewed including the isolation procedure, valve orientation, and ensure positive confirmation of isolation.

- The work authorization process (e.g. safe work permit) must include on-site hazard assessment, hand over documentation and verification.

- Safe Operating Procedures should be reviewed before each task and include evaluation of on-site hazards, such as weather impacts like ice, valve and wellhead status and clearly outline responsibilities of workers and supervisors.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Published on 28/04/23

1917 Views

During a wellbore service, a high-pressure gas release occurred. The work plan included pumping down the kill line and the kill line valves appeared to be closed, with no movement found. The kill line was pressure tested and a valve began to leak. Operations were shut down to change the valve at which point an uncontrolled pressure release occurred. The investigation revealed that the valves had been stuck open by ice.

Original material courtesy of Energy Safety Canada

Other external resources:

Microlearning | Energy isolation - video

DACC IRP Vol 5 Minimum Wellhead Requirements

Process Safety Maintaining Isolation Poster