-

What happened?

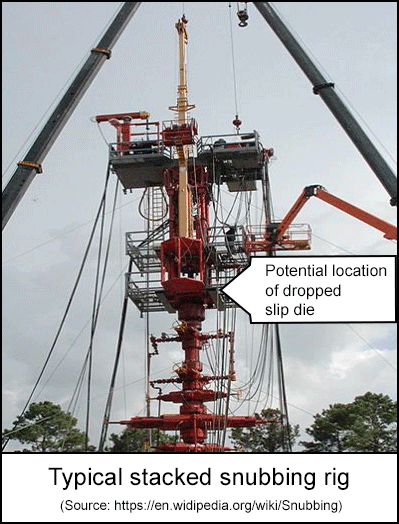

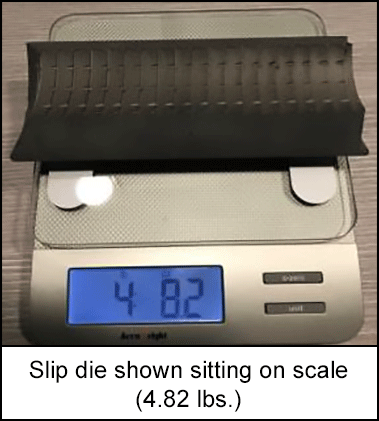

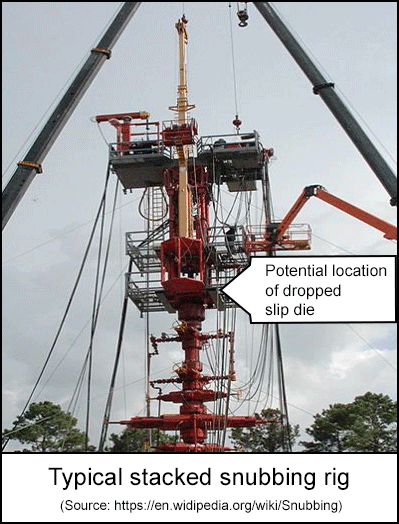

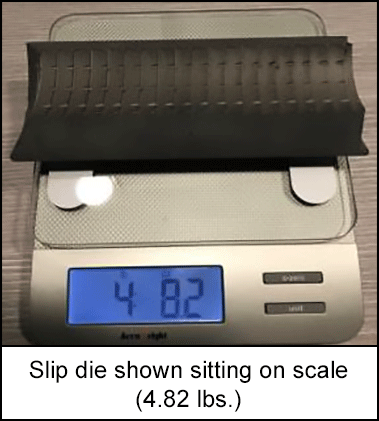

During a pre-move inspection of a stacked snubbing rig, an unsecured slip die weighing 2.05 kg (4.82 lbs.), fell approximately 21 m (70 ft) landing onto the ground 2 m (6 ft) from workers.

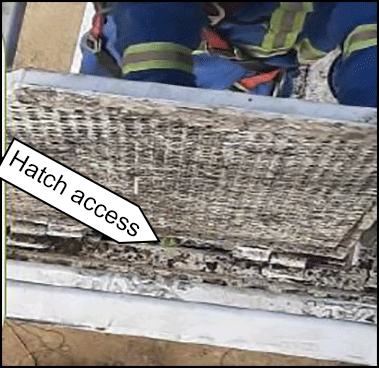

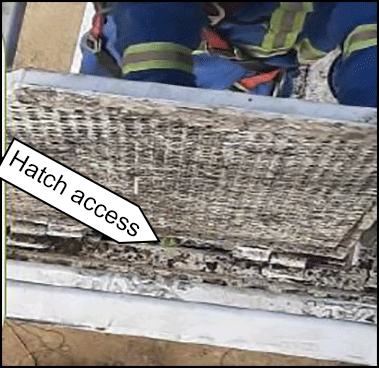

The slip die had been left behind and was lying on an access hatch. The slip die fell when the hatch was opened and could have severely or fatally injured workers on the ground.

-

Why did it happen?

When a worker inspected the rig prior to moving, the action of opening the access hatch caused the slip die (that was on the hatch floor) to slip through the hinged opening and onto the ground. A worker on the ground was nearly hit by the falling slip die, it landed approximately 2 m away from the worker.

Contributing Factors:

- The slip dies were previously removed to ready the rig for a move, however one remained on the floor of an access area.

- Misunderstanding of the exclusion zone requirements and distractions due to multiple changes in work scope.

- Inadequate dropped object prevention training.

-

What did they learn?

- According to the DROPSonline.org calculator, the potential consequence of this dropped object impacting a worker would have resulted in a fatality.

- The exclusion zone was not well-established, and workers were too close to the rig.

Corrective actions taken:

- The company held safety stand down to discuss managing scope changes and conflicting priorities.

- The company implemented formal DROPS training for workers and supervisors.

Did You Know? In Alberta (Canada), dropped objects comprise 29% of all potential serious injuries reported since June 1, 2018.

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During a pre-move inspection of a stacked snubbing rig, an unsecured slip die weighing 2.05 kg (4.82 lbs.), fell approximately 21 m (70 ft) landing onto the ground 2 m (6 ft) from workers.

The slip die had been left behind and was lying on an access hatch. The slip die fell when the hatch was opened and could have severely or fatally injured workers on the ground.

Why did it happen?

When a worker inspected the rig prior to moving, the action of opening the access hatch caused the slip die (that was on the hatch floor) to slip through the hinged opening and onto the ground. A worker on the ground was nearly hit by the falling slip die, it landed approximately 2 m away from the worker.

Contributing Factors:

- The slip dies were previously removed to ready the rig for a move, however one remained on the floor of an access area.

- Misunderstanding of the exclusion zone requirements and distractions due to multiple changes in work scope.

- Inadequate dropped object prevention training.

What did they learn?

- According to the DROPSonline.org calculator, the potential consequence of this dropped object impacting a worker would have resulted in a fatality.

- The exclusion zone was not well-established, and workers were too close to the rig.

Corrective actions taken:

- The company held safety stand down to discuss managing scope changes and conflicting priorities.

- The company implemented formal DROPS training for workers and supervisors.

Did You Know? In Alberta (Canada), dropped objects comprise 29% of all potential serious injuries reported since June 1, 2018.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

During a pre-move inspection of a stacked snubbing rig, an unsecured slip die weighing 2.05 kg (4.82 lbs.) fell approximately 21 metres (70 feet), landing 2 metres (6 feet) away from workers. This could have severely or fatally injured workers on the ground.

Original material courtesy of Energy Safety Canada

Learn more about this Life Saving Rule - Line of Fire