-

What happened?

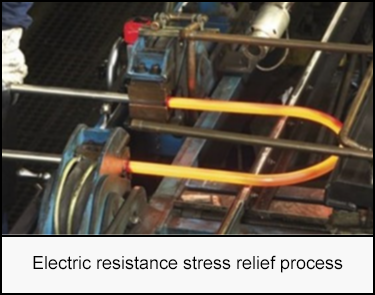

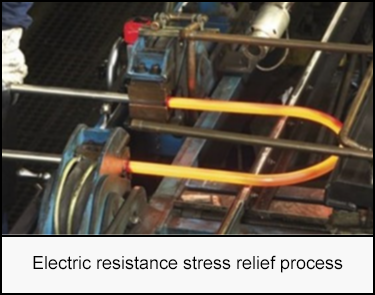

A sub-supplier provided over 1,300 tubes to a heat exchanger manufacturer without performing the required U-bend heat treatment, which relieves stress from cold bending. Without it, residual stresses can lead to corrosion, embrittlement, or cracking. Per Operator requirements, all tubes must be heat treated unless made from 400-series stainless steel, Hastelloy, or Inconel 625—unless otherwise specified.

Although heat treatment was correctly noted on the drawings, the tube manufacturer missed it during their internal 3-point check. The heat exchanger manufacturer’s receiving department and the third-party inspector also failed to verify the treatment, overlooking the absence of discoloration typical of heat-treated U-bends.

The issue was discovered after two bundles were assembled and all tubes had been strength welded.

-

Why did it happen?

Operator quality assurance continues to identify recurring issues with tube manufacturers and other sub-suppliers failing to meet requirements:

- 2020: Tube supplier did not anneal the tubes properly leading to cracked tubes during operations.

- 2024: Heat exchanger manufacturer failed to inspect incoming tube bundles that had not been annealed, risking startup delays and production loss.

- Multiple incidents: Non-conformances including incorrect weld rods, missing pre-heat for 1.25% chromium, and wrong plate thickness.

The current quality process relies on heat exchanger manufacturers to verify sub-supplier compliance, but repeated failures show this is ineffective. Due to the nature of the tube manufacturing process, stress relieving cannot be completed out of sequence, which can result in rework and schedule and cost impact.

-

What did they learn?

Additional quality oversight by operators is recommended at sub-supplier facilities when U-bend heat treatment is required. Inspection and test plans should include:

- Hold point at the tube manufacturer for high-criticality or complex heat exchangers so operator can verify U-bend heat treatment.

- Witness point at the tube manufacturer for low-criticality or simpler exchangers so operator can verify U-bend heat treatment.

- Review point at the heat exchanger manufacturer’s receiving department so operator can validate heat treatment.

Operator quality management personnel and project engineers should inform third-party inspectors of this requirement. Inspectors should verify U-bend heat treatment through a minimum of visual checks (e.g., discoloration) and review of documentation from both tube and heat exchanger manufacturers.

-

Ask yourself or your crew

How confident are we that our current quality assurance processes catch all critical manufacturing steps, such as U-bend heat treatment?

In what ways can we improve communication and clarity of technical requirements with sub-suppliers and third-party inspectors?

What risks are we taking by relying on others (e.g., heat exchanger manufacturers) to verify sub-supplier compliance, and how can we better manage those risks?

How do we determine when to apply hold, witness, or review points in our inspection plans, and are we applying them consistently based on risk and complexity?

What early warning signs or quality indicators could help us detect non-conformances before they impact schedule or cost? Have we seen similar quality issues with other equipment (if so, what)?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A sub-supplier provided over 1,300 tubes to a heat exchanger manufacturer without performing the required U-bend heat treatment, which relieves stress from cold bending. Without it, residual stresses can lead to corrosion, embrittlement, or cracking. Per Operator requirements, all tubes must be heat treated unless made from 400-series stainless steel, Hastelloy, or Inconel 625—unless otherwise specified.

Although heat treatment was correctly noted on the drawings, the tube manufacturer missed it during their internal 3-point check. The heat exchanger manufacturer’s receiving department and the third-party inspector also failed to verify the treatment, overlooking the absence of discoloration typical of heat-treated U-bends.

The issue was discovered after two bundles were assembled and all tubes had been strength welded.

Why did it happen?

Operator quality assurance continues to identify recurring issues with tube manufacturers and other sub-suppliers failing to meet requirements:

- 2020: Tube supplier did not anneal the tubes properly leading to cracked tubes during operations.

- 2024: Heat exchanger manufacturer failed to inspect incoming tube bundles that had not been annealed, risking startup delays and production loss.

- Multiple incidents: Non-conformances including incorrect weld rods, missing pre-heat for 1.25% chromium, and wrong plate thickness.

The current quality process relies on heat exchanger manufacturers to verify sub-supplier compliance, but repeated failures show this is ineffective. Due to the nature of the tube manufacturing process, stress relieving cannot be completed out of sequence, which can result in rework and schedule and cost impact.

What did they learn?

Additional quality oversight by operators is recommended at sub-supplier facilities when U-bend heat treatment is required. Inspection and test plans should include:

- Hold point at the tube manufacturer for high-criticality or complex heat exchangers so operator can verify U-bend heat treatment.

- Witness point at the tube manufacturer for low-criticality or simpler exchangers so operator can verify U-bend heat treatment.

- Review point at the heat exchanger manufacturer’s receiving department so operator can validate heat treatment.

Operator quality management personnel and project engineers should inform third-party inspectors of this requirement. Inspectors should verify U-bend heat treatment through a minimum of visual checks (e.g., discoloration) and review of documentation from both tube and heat exchanger manufacturers.

Ask yourself or your crew

How confident are we that our current quality assurance processes catch all critical manufacturing steps, such as U-bend heat treatment?

In what ways can we improve communication and clarity of technical requirements with sub-suppliers and third-party inspectors?

What risks are we taking by relying on others (e.g., heat exchanger manufacturers) to verify sub-supplier compliance, and how can we better manage those risks?

How do we determine when to apply hold, witness, or review points in our inspection plans, and are we applying them consistently based on risk and complexity?

What early warning signs or quality indicators could help us detect non-conformances before they impact schedule or cost? Have we seen similar quality issues with other equipment (if so, what)?

A tube manufacturer, a sub-supplier, have supplied more than 1,300 tubes to a heat exchanger manufacturer without performing the required U-bend heat treatment.