-

What happened?

In recent years, the industry has consistently faced a significant challenge: incidents related to socketed guardrail base failures, specifically where the guardrail sits in the socket.

These failures have not only resulted in severe injuries but have also tragically claimed lives.

This issue highlights the critical need for enhanced safety measures and rigorous inspection protocols to prevent such occurrences and ensure the well-being of all personnel.

-

Why did it happen?

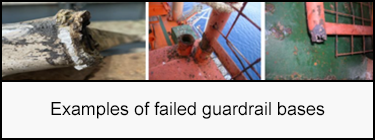

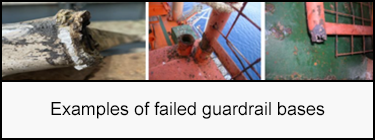

The guardrail base that sits in the socket is the highest stress area of the guardrail and is also where degradation most often occurs.

Failures were found to be from corrosion, mechanical fatigue, lack of drain holes (saltwater electrolyte), inadequate repairs, ageing infrastructure, water freezing and pushing base out of socket, and failure to re-install pins.

These degradation mechanisms are usually not visible unless the guardrail is removed for inspection. They have also been found to be painted over.

Generic ‘checklist’ inspections were also found to be potential error traps.

-

What did they learn?

Sites with socketed guardrails are encouraged to consider implementing the following safeguards:

Effective safeguards

- Visual inspection - confirm pins, drain holes, and brace bars/attachments to adjacent guardrails (for removable guardrails) are in good condition and in place. Provide pictures and details of what to look for in the work order/inspection checklist.

- Detailed inspection - require periodic removal of the guardrail for visual and hammer or other non-destructive testing of the guardrail base.

- Inspection frequency - as the site decides appropriate, considering site-specific conditions (e.g., in offshore more corrosive environments).

Less effective safeguards

- Generic inspection checklists – ensure enough detail/pictures/examples are provided.

- Management of change (MOC) - sometimes not applied for these types of repairs.

- Repair and weld quality control – sometimes not used for this type of repair.

- Incident reporting – near misses involving guardrail systems are often entered as safety work orders. Sites are also encouraged to enter them into the incident database to enable for improved incident trending.

-

Ask yourself or your crew

- How confident are we in the effectiveness of our current guardrail inspection processes?

- What site-specific conditions (e.g., corrosion, weather) could increase the risk of guardrail base failure here?

- Are we relying too heavily on generic checklists, and how could we make our inspections more targeted and visual?

- Have we ever missed or overlooked signs of degradation due to paint or lack of removal during inspection?

- What steps can we take to ensure near misses involving guardrails are properly reported and trended?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

In recent years, the industry has consistently faced a significant challenge: incidents related to socketed guardrail base failures, specifically where the guardrail sits in the socket.

These failures have not only resulted in severe injuries but have also tragically claimed lives.

This issue highlights the critical need for enhanced safety measures and rigorous inspection protocols to prevent such occurrences and ensure the well-being of all personnel.

Why did it happen?

The guardrail base that sits in the socket is the highest stress area of the guardrail and is also where degradation most often occurs.

Failures were found to be from corrosion, mechanical fatigue, lack of drain holes (saltwater electrolyte), inadequate repairs, ageing infrastructure, water freezing and pushing base out of socket, and failure to re-install pins.

These degradation mechanisms are usually not visible unless the guardrail is removed for inspection. They have also been found to be painted over.

Generic ‘checklist’ inspections were also found to be potential error traps.

What did they learn?

Sites with socketed guardrails are encouraged to consider implementing the following safeguards:

Effective safeguards

- Visual inspection - confirm pins, drain holes, and brace bars/attachments to adjacent guardrails (for removable guardrails) are in good condition and in place. Provide pictures and details of what to look for in the work order/inspection checklist.

- Detailed inspection - require periodic removal of the guardrail for visual and hammer or other non-destructive testing of the guardrail base.

- Inspection frequency - as the site decides appropriate, considering site-specific conditions (e.g., in offshore more corrosive environments).

Less effective safeguards

- Generic inspection checklists – ensure enough detail/pictures/examples are provided.

- Management of change (MOC) - sometimes not applied for these types of repairs.

- Repair and weld quality control – sometimes not used for this type of repair.

- Incident reporting – near misses involving guardrail systems are often entered as safety work orders. Sites are also encouraged to enter them into the incident database to enable for improved incident trending.

Ask yourself or your crew

- How confident are we in the effectiveness of our current guardrail inspection processes?

- What site-specific conditions (e.g., corrosion, weather) could increase the risk of guardrail base failure here?

- Are we relying too heavily on generic checklists, and how could we make our inspections more targeted and visual?

- Have we ever missed or overlooked signs of degradation due to paint or lack of removal during inspection?

- What steps can we take to ensure near misses involving guardrails are properly reported and trended?

A significant challenge in the industry is incidents related to socketed guardrail base failures, specifically where the guardrail sits in the socket. These have resulted in severe injuries and deaths.