-

What happened?

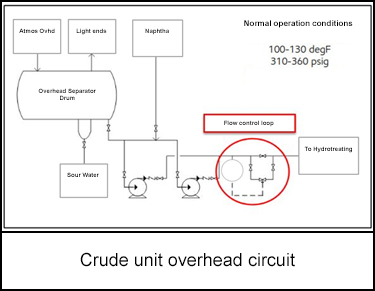

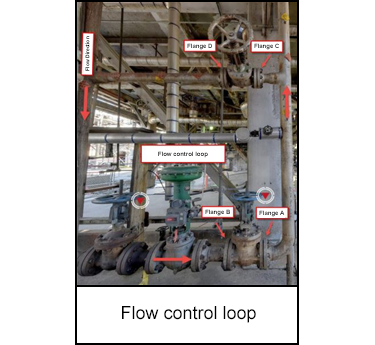

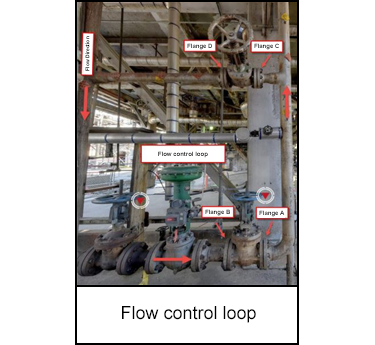

A small flange leak started in a control loop of crude unit overhead system (Flange A).

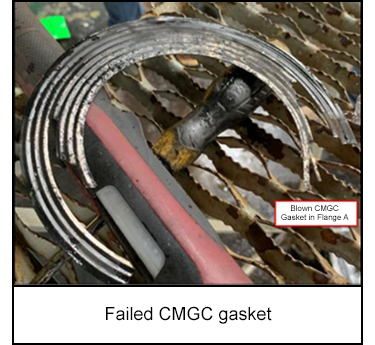

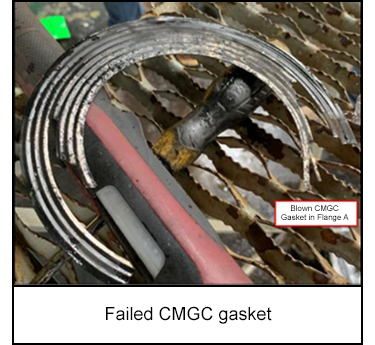

The corrugated metal graphite covered (CMGC) gasket completely failed within a short period of time (< 15 minutes).

Released light naphtha ignited, resulting in Tier 1 process safety event (PSE).

-

Why did it happen?

The gasket completely failed after the initial leak due to vibration and graphite delamination

- 4” (10cm) 300lb (136kg) flange class piping circuit

- Corrugated metal graphite covered (CMGC) gasket installed prior to 2000

- Small CMGC leaks can escalate to a large leak in a relatively short period of time

-

What did they learn?

Design limitations:

- Consider that CMGC gaskets are susceptible to graphite delamination

- Occurs when a small leak washes away graphite on either side of the corrugated metal

- Loss of graphite results in vibration, which leads to fatigue cracking

Previous implementation of lessons learned:

- In 2005, the Corporate piping material specification guidance was updated to require special approval for use of CMGC gaskets in CL300 piping systems, following several CMGC gasket failures (no retrofit required)

- Local site specifications allowed use of CMGC gaskets in CL300 piping systems, prior to adopting the Corporate specification in 2005

- In 2008, the Corporate global practice updated to require special approval to use CMGC gaskets in CL300 or higher piping flange classes

- General approach was to replace CMGC gaskets in CL300 piping systems when connection was opened (i.e. no need to retroactively replace)

- Consider that CMGC gaskets are susceptible to graphite delamination

-

Ask yourself or your crew

When was your site program (e.g. local pipe specs) last checked to ensure that no new CMGC gaskets are being installed in class 300 or higher service?

What are the potential risks / consequences (e.g. failure) of CMGC gaskets in class 300 or higher service, and are your site operations and mechanical teams aware of them?

- Note: If a CMGC gasket in class 300 or higher service is found during a maintenance activity then this gasket should be replaced with an approved alternative in practices

How do your site processes for flange leak mitigation adequately incorporate the increased risk for scenario escalation when/if CMGC CL300+ is involved (i.e. a small CMGC leak may escalate to a large leak, with the potential for complete failure, in a relatively short period of time)?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A small flange leak started in a control loop of crude unit overhead system (Flange A).

The corrugated metal graphite covered (CMGC) gasket completely failed within a short period of time (< 15 minutes).

Released light naphtha ignited, resulting in Tier 1 process safety event (PSE).

Why did it happen?

The gasket completely failed after the initial leak due to vibration and graphite delamination

- 4” (10cm) 300lb (136kg) flange class piping circuit

- Corrugated metal graphite covered (CMGC) gasket installed prior to 2000

- Small CMGC leaks can escalate to a large leak in a relatively short period of time

What did they learn?

Design limitations:

- Consider that CMGC gaskets are susceptible to graphite delamination

- Occurs when a small leak washes away graphite on either side of the corrugated metal

- Loss of graphite results in vibration, which leads to fatigue cracking

Previous implementation of lessons learned:

- In 2005, the Corporate piping material specification guidance was updated to require special approval for use of CMGC gaskets in CL300 piping systems, following several CMGC gasket failures (no retrofit required)

- Local site specifications allowed use of CMGC gaskets in CL300 piping systems, prior to adopting the Corporate specification in 2005

- In 2008, the Corporate global practice updated to require special approval to use CMGC gaskets in CL300 or higher piping flange classes

- General approach was to replace CMGC gaskets in CL300 piping systems when connection was opened (i.e. no need to retroactively replace)

Ask yourself or your crew

When was your site program (e.g. local pipe specs) last checked to ensure that no new CMGC gaskets are being installed in class 300 or higher service?

What are the potential risks / consequences (e.g. failure) of CMGC gaskets in class 300 or higher service, and are your site operations and mechanical teams aware of them?

- Note: If a CMGC gasket in class 300 or higher service is found during a maintenance activity then this gasket should be replaced with an approved alternative in practices

How do your site processes for flange leak mitigation adequately incorporate the increased risk for scenario escalation when/if CMGC CL300+ is involved (i.e. a small CMGC leak may escalate to a large leak, with the potential for complete failure, in a relatively short period of time)?

A small leak developed in a 4” (10 cm) 300 lb (136 kg) flange within the crude unit overhead system, where a corrugated metal graphite covered (CMGC) gasket completely failed within 15 minutes due to vibration and graphite delamination. The resulting release of light naphtha ignited, escalating into a Tier 1 process safety event.