-

What happened?

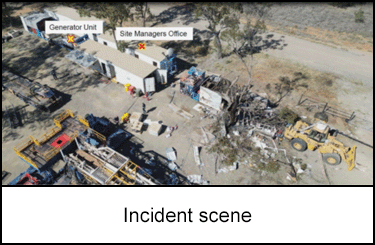

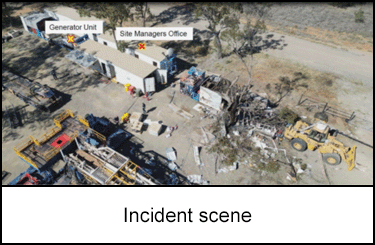

A rig manager arrived at a rig-site early in the morning and proceeded to switch on the generator for powering up the site. Approximately 15 minutes later there was an explosion in the tool house.

The blast shifted a loader forward 600mm (24 inches). Debris was found up to 100m (328 feet) away.

At the time of the operation the rig was not operational and undergoing maintenance. The rig manager was in the site manager’s office and was the only person on site.

The remaining crew were due to arrive later that morning. There were no injuries.

-

Why did it happen?

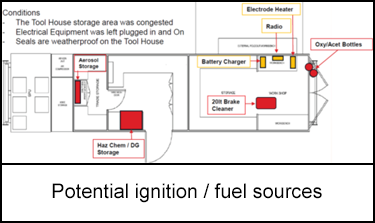

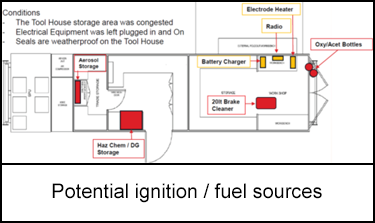

Fuel sources and combustibles in the tool house include oxy/acetylene bottles. Oxy/acetylene had been used the day prior to the incident. The regulator was attached to the bottle and the bottle had been left turned on (slightly). Post incident investigation revealed that the o-ring between the regulator and bottle on the acetylene cylinder was defective and leaking.

3 potential ignition sources were located approximately 1.2m (3.9 feet) from the oxy/acetylene bottles (welding rod electrode heater box; cordless tool battery charger; radio/stereo). These pieces of electrical equipment had been left plugged in and turned on. They became energised when the generator was switched on 15 minutes prior to the explosion.

The tool house is located on a 14m (46 feet) skid. The doors of the tool house are a shipping container style with airtight seals to prevent the intake of dust during transport. The doors were locked overnight to prevent theft (the rig site was close to town).

-

What did they learn?

Re-evaluate the need to have oxy/acetylene on-site as a regular piece of equipment.

Assess the risks associated with storage and transport of oxy/acetylene. Consider normal operations and also non-operational aspects, including transport, short term shutdowns (e.g. overnight shutdowns), and decommissioning phases (long term shutdowns).

Ensure that assurance activities include a review of the potential risks associated with explosive atmospheres beyond the operational and transport phases of operations where latent potential exists. Controls must be independent of the hazard (e.g. there cannot be a build-up of an explosive atmosphere).

Ensure any introduction of oxy/acetylene use is accompanied by a full management of change (MoC) process that considers both normal operations and non-operational aspects.

-

Ask yourself or your crew

Do you store or use oxy/acetylene at your site?

Do you know about explosion risks associated with oxy/acetylene?

Do have procedures for the safe storage and use of oxy/acetylene?

Could an explosive mix of oxy/acetylene occur on your site?

Do you have potential ignition sources near oxy/acetylene storage locations?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A rig manager arrived at a rig-site early in the morning and proceeded to switch on the generator for powering up the site. Approximately 15 minutes later there was an explosion in the tool house.

The blast shifted a loader forward 600mm (24 inches). Debris was found up to 100m (328 feet) away.

At the time of the operation the rig was not operational and undergoing maintenance. The rig manager was in the site manager’s office and was the only person on site.

The remaining crew were due to arrive later that morning. There were no injuries.

Why did it happen?

Fuel sources and combustibles in the tool house include oxy/acetylene bottles. Oxy/acetylene had been used the day prior to the incident. The regulator was attached to the bottle and the bottle had been left turned on (slightly). Post incident investigation revealed that the o-ring between the regulator and bottle on the acetylene cylinder was defective and leaking.

3 potential ignition sources were located approximately 1.2m (3.9 feet) from the oxy/acetylene bottles (welding rod electrode heater box; cordless tool battery charger; radio/stereo). These pieces of electrical equipment had been left plugged in and turned on. They became energised when the generator was switched on 15 minutes prior to the explosion.

The tool house is located on a 14m (46 feet) skid. The doors of the tool house are a shipping container style with airtight seals to prevent the intake of dust during transport. The doors were locked overnight to prevent theft (the rig site was close to town).

What did they learn?

Re-evaluate the need to have oxy/acetylene on-site as a regular piece of equipment.

Assess the risks associated with storage and transport of oxy/acetylene. Consider normal operations and also non-operational aspects, including transport, short term shutdowns (e.g. overnight shutdowns), and decommissioning phases (long term shutdowns).

Ensure that assurance activities include a review of the potential risks associated with explosive atmospheres beyond the operational and transport phases of operations where latent potential exists. Controls must be independent of the hazard (e.g. there cannot be a build-up of an explosive atmosphere).

Ensure any introduction of oxy/acetylene use is accompanied by a full management of change (MoC) process that considers both normal operations and non-operational aspects.

Ask yourself or your crew

Do you store or use oxy/acetylene at your site?

Do you know about explosion risks associated with oxy/acetylene?

Do have procedures for the safe storage and use of oxy/acetylene?

Could an explosive mix of oxy/acetylene occur on your site?

Do you have potential ignition sources near oxy/acetylene storage locations?

A rig manager switched on the generator at a rig-site undergoing maintenance, leading to an explosion in the tool house 15 minutes later. The blast caused significant debris spread and shifted a loader, but there were no injuries as the manager was the only person on site.

Original material courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/working-with-chemicals-explosion-leb-toolbox