-

What happened?

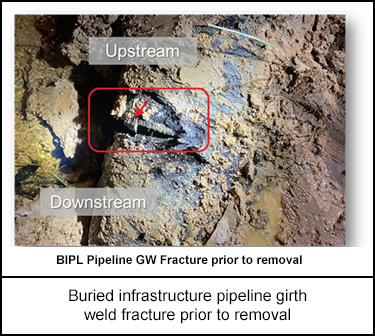

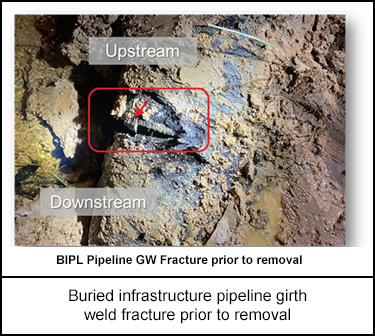

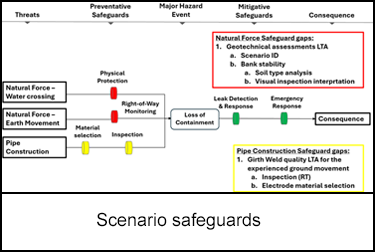

Gasoline was released from a 10” (25cm) pipeline. The girth weld failed due to forces exerted from earth movement.

The pipeline was in service since 1960 and was located near a water crossing and recreational park.

The pipeline monitoring system alerted operators of the leak, who initiated shutdown and emergency response.

No people or businesses were impacted.

-

Why did it happen?

Natural forces:

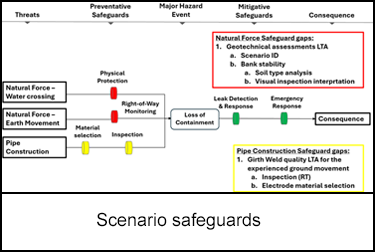

- Soil composition was identified as clay instead of silty sand

- Combination of soil composition (silt/sand) and flooding events made earth susceptible to movement; the scenario was not evaluated

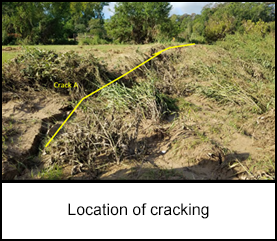

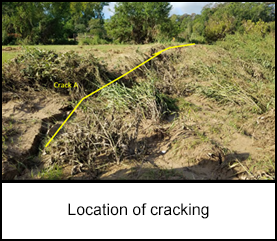

- Field observations (cracking, scarp, and bank erosion) created by water seepage from high water events were not recognised as indications of earth movement

Pipe construction:

- Failed girth weld not adequate to withstand earth movement; adequate for a stable bank, but insufficient to withstand the forces experienced

-

What did they learn?

Natural forces:

- Update tools and training materials to reinforce the effects of soil composition on potential earth movement risks

- Perform appropriate geotechnical analysis to assess risk

- Use field observations (ground cracks, scarp, erosion, etc.) in the pipeline right of way to trigger discussions with appropriate technical support staff regarding potential earth movement threat

- Integrate observations into comprehensive geotechnical assessments

Pipe construction:

- Ensure current standards are followed, requiring 100% Radiographic testing (RT) on all welds

-

Ask yourself or your crew

How can something like this happen here (e.g. on our site)?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

How do we know the risk controls/barriers are working?

What improvements or changes should we make to the procedures, controls/barriers, or the way we work?

Add to homescreen

If you want to add this app to home screen tap and then ‘Add to Home Screen’.

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Gasoline was released from a 10” (25cm) pipeline. The girth weld failed due to forces exerted from earth movement.

The pipeline was in service since 1960 and was located near a water crossing and recreational park.

The pipeline monitoring system alerted operators of the leak, who initiated shutdown and emergency response.

No people or businesses were impacted.

Why did it happen?

Natural forces:

- Soil composition was identified as clay instead of silty sand

- Combination of soil composition (silt/sand) and flooding events made earth susceptible to movement; the scenario was not evaluated

- Field observations (cracking, scarp, and bank erosion) created by water seepage from high water events were not recognised as indications of earth movement

Pipe construction:

- Failed girth weld not adequate to withstand earth movement; adequate for a stable bank, but insufficient to withstand the forces experienced

What did they learn?

Natural forces:

- Update tools and training materials to reinforce the effects of soil composition on potential earth movement risks

- Perform appropriate geotechnical analysis to assess risk

- Use field observations (ground cracks, scarp, erosion, etc.) in the pipeline right of way to trigger discussions with appropriate technical support staff regarding potential earth movement threat

- Integrate observations into comprehensive geotechnical assessments

Pipe construction:

- Ensure current standards are followed, requiring 100% Radiographic testing (RT) on all welds

Ask yourself or your crew

How can something like this happen here (e.g. on our site)?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

How do we know the risk controls/barriers are working?

What improvements or changes should we make to the procedures, controls/barriers, or the way we work?

Published on 22/05/25

938 Views

A gasoline leak occurred from a 10” (25cm) pipeline due to a girth weld failure caused by earth movement near a water crossing. The failure was linked to unrecognised soil instability and inadequate weld strength; no people or businesses were affected thanks to prompt detection and emergency response.