-

What happened?

After hours of use on site, black smoke and a flame began coming out of a boiler stack.

Systems were shut down and water was applied to the boiler cabinet.

-

Why did it happen?

Water was being heated but the boiler was not working efficiently, which led to a localized fire.

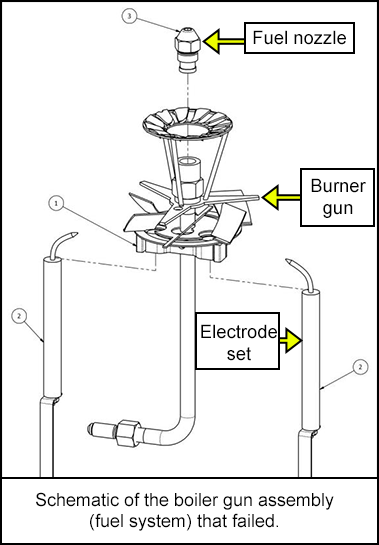

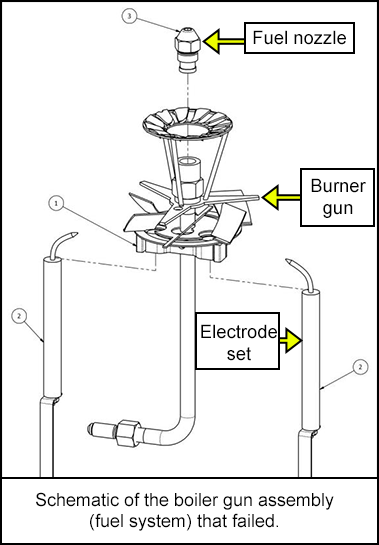

The systems electrode was not functioning effectively, some of the fuel was inadequately combusted and gathered within the fire box prior to its ignition. The ignition of this excess fuel resulted in a black smoke and visible flame.

Contributing factors:

Boiler cabinets are typically located in an insulated fire box to reduce potential damage caused by fire or inadequate combustion of diesel fuel. This containment reduced serious equipment damage and potentially further catastrophic event.

-

What did they learn?

Boilers are typically used during winter months and, after extended periods of inactivity, may require a full mechanical inspection. Additional preventative maintenance activities may include the replacement of in-line fuel filters, cleaning of poor fuel quality build-up, dirty, gummy or tacky components.

Corrective Actions:

- The worker noticed that the boiler was not running efficiently and at that time an excess flame was

observed. The equipment was manually shut down prior to activating the failsafe device. - The company determined that fuel quality or residual build up did not play a role in this incident.

- All systems including mobile equipment should be inspected any time it does not perform as

expected. - Workers should be trained in identifying potential issues and recognizing that prompt reporting to

management may prevent damage and potentially more severe incidents. - Reminder that any long-term inactivity of equipment may require additional adjustments prior to

use.

- The worker noticed that the boiler was not running efficiently and at that time an excess flame was

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

After hours of use on site, black smoke and a flame began coming out of a boiler stack.

Systems were shut down and water was applied to the boiler cabinet.

Why did it happen?

Water was being heated but the boiler was not working efficiently, which led to a localized fire.

The systems electrode was not functioning effectively, some of the fuel was inadequately combusted and gathered within the fire box prior to its ignition. The ignition of this excess fuel resulted in a black smoke and visible flame.

Contributing factors:

Boiler cabinets are typically located in an insulated fire box to reduce potential damage caused by fire or inadequate combustion of diesel fuel. This containment reduced serious equipment damage and potentially further catastrophic event.

What did they learn?

Boilers are typically used during winter months and, after extended periods of inactivity, may require a full mechanical inspection. Additional preventative maintenance activities may include the replacement of in-line fuel filters, cleaning of poor fuel quality build-up, dirty, gummy or tacky components.

Corrective Actions:

- The worker noticed that the boiler was not running efficiently and at that time an excess flame was

observed. The equipment was manually shut down prior to activating the failsafe device. - The company determined that fuel quality or residual build up did not play a role in this incident.

- All systems including mobile equipment should be inspected any time it does not perform as

expected. - Workers should be trained in identifying potential issues and recognizing that prompt reporting to

management may prevent damage and potentially more severe incidents. - Reminder that any long-term inactivity of equipment may require additional adjustments prior to

use.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

After hours of use on site, black smoke and a flame started coming out of a boiler stack. The water was being heated but the boiler was not working efficiently, which led to a localised fire.

Original material courtesy of Energy Safety Canada