-

What happened?

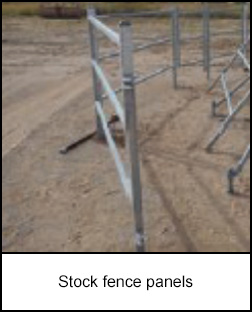

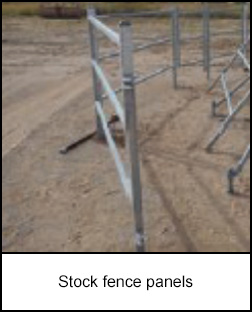

A workover rig crew was moving stock fence panels to clear a pathway for installing an 8-inch (20cm) flare line on the wellsite.

Two workers were in the process of shifting the panels.

The middle finger of one of the workers was pinched between two stock fence panels.

The finger tip was amputated.

The injured worker was wearing appropriate gloves at the time of the event.

-

Why did it happen?

The stock fence panels on the wellsite did not have stabilising feet. It had become common practice to move the stock fence panels while keeping them connected in a zig-zag pattern, to reduce the risk of them falling over when disconnected.

The action of pushing/pulling stock fence panels which remained connected (rather than disconnecting and moving the panels individually) increased the risk of hands being placed in the pinch zone.

-

What did they learn?

Discontinue using stock fence panels that do not have stabilising feet. When moving stock fence panels, disconnect them and move them individually.

Ensure that personal protective equipment (PPE), such as gloves, is adequate to prevent finger injuries.

Ensure that safety conversations and assessments adequately cover jobs that are considered incidental and routine.

-

Ask yourself or your crew

What types of stock fence panels are present at your worksite, and how do you ensure their stability and safety?

How do you approach the process of moving stock fence panels, and what factors influence your decision to disconnect them and move them individually?

How are ‘hands-free rules’ implemented at your site, and what specific tools or manual handling techniques are used to ensure safe operations?

How do you conduct safety conversations, and what impact do they have on your team's safety practices?

How do you assess and mitigate risks to hands and fingers during your safety discussions and task planning?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A workover rig crew was moving stock fence panels to clear a pathway for installing an 8-inch (20cm) flare line on the wellsite.

Two workers were in the process of shifting the panels.

The middle finger of one of the workers was pinched between two stock fence panels.

The finger tip was amputated.

The injured worker was wearing appropriate gloves at the time of the event.

Why did it happen?

The stock fence panels on the wellsite did not have stabilising feet. It had become common practice to move the stock fence panels while keeping them connected in a zig-zag pattern, to reduce the risk of them falling over when disconnected.

The action of pushing/pulling stock fence panels which remained connected (rather than disconnecting and moving the panels individually) increased the risk of hands being placed in the pinch zone.

What did they learn?

Discontinue using stock fence panels that do not have stabilising feet. When moving stock fence panels, disconnect them and move them individually.

Ensure that personal protective equipment (PPE), such as gloves, is adequate to prevent finger injuries.

Ensure that safety conversations and assessments adequately cover jobs that are considered incidental and routine.

Ask yourself or your crew

What types of stock fence panels are present at your worksite, and how do you ensure their stability and safety?

How do you approach the process of moving stock fence panels, and what factors influence your decision to disconnect them and move them individually?

How are ‘hands-free rules’ implemented at your site, and what specific tools or manual handling techniques are used to ensure safe operations?

How do you conduct safety conversations, and what impact do they have on your team's safety practices?

How do you assess and mitigate risks to hands and fingers during your safety discussions and task planning?

While shifting stock fence panels, the middle finger of a worker was pinched between two panels, amputating the finger. The injured worker was wearing appropriate gloves at the time of the event.

Original material courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/manual-handling-person-in-line-of-fire-leb-toolbox