-

What happened?

A crew performed a job safety analysis and completed several lifts safely with a 50T (110,231lbs) crane.

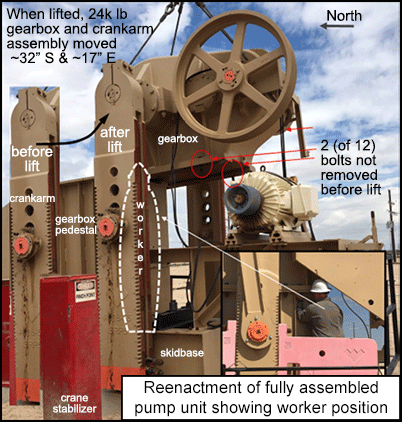

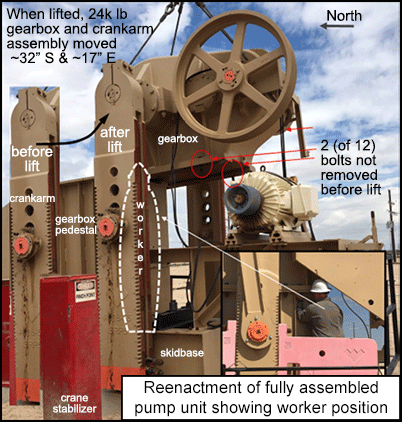

The crew then prepared to lift a 10,886kg (24,000 lbs) gearbox and crank arm assembly mounted on a pedestal. The crane boom was positioned off-center, the drive belts were not removed prior to the lift, and only 10 of 12 bolts were removed.

A worker stood next to the gearbox pedestal troubleshooting the two remaining bolts while in the crane operator’s direct line-of-sight, and instructed the field technician to retrieve the tagline in preparation for the lift.

The crane operator lifted the assembly, which rotated and crushed the worker against the gearbox pedestal. The worker died from their injuries.

-

Why did it happen?

The anchor bolts and drive belts were not removed prior to the lift, per procedure.

The boom was off-center, preventing a level lift.

Personnel were in the exclusion zone / line of fire.

The service company life saving rules requirements for lifting and rigging were not observed.

There was a lack of task planning, team coordination, and situational awareness.

-

What did they learn?

Confirm that workers involved in lifting and rigging can describe the life saving rules, and provide refresher training if needed.

Verify that higher risk activities (e.g. lifting and rigging) have appropriate supervisor oversight.

Perform task based assessments of lifting and rigging activities on a periodic basis to confirm effective execution of life saving rules requirements and procedural conformance.

-

Ask yourself or your crew

How can something like this happen here?

What are the rules for carrying out safe lifting operations?

Do we have any concerns about today’s lifting operation?

What factors can contribute to poor situational awareness?

How can we enhance communication between crew members during tasks?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A crew performed a job safety analysis and completed several lifts safely with a 50T (110,231lbs) crane.

The crew then prepared to lift a 10,886kg (24,000 lbs) gearbox and crank arm assembly mounted on a pedestal. The crane boom was positioned off-center, the drive belts were not removed prior to the lift, and only 10 of 12 bolts were removed.

A worker stood next to the gearbox pedestal troubleshooting the two remaining bolts while in the crane operator’s direct line-of-sight, and instructed the field technician to retrieve the tagline in preparation for the lift.

The crane operator lifted the assembly, which rotated and crushed the worker against the gearbox pedestal. The worker died from their injuries.

Why did it happen?

The anchor bolts and drive belts were not removed prior to the lift, per procedure.

The boom was off-center, preventing a level lift.

Personnel were in the exclusion zone / line of fire.

The service company life saving rules requirements for lifting and rigging were not observed.

There was a lack of task planning, team coordination, and situational awareness.

What did they learn?

Confirm that workers involved in lifting and rigging can describe the life saving rules, and provide refresher training if needed.

Verify that higher risk activities (e.g. lifting and rigging) have appropriate supervisor oversight.

Perform task based assessments of lifting and rigging activities on a periodic basis to confirm effective execution of life saving rules requirements and procedural conformance.

Ask yourself or your crew

How can something like this happen here?

What are the rules for carrying out safe lifting operations?

Do we have any concerns about today’s lifting operation?

What factors can contribute to poor situational awareness?

How can we enhance communication between crew members during tasks?

A gearbox and crank arm assembly mounted on a pedestal were being lifted by a crane. A worker stood next to the gearbox pedestal to troubleshoot two remaining bolts and the crane operator lifted the assembly. The crane boom was positioned off-center and the assembly rotated and fatally crushed the worker against the gearbox pedestal.