-

What happened?

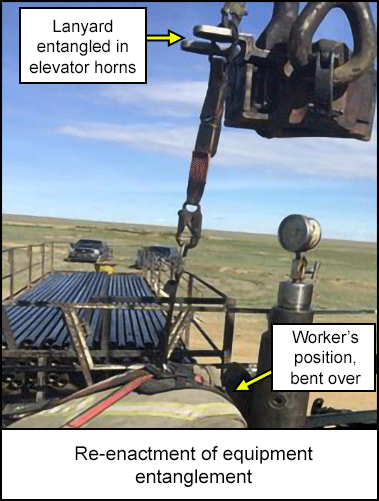

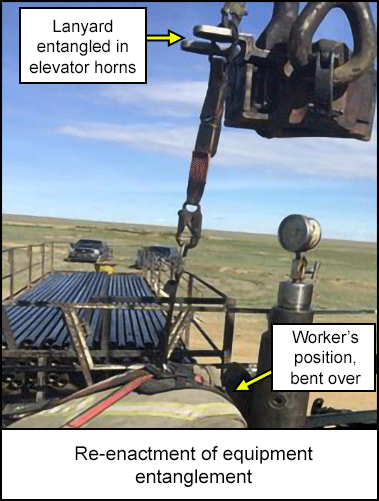

A worker’s fall protection equipment became entangled in hanging elevators.

The worker bent over to pick up a short joint of tubing, causing the D-ring on the shock absorbing lanyard to become snagged on the elevator horns.

The elevators were raised, and the entrapped worker was lifted off the work platform.

-

Why did it happen?

When the worker bent over to pick up a short piece of tubing, the vertical attachment line of the fall protection equipment whipped forward. The worker was not able to back away from the moving elevators quick enough, and the D-ring on the shock absorbing lanyard became entangled in the elevator horns. The elevator pulled the worker upwards off the tubing board. The elevator operator did not have line of sight with the worker.

Contributing factors:

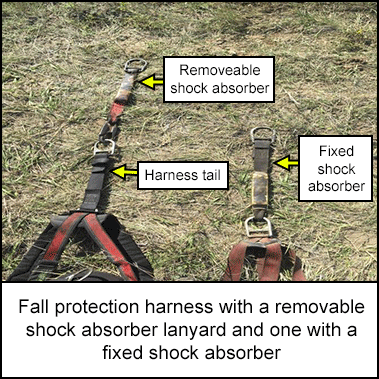

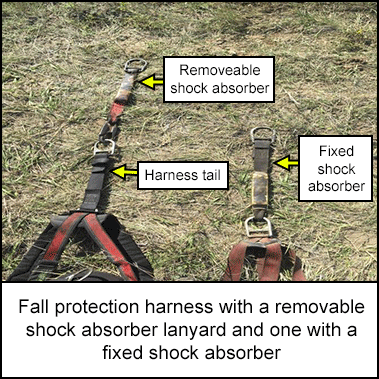

- The shock absorbing lanyard on the harness had a 12” extension, creating an additional hazard.

- The joint of tubing was approximately 1 m shorter than the rest of the tubing. This forced the worker to bend down in order to latch into the elevators, the worker’s fall protection equipment came in-line with elevators and the horn of the elevator snagged the lanyard’s D-ring.

-

What did they learn?

The task of picking up the shorter piece of tubing created a hazard for the worker.

The bent over position caused the vertical line of the fall protection equipment to whip forward as the elevator blocks travelled upward.

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A worker’s fall protection equipment became entangled in hanging elevators.

The worker bent over to pick up a short joint of tubing, causing the D-ring on the shock absorbing lanyard to become snagged on the elevator horns.

The elevators were raised, and the entrapped worker was lifted off the work platform.

Why did it happen?

When the worker bent over to pick up a short piece of tubing, the vertical attachment line of the fall protection equipment whipped forward. The worker was not able to back away from the moving elevators quick enough, and the D-ring on the shock absorbing lanyard became entangled in the elevator horns. The elevator pulled the worker upwards off the tubing board. The elevator operator did not have line of sight with the worker.

Contributing factors:

- The shock absorbing lanyard on the harness had a 12” extension, creating an additional hazard.

- The joint of tubing was approximately 1 m shorter than the rest of the tubing. This forced the worker to bend down in order to latch into the elevators, the worker’s fall protection equipment came in-line with elevators and the horn of the elevator snagged the lanyard’s D-ring.

What did they learn?

The task of picking up the shorter piece of tubing created a hazard for the worker.

The bent over position caused the vertical line of the fall protection equipment to whip forward as the elevator blocks travelled upward.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

A worker’s fall protection equipment became entangled after he bent over to pick up tubing. The shock absorbent lanyard became snagged on the elevator horns, allowing the entrapped worker to be lifted off the work platform when the elevators were raised.

Original material courtesy of Energy Safety Canada

Other resources:

Alberta OHS Fall Protection Plan

WorkSafeBC Introduction to Fall Protection