-

What happened?

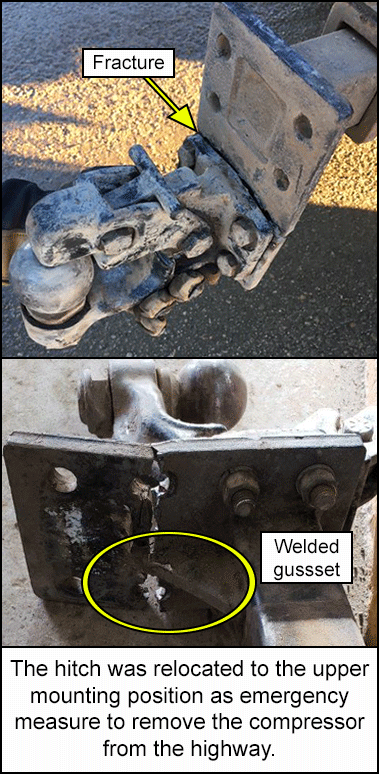

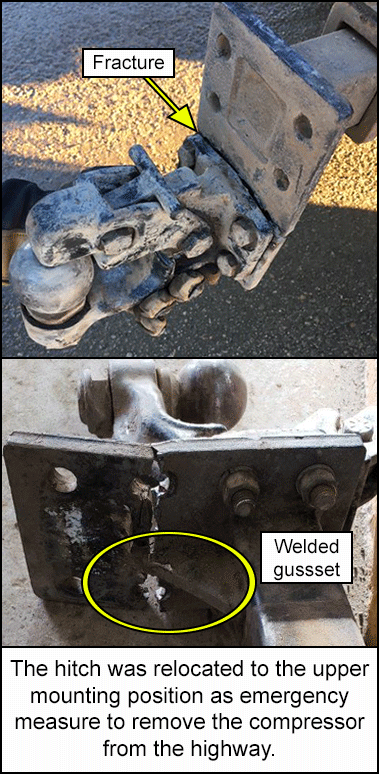

Workers departed a work site towing a portable air compressor. While driving on a major highway, the trailer fell to the ground behind the vehicle. The mounting plate on the pintle hitch had broken in half along the upper bolt holes.

The driver managed to bring the trailer under control and safely pulled over.

-

Why did it happen?

The welded gusset on back of the hitch mounting plate did not extend to the lower mounting holes which allowed the steel to flex and fracture.

Contributing factors:

- Inadequate towing equipment for the weight and type of equipment being towed.

- A thorough visual inspection was not performed during maintenance or pre-trip.

-

What did they learn?

The corrective actions identified by the company:

- The break-away safety restraint and the means of attaching it to the vehicle must have an ultimate strength of not less than the gross weight of the vehicle or trailer being towed.

- Inspect all hitches to ensure the gusset extends at least to the centre of the hitch on the lowest setting.

- Defective hitches and pintle mounts with cracks or concerning damage must be removed from service immediately.

-

Ask yourself or your crew

How can we prevent something like this from happening here?

What are other risks are associated with forklift operations? How can you mitigate those risks at your work site?

What safety recommendations should be included in the operational instructions?

How can we, as a company, implement a practical training plan that focuses on the job position, and make sure pedestrians are safer from forklifts in the future?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Workers departed a work site towing a portable air compressor. While driving on a major highway, the trailer fell to the ground behind the vehicle. The mounting plate on the pintle hitch had broken in half along the upper bolt holes.

The driver managed to bring the trailer under control and safely pulled over.

Why did it happen?

The welded gusset on back of the hitch mounting plate did not extend to the lower mounting holes which allowed the steel to flex and fracture.

Contributing factors:

- Inadequate towing equipment for the weight and type of equipment being towed.

- A thorough visual inspection was not performed during maintenance or pre-trip.

What did they learn?

The corrective actions identified by the company:

- The break-away safety restraint and the means of attaching it to the vehicle must have an ultimate strength of not less than the gross weight of the vehicle or trailer being towed.

- Inspect all hitches to ensure the gusset extends at least to the centre of the hitch on the lowest setting.

- Defective hitches and pintle mounts with cracks or concerning damage must be removed from service immediately.

Ask yourself or your crew

How can we prevent something like this from happening here?

What are other risks are associated with forklift operations? How can you mitigate those risks at your work site?

What safety recommendations should be included in the operational instructions?

How can we, as a company, implement a practical training plan that focuses on the job position, and make sure pedestrians are safer from forklifts in the future?

Workers departed a work site towing a portable air compressor. While driving on a major highway, the trailer fell to the ground behind the vehicle. The mounting plate on the pintle hitch had broken in half. The driver managed to bring the trailer under control and safely pulled over.

Original material courtesy of Energy Safety Canada