-

What happened?

A diving business was using an enriched air nitrox (EANx) compressor to produce Nitrox at 36% using the oxygen stick method.

Eight dive cylinders had been filled. When the ninth was being filled, an explosion and fireball occurred.

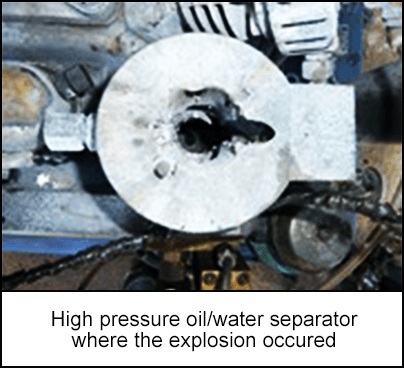

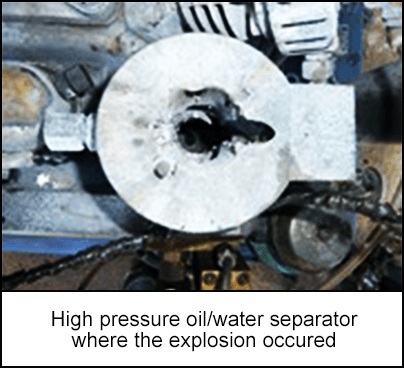

Parts of the oil/water separator were blown off the compressor. There was extensive damage to the compressor, surrounding structure, and parts of the neighbouring premises.

No one was injured, but there was a high risk of workers or others being killed or severely injured.

-

Why did it happen?

There was oil residue in the internal surfaces of the compressor unit, which in combination with oxygen and high temperatures can cause an explosion.

The compressor was second-hand and not approved for production of Nitrox.

Oxygen and other materials used are highly reactive once ignited.

-

What did they learn?

All operators using Nitrox compressors should be familiar with the hazards and safe use procedures.

The compression process can be affected by the type of compressor, the compatibility of the lubricants used, high oxygen concentration mixes above 23%, high operating temperatures, cleanliness of the parts of the system exposed to oxygen and the materials used in the manufacture of the equipment.

Ensure that all operating procedures are clearly documented and quality assured.

Only competent workers should install, operate, and maintain the compressors in line with manufacturer’s guidelines.

Ensure the compressor and decanting systems are located and operated away from public areas.

-

Ask yourself or your crew

How can something like this happen here?

What training do you need to work with the systems/gases involved here? What should you do if you don’t have the necessary training?

What checks should you complete before working with Nitrox compressors?

What risk factors are there with Nitrox production?

What measures do we have in place to prevent this from happening on our site? How can we improve?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A diving business was using an enriched air nitrox (EANx) compressor to produce Nitrox at 36% using the oxygen stick method.

Eight dive cylinders had been filled. When the ninth was being filled, an explosion and fireball occurred.

Parts of the oil/water separator were blown off the compressor. There was extensive damage to the compressor, surrounding structure, and parts of the neighbouring premises.

No one was injured, but there was a high risk of workers or others being killed or severely injured.

Why did it happen?

There was oil residue in the internal surfaces of the compressor unit, which in combination with oxygen and high temperatures can cause an explosion.

The compressor was second-hand and not approved for production of Nitrox.

Oxygen and other materials used are highly reactive once ignited.

What did they learn?

All operators using Nitrox compressors should be familiar with the hazards and safe use procedures.

The compression process can be affected by the type of compressor, the compatibility of the lubricants used, high oxygen concentration mixes above 23%, high operating temperatures, cleanliness of the parts of the system exposed to oxygen and the materials used in the manufacture of the equipment.

Ensure that all operating procedures are clearly documented and quality assured.

Only competent workers should install, operate, and maintain the compressors in line with manufacturer’s guidelines.

Ensure the compressor and decanting systems are located and operated away from public areas.

Ask yourself or your crew

How can something like this happen here?

What training do you need to work with the systems/gases involved here? What should you do if you don’t have the necessary training?

What checks should you complete before working with Nitrox compressors?

What risk factors are there with Nitrox production?

What measures do we have in place to prevent this from happening on our site? How can we improve?

A diving business was producing Nitrox at 36% using the oxygen stick method when an explosion and fireball occurred while a tank was being filled.