-

What happened?

A major shutdown for planned maintenance was initiated which involved depressurising the plant and flaring hydrocarbons.

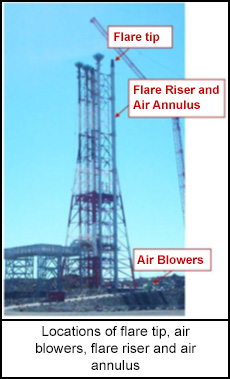

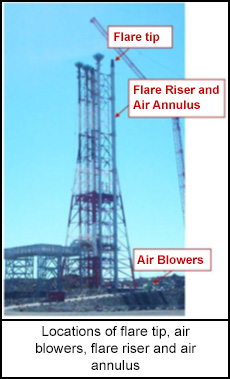

As part of shutdown work scopes, the main flare air blowers were taken offline leading to no positive pressure within the air annulus of the flare warm wet (FWW) and spare first stage flares.

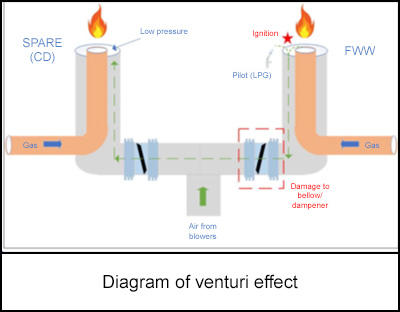

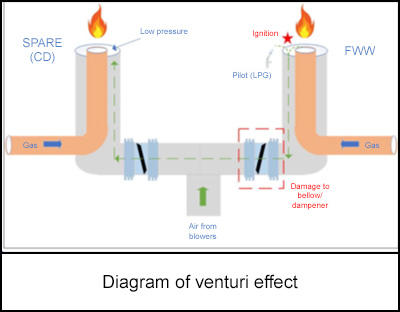

These two air assist flares were communicating through common air ducting and open dampers.

A venturi effect (created by a low-pressure point at the spare first stage tip) drew hydrocarbon from the flare warm wet gas riser/pilots into the air annulus towards the spare flare.

A flammable atmosphere was then created and ignited at the flare warm wet tip, leading to a deflagration (causing flare warm wet tip damage) followed by a detonation which caused the flare warm wet bellows to rupture.

-

Why did it happen?

The air assist system design was modified, and operating mode changed at different times before facility startup.

The risk of hydrocarbon ingress into the air assist system was not identified during design reviews.

As such, appropriate controls for this scenario were not identified.

The flare air assist design was novel to the industry at the time of design.

Lessons from a past incident that identified the risk of hydrocarbon ingress into a flare air assist annulus were not clearly articulated.

-

What did they learn?

Emergency Preparedness: Before the commencement of a task, familiarise yourself with primary and secondary muster points.

Risk identification: Vendor engagement during front-end design and safety reviews / HAZOP, is important, specifically for novel or complex systems.

Communication: Ensure that operating procedures provide key vendor parameters and a clear line of sight to operational risks.

-

Ask yourself or your crew

What makes certain areas of your facility novel to your company and the industry?

How do you ensure that your risk assessments are conducted with the right expertise to address potential risks?

Why is it important to know the primary and secondary muster points at your facility, and how do you ensure everyone is aware of them?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A major shutdown for planned maintenance was initiated which involved depressurising the plant and flaring hydrocarbons.

As part of shutdown work scopes, the main flare air blowers were taken offline leading to no positive pressure within the air annulus of the flare warm wet (FWW) and spare first stage flares.

These two air assist flares were communicating through common air ducting and open dampers.

A venturi effect (created by a low-pressure point at the spare first stage tip) drew hydrocarbon from the flare warm wet gas riser/pilots into the air annulus towards the spare flare.

A flammable atmosphere was then created and ignited at the flare warm wet tip, leading to a deflagration (causing flare warm wet tip damage) followed by a detonation which caused the flare warm wet bellows to rupture.

Why did it happen?

The air assist system design was modified, and operating mode changed at different times before facility startup.

The risk of hydrocarbon ingress into the air assist system was not identified during design reviews.

As such, appropriate controls for this scenario were not identified.

The flare air assist design was novel to the industry at the time of design.

Lessons from a past incident that identified the risk of hydrocarbon ingress into a flare air assist annulus were not clearly articulated.

What did they learn?

Emergency Preparedness: Before the commencement of a task, familiarise yourself with primary and secondary muster points.

Risk identification: Vendor engagement during front-end design and safety reviews / HAZOP, is important, specifically for novel or complex systems.

Communication: Ensure that operating procedures provide key vendor parameters and a clear line of sight to operational risks.

Ask yourself or your crew

What makes certain areas of your facility novel to your company and the industry?

How do you ensure that your risk assessments are conducted with the right expertise to address potential risks?

Why is it important to know the primary and secondary muster points at your facility, and how do you ensure everyone is aware of them?

During a major shutdown, a venturi effect (created by a low-pressure point at the spare first stage tip) drew hydrocarbon from the flare warm wet gas riser/pilots into the air annulus towards the spare flare. A flammable atmosphere was then created and ignited at the flare warm wet tip, leading to a deflagration (causing flare warm wet tip damage) followed by a detonation which caused the flare warm wet bellows to rupture.

Original material courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/maintaining-process-equipment-explosion-leb-toolbox