-

What happened?

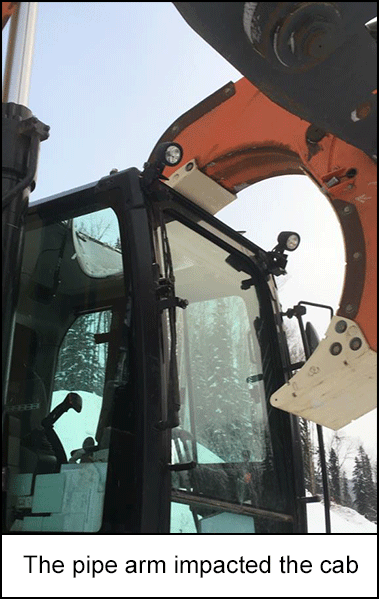

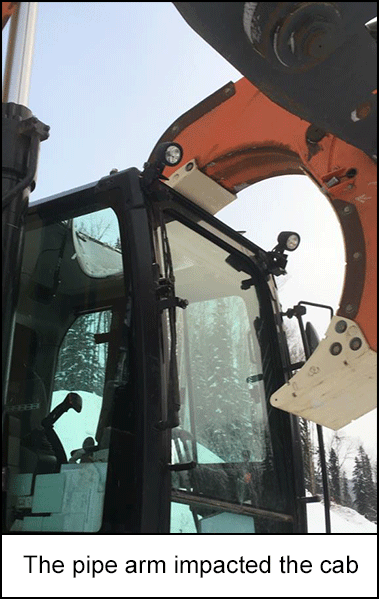

During extremely cold temperatures (-34 C), an excavator was damaged when the pipe arm

attachment impacted the cab.A mobile mechanic was required to get the excavator running, and it took 1.5 hours to start the equipment due to the extreme cold. The operator had let the excavator run for approximately 20 to 30 minutes, and then began the pre-use inspection and functionality test.

As the boom was lifted during part of the functionality test, the pipe arm attachment started curling inward on its own towards the cab of the excavator. It impacted the top of the excavator cab damaging the skylight, skylight latch and cracking the front windshield.

-

Why did it happen?

The hydraulic fluid in the excavator had thickened due to the drop in temperature, freezing the

components in the oil, which impacted the response of the pipe arm attachment.Contributing factors:

There was not enough warm-up time to allow for adequate fluid circulation in the extremely

cold weather conditions, and the operator did not engage the secondary engine shut-off

switch.

-

What did they learn?

- When ambient temperatures fall below -18 C, an extended warm-up/fluid circulation time should be implemented to compensate for potentially thickened fluids.

- The company has implemented an emergency engine shut down procedure.

- The manufacturer suggested that a pipe arm attachment should not be used in

temperatures below -30 C. - Check with manufacturer for appropriate fluids and temperature ratings

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During extremely cold temperatures (-34 C), an excavator was damaged when the pipe arm

attachment impacted the cab.

A mobile mechanic was required to get the excavator running, and it took 1.5 hours to start the equipment due to the extreme cold. The operator had let the excavator run for approximately 20 to 30 minutes, and then began the pre-use inspection and functionality test.

As the boom was lifted during part of the functionality test, the pipe arm attachment started curling inward on its own towards the cab of the excavator. It impacted the top of the excavator cab damaging the skylight, skylight latch and cracking the front windshield.

Why did it happen?

The hydraulic fluid in the excavator had thickened due to the drop in temperature, freezing the

components in the oil, which impacted the response of the pipe arm attachment.

Contributing factors:

There was not enough warm-up time to allow for adequate fluid circulation in the extremely

cold weather conditions, and the operator did not engage the secondary engine shut-off

switch.

What did they learn?

- When ambient temperatures fall below -18 C, an extended warm-up/fluid circulation time should be implemented to compensate for potentially thickened fluids.

- The company has implemented an emergency engine shut down procedure.

- The manufacturer suggested that a pipe arm attachment should not be used in

temperatures below -30 C. - Check with manufacturer for appropriate fluids and temperature ratings

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

A mechanic was required to get the excavator running which took longer to start due to the extreme cold. The mechanic let the excavator run for just under half an hour, and then began the pre-use inspection and functionality test. As the boom was lifted during the functionality test, the pipe arm attachment started curling inward on its own towards the cab of the excavator. It impacted the top of the excavator cab damaging the skylight, its latch and cracking the front windshield. Fortunately, the mechanic was not injured.

Original material courtesy of Energy Safety Canada