-

What happened?

Multiple high-potential incidents were reported due to trolleys falling from their runway beams. A few examples include:

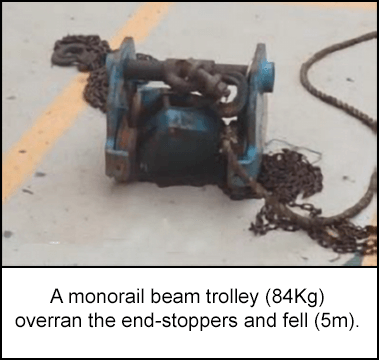

An 84 kg (185 lbs.) monorail beam trolley overran the end-stoppers and fell 5 meters (16 feet). Fortunately, no personnel were injured.

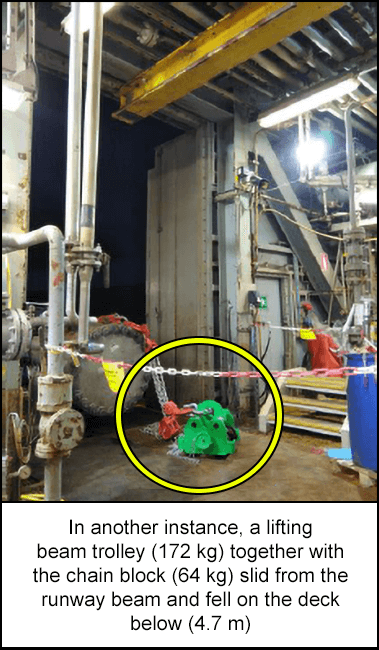

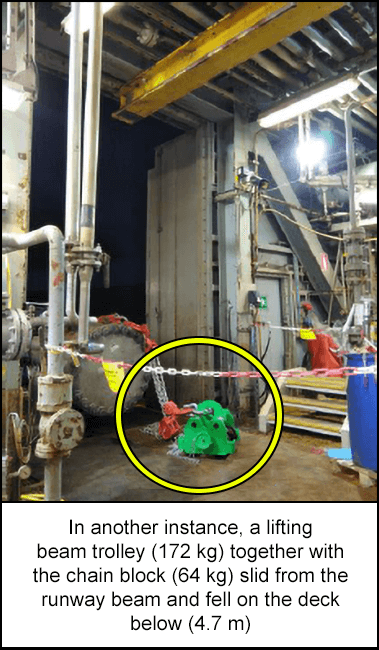

A 172 kg (379 lbs.) lifting beam trolley, along with a 64 kg (141 lbs.) chain block, slid from the runway beam and fell 4.7 meters (15.5 feet) onto the deck below. Thankfully, no injuries were recorded.

The outermost wheel mechanism of a trolley passed the stopper, and the trolley was found hanging off the end of the runway beam.

A 40 kg (88 lbs.) lifting beam trolley dropped from the end of the runway beam, falling 3 meters (10 feet) to the deck below.

All these incidents had the potential for fatality and damage to the lift equipment and/or the load.

-

Why did it happen?

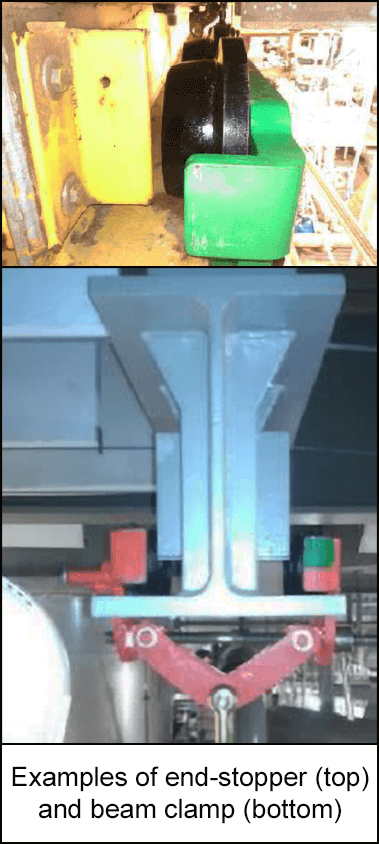

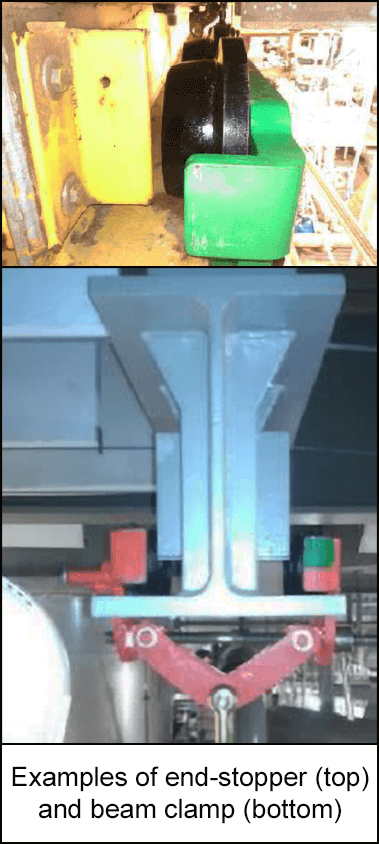

In all the cases exemplifies in the previous section, the runway beam end-stoppers failed to prevent the hoist trolleys running off the end of the beam.

The end-stoppers were either undersized for the beam/trolley width or the manual hoist trolleys were oversized for the beam used.

-

What did they learn?

Beam end stoppers are typically designed for specific types of trolleys, as outlined in the manufacturer's guide. However, if a different type of trolley is used, there is a risk that the end-stop may not be properly sized for the new trolley, potentially leading to safety issues.

Perform a survey of the runway beams to identify and address end-stoppers that do not extend to the edge of the beam and ensure they fit all types of trolleys.

Regularly inspect and certify the monorails on which the trolleys are installed.

Confirm that the trolley is fit for the beam and properly installed according to the manufacturer's instructions, checking the beam range markings.

Conduct a functional test, including end-stopper effectiveness, after each trolley installation, and include it in site procedures.

-

Ask yourself or your crew

How can something like this happen here (e.g. on our site)?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

How do we know the risk controls/barriers are working?

What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Multiple high-potential incidents were reported due to trolleys falling from their runway beams. A few examples include:

An 84 kg (185 lbs.) monorail beam trolley overran the end-stoppers and fell 5 meters (16 feet). Fortunately, no personnel were injured.

A 172 kg (379 lbs.) lifting beam trolley, along with a 64 kg (141 lbs.) chain block, slid from the runway beam and fell 4.7 meters (15.5 feet) onto the deck below. Thankfully, no injuries were recorded.

The outermost wheel mechanism of a trolley passed the stopper, and the trolley was found hanging off the end of the runway beam.

A 40 kg (88 lbs.) lifting beam trolley dropped from the end of the runway beam, falling 3 meters (10 feet) to the deck below.

All these incidents had the potential for fatality and damage to the lift equipment and/or the load.

Why did it happen?

In all the cases exemplifies in the previous section, the runway beam end-stoppers failed to prevent the hoist trolleys running off the end of the beam.

The end-stoppers were either undersized for the beam/trolley width or the manual hoist trolleys were oversized for the beam used.

What did they learn?

Beam end stoppers are typically designed for specific types of trolleys, as outlined in the manufacturer's guide. However, if a different type of trolley is used, there is a risk that the end-stop may not be properly sized for the new trolley, potentially leading to safety issues.

Perform a survey of the runway beams to identify and address end-stoppers that do not extend to the edge of the beam and ensure they fit all types of trolleys.

Regularly inspect and certify the monorails on which the trolleys are installed.

Confirm that the trolley is fit for the beam and properly installed according to the manufacturer's instructions, checking the beam range markings.

Conduct a functional test, including end-stopper effectiveness, after each trolley installation, and include it in site procedures.

Ask yourself or your crew

How can something like this happen here (e.g. on our site)?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

How do we know the risk controls/barriers are working?

What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Multiple high-potential incidents were reported due to trolleys falling from their runway beams. In all cases exemplified in this presentation, the runway beam end-stoppers failed to prevent the hoist trolleys running off the end of the beam. The end-stoppers were either undersized for the beam/trolley width or the manual hoist trolleys were oversized for the beam used.