-

What happened?

A short duration internal flash fire occurred in a spill container while unloading gasoline from a road tanker at a retail filling station.

The road tanker driver had three fuel compartments to unload: one diesel and two gasoline (95 octane grade).

After completing unloading one compartment of gasoline, the unloading hose was disconnected.

While the driver was closing the gasoline underground tank cam lock coupling located within the spill container, the flash fire occurred. The duration of a few seconds meant that road tanker driver did not need to use the adjacent fire extinguisher.

The unloading hose end melted. There was no other property damage, no loss of containment (incident escalation) and no personnel injury.

-

Why did it happen?

The immediate cause was attributed to static electricity ignition of a flammable atmosphere in the spill container.

It is reasonable to expect a flammable atmosphere and air in the spill container during disconnection of the unloading hose. Therefore, fire prevention (‘the fire triangle’) is achieved by controlling ignition sources.

The investigation identified static electricity as the likely ignition source. The following were considered the most credible means for the static electricity to accumulate:

- Personal protective equipment (PPE), possibly overalls but more likely gloves, were not sufficiently static dissipative.

- Isolation from earth of cam lock coupling (male) when handled using insulating gloves.

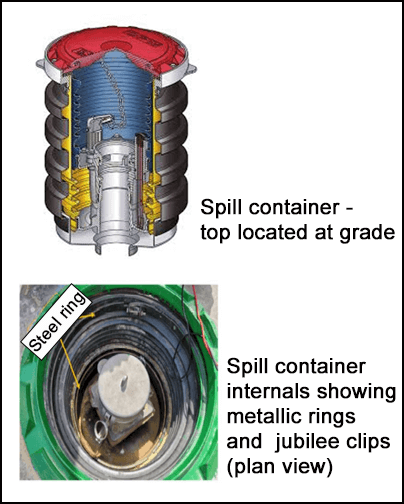

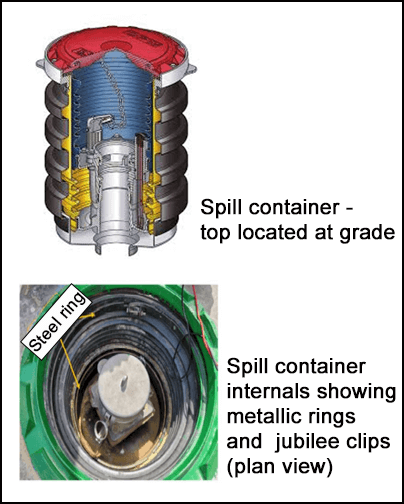

- Isolation from earth of spill containment holding ring and jubilee clips assembly.

The root causes were:

- Inadequate PPE

- Equipment design (electrical continuity of spill container materials).

- Procedures.

-

What did they learn?

Upgrade all older high-density polyethylene (HDPE) spill containment systems to the new stainless-steel equivalent and ensure all components are properly earthed and bonded, where necessary.

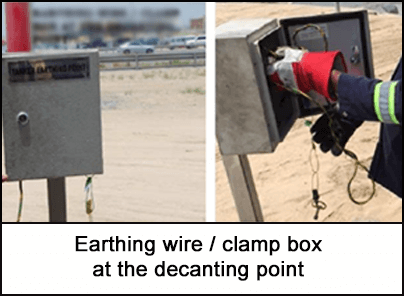

Connect spill containment cover and cam lock couplings to a permanent earthing wire.

Provide a permanent earthing wire for movable (male) cam lock coupling component to the bulk of the cam lock (which otherwise may form an insulating aluminium oxide layer).

Install a safety isolation valve on the decanting pipe within the spill container and train operators to close the valve before disconnecting the hose so as to exclude air inflow into the spill container, thus preventing accumulation of fuel vapour in the container space.

Operators should wear correctly specified static dissipative gloves and overalls.

After completing a delivery, allow static electricity to relax before dipping tanks (typically 15 minutes).

-

Ask yourself or your crew

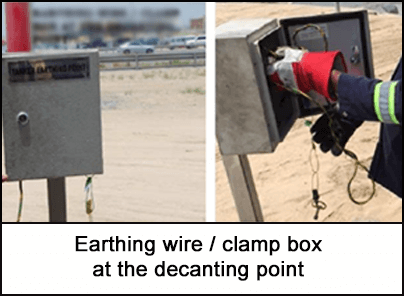

Do you know why earthing and bonding are required in procedures when unloading petroleum fuels from road tankers?

How do you know when earthing was last checked and what was the condition? What should you do if you notice a defective earthing wire or clamp on site equipment?

What should you do before starting to unload petroleum fuels from a road tanker a step in our procedure?

What would be your immediate action if you saw a fire during unloading of petroleum fuels from your road tanker?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A short duration internal flash fire occurred in a spill container while unloading gasoline from a road tanker at a retail filling station.

The road tanker driver had three fuel compartments to unload: one diesel and two gasoline (95 octane grade).

After completing unloading one compartment of gasoline, the unloading hose was disconnected.

While the driver was closing the gasoline underground tank cam lock coupling located within the spill container, the flash fire occurred. The duration of a few seconds meant that road tanker driver did not need to use the adjacent fire extinguisher.

The unloading hose end melted. There was no other property damage, no loss of containment (incident escalation) and no personnel injury.

Why did it happen?

The immediate cause was attributed to static electricity ignition of a flammable atmosphere in the spill container.

It is reasonable to expect a flammable atmosphere and air in the spill container during disconnection of the unloading hose. Therefore, fire prevention (‘the fire triangle’) is achieved by controlling ignition sources.

The investigation identified static electricity as the likely ignition source. The following were considered the most credible means for the static electricity to accumulate:

- Personal protective equipment (PPE), possibly overalls but more likely gloves, were not sufficiently static dissipative.

- Isolation from earth of cam lock coupling (male) when handled using insulating gloves.

- Isolation from earth of spill containment holding ring and jubilee clips assembly.

The root causes were:

- Inadequate PPE

- Equipment design (electrical continuity of spill container materials).

- Procedures.

What did they learn?

Upgrade all older high-density polyethylene (HDPE) spill containment systems to the new stainless-steel equivalent and ensure all components are properly earthed and bonded, where necessary.

Connect spill containment cover and cam lock couplings to a permanent earthing wire.

Provide a permanent earthing wire for movable (male) cam lock coupling component to the bulk of the cam lock (which otherwise may form an insulating aluminium oxide layer).

Install a safety isolation valve on the decanting pipe within the spill container and train operators to close the valve before disconnecting the hose so as to exclude air inflow into the spill container, thus preventing accumulation of fuel vapour in the container space.

Operators should wear correctly specified static dissipative gloves and overalls.

After completing a delivery, allow static electricity to relax before dipping tanks (typically 15 minutes).

Ask yourself or your crew

Do you know why earthing and bonding are required in procedures when unloading petroleum fuels from road tankers?

How do you know when earthing was last checked and what was the condition? What should you do if you notice a defective earthing wire or clamp on site equipment?

What should you do before starting to unload petroleum fuels from a road tanker a step in our procedure?

What would be your immediate action if you saw a fire during unloading of petroleum fuels from your road tanker?

A short duration internal flash fire occurred in a spill container while unloading gasoline from a road tanker at a retail filling station.