-

What happened?

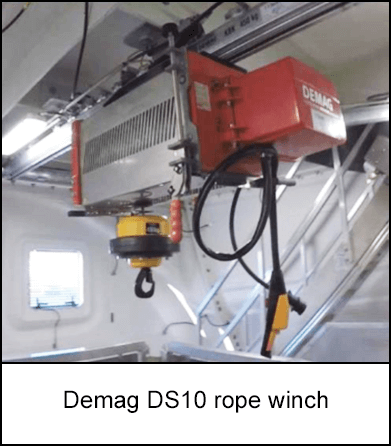

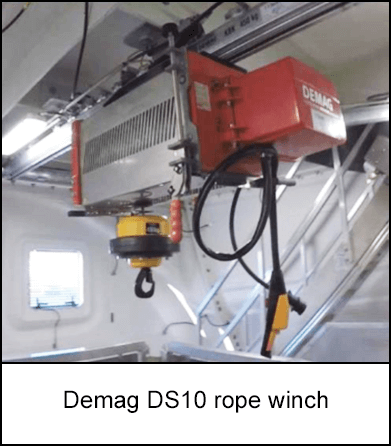

During a troubleshooting task, two technicians were lowering equipment from the nacelle to the transition piece (TP) entrance level using a Demag DS 10 crane. The crane had been used earlier in the day without any reported issues.

As they were lifting a large bag, it became entangled with the kickplate of the access gate on the crane hatch.

To free the bag, one technician operated the control pendant to lift it higher, while the other technician pushed the crane towards its parked position above the hatch. In this process, the technician pushing the crane received an electric shock on the right arm.

-

Why did it happen?

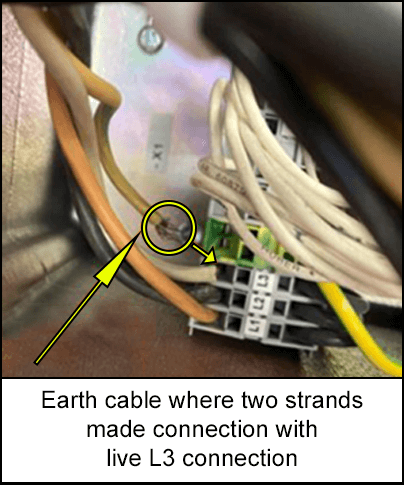

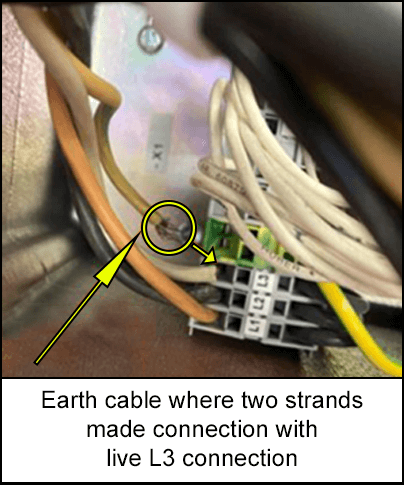

The loose earth cable contacts exposed a live L3 connection, leading to the electrification of the crane casing.

The improper installation of the supply cable by the contractor led to the earth conductor coming loose.

Human error played a role when the crane was operated outside of its designated parked position and when the proper wiring integrity checks were not conducted during the annual inspection (e.g. wiring integrity within the crane casing, verification of earth loop impedance checks on the equipment).

-

What did they learn?

Establish refresher training on the use of the Demag DS 10 crane to ensure operators understand the restrictions of crane operations until technical solutions can be implemented to eliminate this risk.

- For the affected sites, consider the following technical solution: Fit/install wire crimps/end sleeves to the 690v supply cable conductors for termination in the Demag DS10 crane.

- Include the wire sleeves and crimps as part of the annual inspection.

As a long-term solution, consider incorporating the following measures into the annual inspections:

- Implement verification for the electrical connection of the supply cable in the Demag DS10 switchbox to address the potential hazard of conductors becoming loose due to movement and vibrations.

- Include verification of earth loop impedance checks on equipment, such as the Demag DS10 Crane casing.

-

Ask yourself or your crew

What safety protocols and restrictions should operators be aware of while using the Demag DS 10 crane?

What actions should you take if you notice any abnormalities or issues during crane operations or inspections?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate risk during crane operations?

What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During a troubleshooting task, two technicians were lowering equipment from the nacelle to the transition piece (TP) entrance level using a Demag DS 10 crane. The crane had been used earlier in the day without any reported issues.

As they were lifting a large bag, it became entangled with the kickplate of the access gate on the crane hatch.

To free the bag, one technician operated the control pendant to lift it higher, while the other technician pushed the crane towards its parked position above the hatch. In this process, the technician pushing the crane received an electric shock on the right arm.

Why did it happen?

The loose earth cable contacts exposed a live L3 connection, leading to the electrification of the crane casing.

The improper installation of the supply cable by the contractor led to the earth conductor coming loose.

Human error played a role when the crane was operated outside of its designated parked position and when the proper wiring integrity checks were not conducted during the annual inspection (e.g. wiring integrity within the crane casing, verification of earth loop impedance checks on the equipment).

What did they learn?

Establish refresher training on the use of the Demag DS 10 crane to ensure operators understand the restrictions of crane operations until technical solutions can be implemented to eliminate this risk.

- For the affected sites, consider the following technical solution: Fit/install wire crimps/end sleeves to the 690v supply cable conductors for termination in the Demag DS10 crane.

- Include the wire sleeves and crimps as part of the annual inspection.

As a long-term solution, consider incorporating the following measures into the annual inspections:

- Implement verification for the electrical connection of the supply cable in the Demag DS10 switchbox to address the potential hazard of conductors becoming loose due to movement and vibrations.

- Include verification of earth loop impedance checks on equipment, such as the Demag DS10 Crane casing.

Ask yourself or your crew

What safety protocols and restrictions should operators be aware of while using the Demag DS 10 crane?

What actions should you take if you notice any abnormalities or issues during crane operations or inspections?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate risk during crane operations?

What improvements or changes should we make to the procedures, controls/barriers or the way we work?

During a troubleshooting task, two technicians were lowering equipment from the nacelle to the transition piece (TP) entrance level using a Demag DS 10 crane. During the process, one of the technicians received an electric shock on the right arm.