-

What happened?

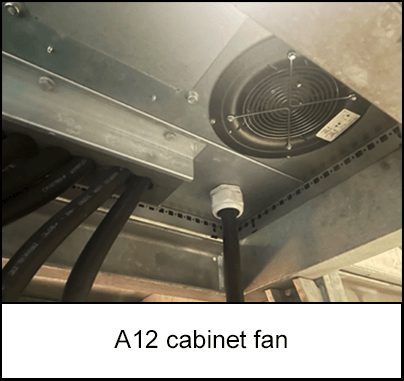

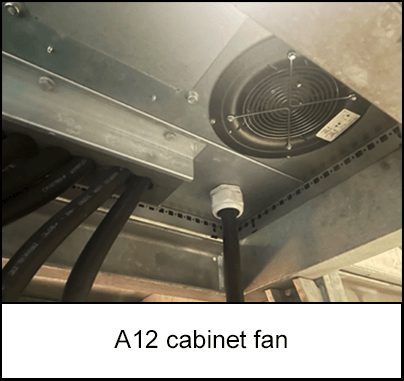

Two workers were assigned a work order (WO) to change the connection of a converter fan during a service task.

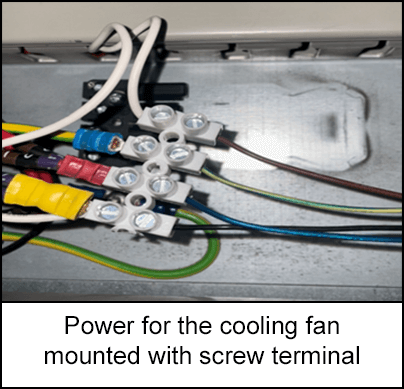

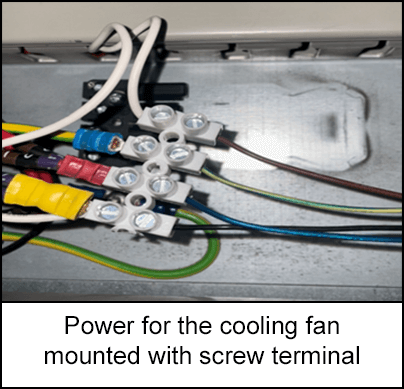

The fan had previously been connected to a screw terminal instead of its original plug, and the WO aimed to revert it back to the plug connection.

Unfortunately, the WO lacked the necessary documentation to ensure safety from the system, and the correct electrical schematic drawing was not found.

Despite the absence of documentation and the wrong point of isolation being used, the work continued.

While disassembling the fan, one worker faced the challenge of the wires being too short to find a suitable storage location. In an attempt to move a hand toward the terminal screws without using any personal protective equipment (PPE) gloves, the worker received an electrical shock when their finger touched a live wire.

The incident resulted in visible marks on his skin at the wrist and finger.

-

Why did it happen?

There was a gap between the official processes and the actual way of operating on-site.

The lack of documentation, including risk assessment and method statement (RAMS), work instructions (WI), and isolation documents, further increased the risk.

The worker was not wearing personal protective equipment (PPE) gloves.

The emergency response plan (ERP) was not followed correctly, and an individual was not medically examined until four days after the incident.

Furthermore, the isolation procedure for securing zero energy during an emergency was incorrect in the ERP, posing a potential risk to first aiders in the event of a rescue.

The incident revealed problems with the incident management software user profile on the device used. The profile was not properly configured, and as a result, relevant individuals were not adequately notified through the case management system.

-

What did they learn?

Adopt a culture of using documentation instead of relying solely on memory for isolation procedures. This will enhance safety measures within the system.

Improve the communication of relevant processes for all sites to ensure a clear understanding among all personnel.

Conduct training sessions on wind turbine generators (WTG) for both supervisors and employees to enhance their knowledge and skills.

Regularly perform audits on the safe system of work (SSW) for electrical tasks on all assets to maintain safety standards.

-

Ask yourself or your crew

Can you recall an incident involving electrical tasks where the documentation provided was insufficient or unclear? How did you address the situation?

How often do you encounter situations where the actual work processes differ from the established procedures? How can we address this effectively?

Are you confident in your understanding of the correct isolation procedures during emergencies? If not, what areas would you like more training on?

What measures can we implement to enhance communication about safety processes and protocols within our team?

In your experience, how often are audits conducted on safe systems of work for electrical tasks? Do you believe more frequent audits would be beneficial? Why or why not?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Two workers were assigned a work order (WO) to change the connection of a converter fan during a service task.

The fan had previously been connected to a screw terminal instead of its original plug, and the WO aimed to revert it back to the plug connection.

Unfortunately, the WO lacked the necessary documentation to ensure safety from the system, and the correct electrical schematic drawing was not found.

Despite the absence of documentation and the wrong point of isolation being used, the work continued.

While disassembling the fan, one worker faced the challenge of the wires being too short to find a suitable storage location. In an attempt to move a hand toward the terminal screws without using any personal protective equipment (PPE) gloves, the worker received an electrical shock when their finger touched a live wire.

The incident resulted in visible marks on his skin at the wrist and finger.

Why did it happen?

There was a gap between the official processes and the actual way of operating on-site.

The lack of documentation, including risk assessment and method statement (RAMS), work instructions (WI), and isolation documents, further increased the risk.

The worker was not wearing personal protective equipment (PPE) gloves.

The emergency response plan (ERP) was not followed correctly, and an individual was not medically examined until four days after the incident.

Furthermore, the isolation procedure for securing zero energy during an emergency was incorrect in the ERP, posing a potential risk to first aiders in the event of a rescue.

The incident revealed problems with the incident management software user profile on the device used. The profile was not properly configured, and as a result, relevant individuals were not adequately notified through the case management system.

What did they learn?

Adopt a culture of using documentation instead of relying solely on memory for isolation procedures. This will enhance safety measures within the system.

Improve the communication of relevant processes for all sites to ensure a clear understanding among all personnel.

Conduct training sessions on wind turbine generators (WTG) for both supervisors and employees to enhance their knowledge and skills.

Regularly perform audits on the safe system of work (SSW) for electrical tasks on all assets to maintain safety standards.

Ask yourself or your crew

Can you recall an incident involving electrical tasks where the documentation provided was insufficient or unclear? How did you address the situation?

How often do you encounter situations where the actual work processes differ from the established procedures? How can we address this effectively?

Are you confident in your understanding of the correct isolation procedures during emergencies? If not, what areas would you like more training on?

What measures can we implement to enhance communication about safety processes and protocols within our team?

In your experience, how often are audits conducted on safe systems of work for electrical tasks? Do you believe more frequent audits would be beneficial? Why or why not?

Two workers were assigned a work order (WO) to change the connection of a converter fan during a service task. Unfortunately, the WO lacked the necessary documentation to ensure safety from the system, and the correct electrical schematic drawing was not found. Despite the absence of documentation and the wrong point of isolation being used, the work continued. One of the workers was injured after touching a live wire.