-

What happened?

Two maintenance workers were removing water hoses used during recent hydraulic fracturing operations.

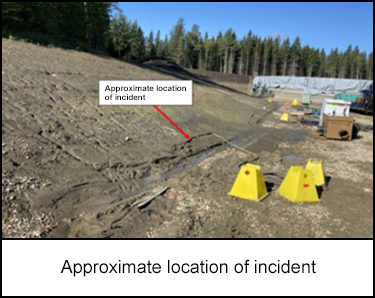

While working along the south side of the site, one worker noticed an electrical power cable was installed on top of the water hose. Concerned it might get pulled during removal, the worker paused and reached down to move the cable.

Upon touching it, they felt a tingling sensation, likely an electric shock, and quickly let go.

The incident was reported to the supervisor, and the power was shut off. A medic evaluated the worker, who showed no immediate injury but was advised to seek further medical attention.

-

Why did it happen?

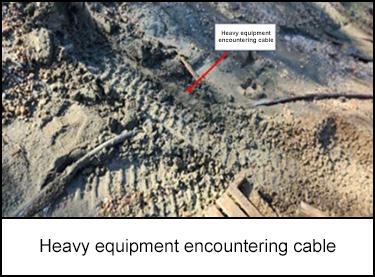

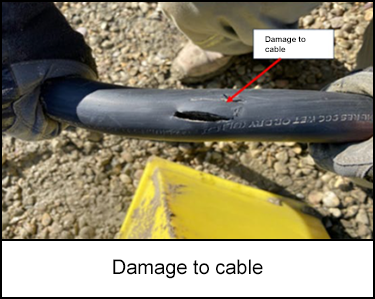

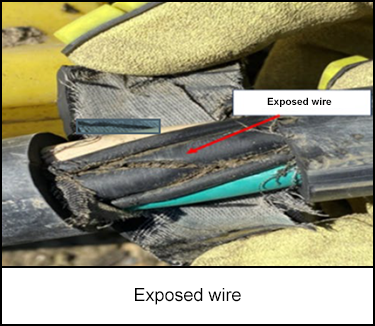

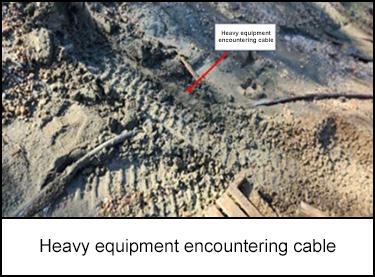

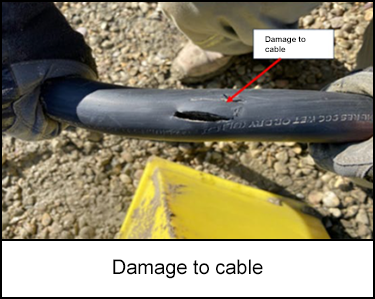

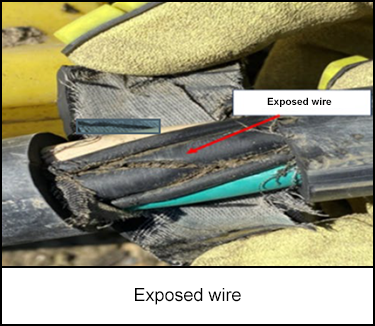

Immediate Cause: The electrical cable was damaged by heavy equipment, and lying unprotected across a water hose.

Underlying Causes:

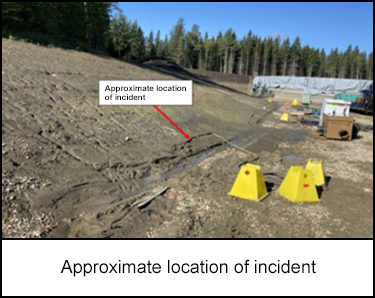

- Poor site layout and lack of barriers to separate electrical cables from heavy equipment movement.

- Area was thought to be a non-traffic area, so temporary cable installations were not clearly marked or protected. However, site storage location and snow removal required equipment movement in the incident area. Original plan was different from the executed plan.

-

What did they learn?

- Site Setup and Maintenance

- Temporary electrical cables must be clearly marked, protected, and separated from work areas and equipment routes.

- Site layout should reflect actual use, including storage and snow removal zones, to avoid unintentional traffic through hazardous areas.

- Hazard Identification and Planning

- Involve qualified electrical personnel during planning to assess risks, define safe distances, and establish exclusion zones.

- Conduct thorough hazard assessments that consider temporary installations and evolving site conditions.

- Controls and Safeguards

- Use physical barriers and clear signage to prevent contact with electrical cables.

- Apply Simultaneous operations (SIMOPS) planning to coordinate overlapping tasks safely.

- Enforce Stop work authority (SWA) to empower workers to halt unsafe operations.

- Ensure job safety plans and briefings are aligned with electrical safety standards and local regulations.

- Perform regular electrical inspections to detect and correct faults early.

- Implement change-of-scope planning to reassess hazards when work conditions change.

- Design and Documentation

- Align site execution with the original design, or document and communicate any deviations.

- Submit incidents like this to industry bodies (e.g., Energy Institute Toolbox) to support shared learning.

- Site Setup and Maintenance

-

Ask yourself or your crew

- Are any temporary electrical cables exposed or unprotected in our work area?

- Have we involved a qualified electrical person in our site planning?

- Do we know the location of all energised cables or buried utilities?

- Is our job safety plan aligned with electrical safety standards?

- What barriers or markings are in place to prevent accidental contact with power cables?

- If you saw a cable lying across your work path, would you know whether it’s safe to move?

Add to homescreen

If you want to add this app to home screen tap and then ‘Add to Home Screen’.

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Two maintenance workers were removing water hoses used during recent hydraulic fracturing operations.

While working along the south side of the site, one worker noticed an electrical power cable was installed on top of the water hose. Concerned it might get pulled during removal, the worker paused and reached down to move the cable.

Upon touching it, they felt a tingling sensation, likely an electric shock, and quickly let go.

The incident was reported to the supervisor, and the power was shut off. A medic evaluated the worker, who showed no immediate injury but was advised to seek further medical attention.

Why did it happen?

Immediate Cause: The electrical cable was damaged by heavy equipment, and lying unprotected across a water hose.

Underlying Causes:

- Poor site layout and lack of barriers to separate electrical cables from heavy equipment movement.

- Area was thought to be a non-traffic area, so temporary cable installations were not clearly marked or protected. However, site storage location and snow removal required equipment movement in the incident area. Original plan was different from the executed plan.

What did they learn?

- Site Setup and Maintenance

- Temporary electrical cables must be clearly marked, protected, and separated from work areas and equipment routes.

- Site layout should reflect actual use, including storage and snow removal zones, to avoid unintentional traffic through hazardous areas.

- Hazard Identification and Planning

- Involve qualified electrical personnel during planning to assess risks, define safe distances, and establish exclusion zones.

- Conduct thorough hazard assessments that consider temporary installations and evolving site conditions.

- Controls and Safeguards

- Use physical barriers and clear signage to prevent contact with electrical cables.

- Apply Simultaneous operations (SIMOPS) planning to coordinate overlapping tasks safely.

- Enforce Stop work authority (SWA) to empower workers to halt unsafe operations.

- Ensure job safety plans and briefings are aligned with electrical safety standards and local regulations.

- Perform regular electrical inspections to detect and correct faults early.

- Implement change-of-scope planning to reassess hazards when work conditions change.

- Design and Documentation

- Align site execution with the original design, or document and communicate any deviations.

- Submit incidents like this to industry bodies (e.g., Energy Institute Toolbox) to support shared learning.

Ask yourself or your crew

- Are any temporary electrical cables exposed or unprotected in our work area?

- Have we involved a qualified electrical person in our site planning?

- Do we know the location of all energised cables or buried utilities?

- Is our job safety plan aligned with electrical safety standards?

- What barriers or markings are in place to prevent accidental contact with power cables?

- If you saw a cable lying across your work path, would you know whether it’s safe to move?

Published on 04/08/25

631 Views

A worker received an electric shock while moving a power cable during hose spooling. The incident highlighted site layout, barrier, and inspection issues.