-

What happened?

A vessel undertaking offshore surveys on an offshore wind project had a temporary power solution (generator set) on deck to supply office/accommodation/workshop power to the container and survey equipment.

The equipment was installed during the vessel's mobilisation of the project.

The vessel experienced a high potential incident when two 480V cables started to arc, phase to phase.

-

Why did it happen?

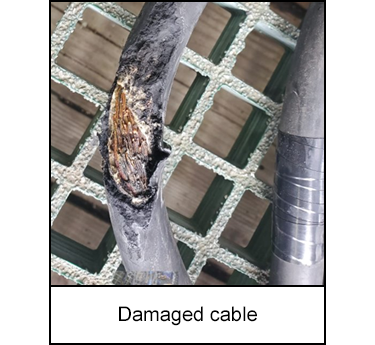

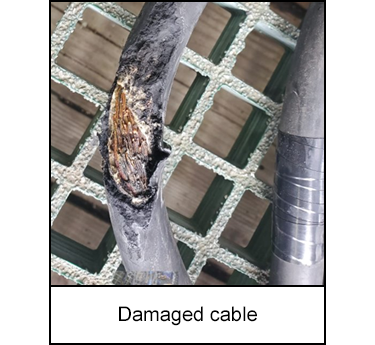

Installed cables had not been tested for insulation resistance and were in very poor condition.

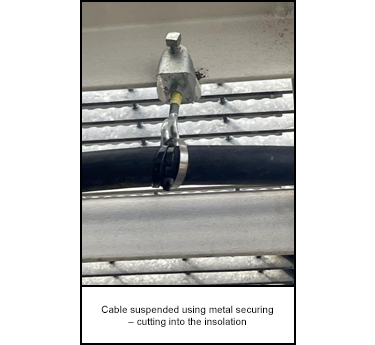

The cable insolation became damaged, allowing electricity to arc between the two cables.

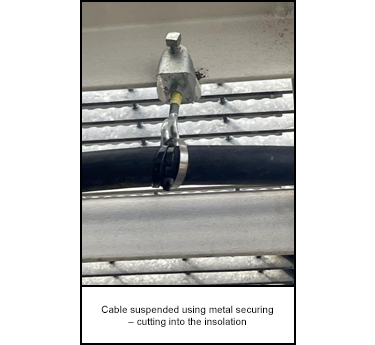

Cables were free laid on the vessel wooden deck - insulated from ground – free to move about and exposed to sea water.

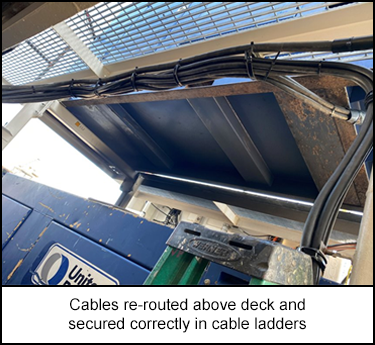

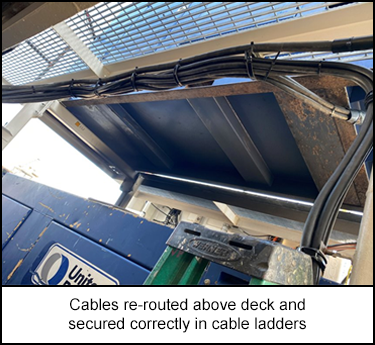

Cables were not run correctly in cable trays and ladders.

The temporary power installation was discussed during the HIRA (hazard identification and risk assessment) – control measure was that it would be a flag state approved installation and would meet local electrical safety requirements. The flag state undertook a ‘paper’ approval and did not visit the vessel.

The project suitability survey/inspection did not look at the generator installation/cable arrangement as it was before vessel mobilisation was complete.

-

What did they learn?

Update the vessel inspection and vetting procedure to include temporary power solutions to put more emphasis on the suitability of project equipment during suitability surveys (deck generators, cables, survey equipment etc).

Ensure the “HSEQ (Health, safety, environment, and quality) requirements for vendors” are reviewed by the project team to incorporate further requirements.

Confirm breaker settings are suitable for the application (i.e., continuous amps, instantaneous pick up, and ground fault pick up).

Test circuit breakers.

Test cables for insolation resistance.

Ensure contractors provide a line diagram.

Ensure arrangements are signed off by a professional electrical engineer.

-

Ask yourself or your crew

How can something like this happen here (e.g. on our site)?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

How do we know the risk controls/barriers are working?

What improvements or changes should we make to the procedures, controls/barriers, or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A vessel undertaking offshore surveys on an offshore wind project had a temporary power solution (generator set) on deck to supply office/accommodation/workshop power to the container and survey equipment.

The equipment was installed during the vessel's mobilisation of the project.

The vessel experienced a high potential incident when two 480V cables started to arc, phase to phase.

Why did it happen?

Installed cables had not been tested for insulation resistance and were in very poor condition.

The cable insolation became damaged, allowing electricity to arc between the two cables.

Cables were free laid on the vessel wooden deck - insulated from ground – free to move about and exposed to sea water.

Cables were not run correctly in cable trays and ladders.

The temporary power installation was discussed during the HIRA (hazard identification and risk assessment) – control measure was that it would be a flag state approved installation and would meet local electrical safety requirements. The flag state undertook a ‘paper’ approval and did not visit the vessel.

The project suitability survey/inspection did not look at the generator installation/cable arrangement as it was before vessel mobilisation was complete.

What did they learn?

Update the vessel inspection and vetting procedure to include temporary power solutions to put more emphasis on the suitability of project equipment during suitability surveys (deck generators, cables, survey equipment etc).

Ensure the “HSEQ (Health, safety, environment, and quality) requirements for vendors” are reviewed by the project team to incorporate further requirements.

Confirm breaker settings are suitable for the application (i.e., continuous amps, instantaneous pick up, and ground fault pick up).

Test circuit breakers.

Test cables for insolation resistance.

Ensure contractors provide a line diagram.

Ensure arrangements are signed off by a professional electrical engineer.

Ask yourself or your crew

How can something like this happen here (e.g. on our site)?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

How do we know the risk controls/barriers are working?

What improvements or changes should we make to the procedures, controls/barriers, or the way we work?

During an offshore wind project survey, a vessel's temporary generator set caused a high potential incident when two 480V cables arced phase to phase, risking significant electrical hazards.