-

What happened?

A team of installation personnel were conducting run-in-hole (RIH) completion activities and proceeded to bleed down the well and nipple down a blind flange while preparing to remove a back-pressure valve (BPV) inside the wellhead.

After bleeding down the well no pressure was observed. The team opened the master valve and inserted the BPV removal tool.

The team proceeded to unscrew the BPV with the aid of a pipe wrench. When the last thread of the BPV was reached the BPV and BPV removal tool suddenly ejected from the well followed by a cement top plug.

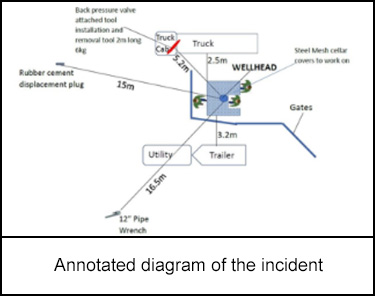

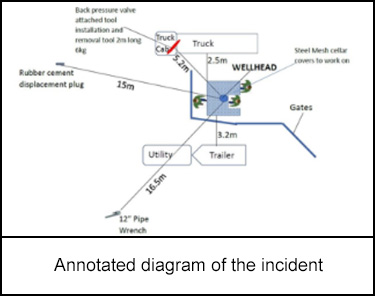

The BPV and removal tool landed about 5m (16ft) away and speared through the roof of the service truck.

The cement top plug landed 15m (49ft) from the well and the pipe wrench landed almost 17m (56ft) from the well. No personnel were injured.

-

Why did it happen?

Airlifting and flushing operations had occurred on the previous day.

This created a pressured volume of air below the plug that allowed it lift off the bottom of the well when the air pressure was released.

Personnel involved in the activity were not aware of the risk associated with plug displacement.

Failures in task planning and execution resulted in the plug moving up the well and being ejected at the surface.

-

What did they learn?

Ensure basis of design and drilling programs consider risks associated with airlifting operations occurring in close proximity to the cement top plug. This should include: further distance between perforation and total depth (TD); the amount of cement to be placed above cement the top plug; and the process for when cement returns are identified during airlifting operations. BPV removal was not included as part of the drilling program for RIH completions.

Ensure adherence to the drilling program. Although the drilling program stipulated the use of a two-plug system for the cement program, only a top plug was used. Deviations must be appropriately assessed and authorised.

Implement control of work processes. The permit to work and toolbox meetings did not cover the specific task. A job hazard analysis (JHA) / standard operating procedure (SOP) for BPV removal was not available.

Conduct formal training and competence assessment. Personnel engaged in the activity were experienced, but did not have formal training or competence assessment.

-

Ask yourself or your crew

Does your well basis of design and drilling program consider risks associated with airlifting operations occurring in close proximity to the top plug?

Are you following your drilling program? How do you know?

Are you involved in BPV removal? Are you formally trained and assessed as competent to complete the task? Are you aware of the risk associated with plug displacement after airlifting and flushing? Do you conduct this task under a permit to work? Do you have JHAs/ SOPs covering this task? Do you follow them? Do you discuss these risks in your toolbox talks?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A team of installation personnel were conducting run-in-hole (RIH) completion activities and proceeded to bleed down the well and nipple down a blind flange while preparing to remove a back-pressure valve (BPV) inside the wellhead.

After bleeding down the well no pressure was observed. The team opened the master valve and inserted the BPV removal tool.

The team proceeded to unscrew the BPV with the aid of a pipe wrench. When the last thread of the BPV was reached the BPV and BPV removal tool suddenly ejected from the well followed by a cement top plug.

The BPV and removal tool landed about 5m (16ft) away and speared through the roof of the service truck.

The cement top plug landed 15m (49ft) from the well and the pipe wrench landed almost 17m (56ft) from the well. No personnel were injured.

Why did it happen?

Airlifting and flushing operations had occurred on the previous day.

This created a pressured volume of air below the plug that allowed it lift off the bottom of the well when the air pressure was released.

Personnel involved in the activity were not aware of the risk associated with plug displacement.

Failures in task planning and execution resulted in the plug moving up the well and being ejected at the surface.

What did they learn?

Ensure basis of design and drilling programs consider risks associated with airlifting operations occurring in close proximity to the cement top plug. This should include: further distance between perforation and total depth (TD); the amount of cement to be placed above cement the top plug; and the process for when cement returns are identified during airlifting operations. BPV removal was not included as part of the drilling program for RIH completions.

Ensure adherence to the drilling program. Although the drilling program stipulated the use of a two-plug system for the cement program, only a top plug was used. Deviations must be appropriately assessed and authorised.

Implement control of work processes. The permit to work and toolbox meetings did not cover the specific task. A job hazard analysis (JHA) / standard operating procedure (SOP) for BPV removal was not available.

Conduct formal training and competence assessment. Personnel engaged in the activity were experienced, but did not have formal training or competence assessment.

Ask yourself or your crew

Does your well basis of design and drilling program consider risks associated with airlifting operations occurring in close proximity to the top plug?

Are you following your drilling program? How do you know?

Are you involved in BPV removal? Are you formally trained and assessed as competent to complete the task? Are you aware of the risk associated with plug displacement after airlifting and flushing? Do you conduct this task under a permit to work? Do you have JHAs/ SOPs covering this task? Do you follow them? Do you discuss these risks in your toolbox talks?

A back-pressure valve and cement plug were ejected from a well during completion activities, damaging a service truck but causing no injuries.

Original material courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/loss-of-well-control-learning-event-bulletin