-

What happened?

The rig contractor was in the process of rigging down from a well, and the logistics contractor was removing the V-door from the substructure.

While lifting the load, the crane reversed, causing it to bind. This dislodged one of the D-Rings, and the V-door fell about 3 metres (10 feet) onto the drill line and managed pressure drilling line below.

Fortunately, no injuries were reported as all personnel were clear of the area at the time of the event.

-

Why did it happen?

There was inadequate supervision, failure to follow proper lifting practices, and a lack of hazard identification and management.

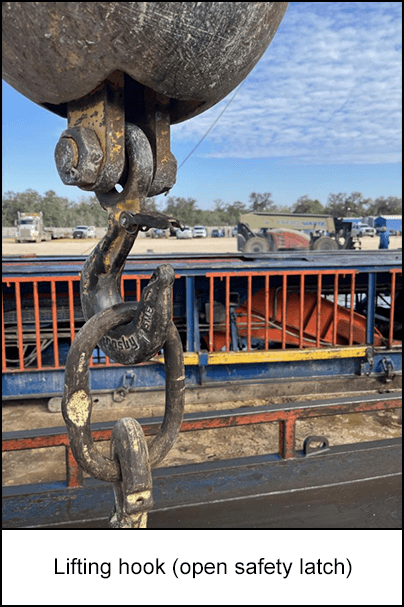

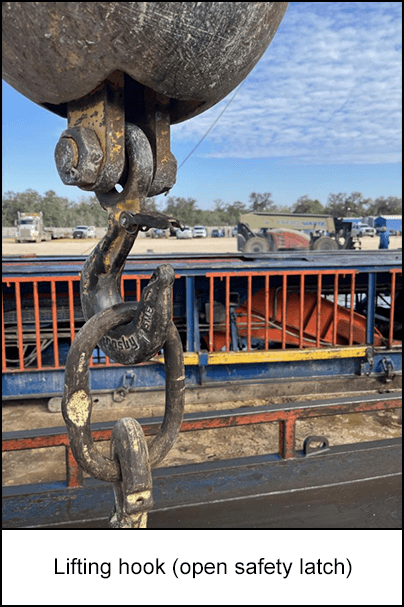

- no pre-lift crane inspection or ensure proper rigging equipment;

- onsite personnel did not adhere to established lifting practices.

-

What did they learn?

Implement daily crane inspections.

Reiterate existing procedures for crane lifting operations to ensure personnel understand and apply them.

Where appropriate, consider replacing the lifting hook latch and introduce additional four-leg chain slings to prevent improper lifting angles.

Conduct toolbox talks to emphasize the importance of following established procedures and safe work practices.

Train / retrain to enhance hazard identification and risk mitigation skills.

-

Ask yourself or your crew

How can something like this happen here (e.g. on our site)?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

How do we know the risk controls/barriers are working?

What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

The rig contractor was in the process of rigging down from a well, and the logistics contractor was removing the V-door from the substructure.

While lifting the load, the crane reversed, causing it to bind. This dislodged one of the D-Rings, and the V-door fell about 3 metres (10 feet) onto the drill line and managed pressure drilling line below.

Fortunately, no injuries were reported as all personnel were clear of the area at the time of the event.

Why did it happen?

There was inadequate supervision, failure to follow proper lifting practices, and a lack of hazard identification and management.

- no pre-lift crane inspection or ensure proper rigging equipment;

- onsite personnel did not adhere to established lifting practices.

What did they learn?

Implement daily crane inspections.

Reiterate existing procedures for crane lifting operations to ensure personnel understand and apply them.

Where appropriate, consider replacing the lifting hook latch and introduce additional four-leg chain slings to prevent improper lifting angles.

Conduct toolbox talks to emphasize the importance of following established procedures and safe work practices.

Train / retrain to enhance hazard identification and risk mitigation skills.

Ask yourself or your crew

How can something like this happen here (e.g. on our site)?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

How do we know the risk controls/barriers are working?

What improvements or changes should we make to the procedures, controls/barriers or the way we work?

The rig contractor was in the process of rigging down from a well, and the logistics contractor was removing the V-door from the substructure. While lifting the load, the crane reversed, causing it to bind. This dislodged one of the D-Rings, and the V-door fell about 3 metres (10 feet) onto the drill line and managed pressure drilling line below. Fortunately, no injuries were reported as all personnel were clear of the area at the time of the event.