-

What happened?

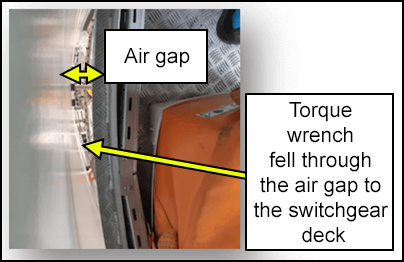

While working on the top deck of a transition piece (TP), a technician placed a torque wrench on top of a tool bag situated close to the edge of the deck.

He hit the bag by mistake during work completion, causing the wrench to fall into the air gap between the deck and TP wall (see image).

The item fell from the top deck to the switchgear level, where technicians were working at the time. Fortunately, no one was injured.

The impact force of the torque wrench could have caused a personal injury.

-

Why did it happen?

The torque wrench was not properly secured and stored during the task.

The air gap between the deck and transition piece wall was used for ventilation and was big enough to allow items to fall through.

The air gap was not considered to be a potential dropped object hazard, therefore the work instructions did not include mitigation measures for the prevention of dropped objects through air gaps.

-

What did they learn?

When working at height, always ensure that tools are placed properly in the tool bags when not in use (i.e. before, during and after completing the work).

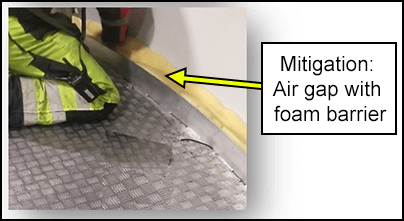

Conduct a risk assessment before starting the job to identify any potential dropped objects in the workspace. If needed, stop the work, and assess what mitigation measures can be put in place. In this case, the air gap was filled with foam barrier as a temporary solution (see image).

At design stage, consider design optimisation to account for potential dropped objects through air gaps.

-

Ask yourself or your crew

Observe your work area. What potential dropped objects can you spot?

How do you report a potential dropped object, and what needs to happen before work can be resumed in that area?

Are there any teams working on the levels below you? What can you do to minimise the risk of objects falling to their locations?

What measures do we have in place for dropped objects prevention? What more can we do to make our operations safer?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

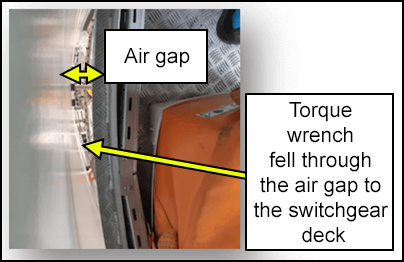

While working on the top deck of a transition piece (TP), a technician placed a torque wrench on top of a tool bag situated close to the edge of the deck.

He hit the bag by mistake during work completion, causing the wrench to fall into the air gap between the deck and TP wall (see image).

The item fell from the top deck to the switchgear level, where technicians were working at the time. Fortunately, no one was injured.

The impact force of the torque wrench could have caused a personal injury.

Why did it happen?

The torque wrench was not properly secured and stored during the task.

The air gap between the deck and transition piece wall was used for ventilation and was big enough to allow items to fall through.

The air gap was not considered to be a potential dropped object hazard, therefore the work instructions did not include mitigation measures for the prevention of dropped objects through air gaps.

What did they learn?

When working at height, always ensure that tools are placed properly in the tool bags when not in use (i.e. before, during and after completing the work).

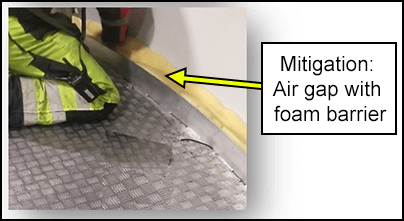

Conduct a risk assessment before starting the job to identify any potential dropped objects in the workspace. If needed, stop the work, and assess what mitigation measures can be put in place. In this case, the air gap was filled with foam barrier as a temporary solution (see image).

At design stage, consider design optimisation to account for potential dropped objects through air gaps.

Ask yourself or your crew

Observe your work area. What potential dropped objects can you spot?

How do you report a potential dropped object, and what needs to happen before work can be resumed in that area?

Are there any teams working on the levels below you? What can you do to minimise the risk of objects falling to their locations?

What measures do we have in place for dropped objects prevention? What more can we do to make our operations safer?

While working on the top deck of a transition piece, a technician placed a torque wrench on top of a tool bag situated close to the edge of the deck. He hit the bag by mistake, causing the wrench to fall through an air gap all the way down to the switchgear deck. Fortunately, no one was injured. Upon calculations, it was concluded that the impact force of the torque wrench could have caused a personal injury.