-

What happened?

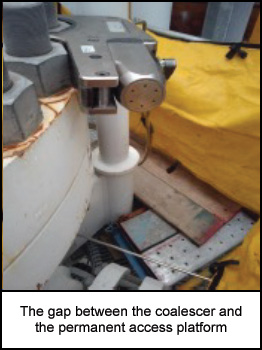

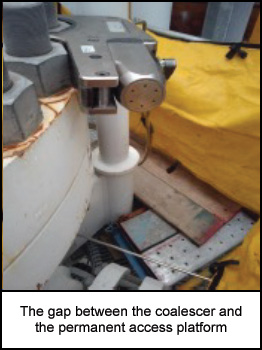

Two workers were working approximately 5 metres (16 feet) above the ground on a permanent access platform, removing the lid on a tri-ethylene glycol (TEG) discharge coalescer as part of a scope of works to replace the filter cartridges.

While slackening the studs, using a hytorq cassette and a flogging spanner as a backing spanner, the flogging spanner was dropped and fell through the gap between the access platform and the coalescer.

The falling spanner struck the upper isolation valve, causing damage to the flange, and then impacted a nearby line to the open drain system before landing on the ground.

The spanner fell within the established exclusion zone.

-

Why did it happen?

There was a gap between the permanent access platform and the coalescer which was large enough for the spanner to fall through.

The gap was identified, but not perceived to be a hazard because the technician believed that the gap was too small for the spanner to fall through it.

Further, the spanner could only fall through the gap if it deflected as it fell.

The spanner dropped out of the technician’s hand and was deflected off their knee through the gap.

-

What did they learn?

Securely cover all potential gaps to prevent a potential dropped object. Scaffolding plans should include:

- details for dropped objects protection in the functional description

- at the post-scaffolding inspection, processes to verify that dropped objects protection is sufficient.

Use tool lanyards, unless the use of a lanyard introduces additional hazard. Tool lanyards may be attached to a person (if less than 2kg/4lbs) or alternatively can be attached to a safe and secure anchor point.

Ensure that exclusion zones are adequately sized, particularly where there is a risk of deflection.

Evaluate opportunities to substitute tooling that may require less force or manual effort in its application.

-

Ask yourself or your crew

What do you do at your worksite to prevent non-secured tools and equipment, and small pieces (e.g. nuts and bolts), from slipping through openings such as walkway gratings and access platform penetrations?

Do you perform regular inspections of equipment and work areas at your work site to identify dropped object hazard areas?

When a potential dropped object is identified, do you and your work mates discuss the “what if” question? (e.g. What if that falls - could it hit people or plant? What is the worst outcome if it did?)

When an actual or potential dropped object is identified, do you report it to your supervisor?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Two workers were working approximately 5 metres (16 feet) above the ground on a permanent access platform, removing the lid on a tri-ethylene glycol (TEG) discharge coalescer as part of a scope of works to replace the filter cartridges.

While slackening the studs, using a hytorq cassette and a flogging spanner as a backing spanner, the flogging spanner was dropped and fell through the gap between the access platform and the coalescer.

The falling spanner struck the upper isolation valve, causing damage to the flange, and then impacted a nearby line to the open drain system before landing on the ground.

The spanner fell within the established exclusion zone.

Why did it happen?

There was a gap between the permanent access platform and the coalescer which was large enough for the spanner to fall through.

The gap was identified, but not perceived to be a hazard because the technician believed that the gap was too small for the spanner to fall through it.

Further, the spanner could only fall through the gap if it deflected as it fell.

The spanner dropped out of the technician’s hand and was deflected off their knee through the gap.

What did they learn?

Securely cover all potential gaps to prevent a potential dropped object. Scaffolding plans should include:

- details for dropped objects protection in the functional description

- at the post-scaffolding inspection, processes to verify that dropped objects protection is sufficient.

Use tool lanyards, unless the use of a lanyard introduces additional hazard. Tool lanyards may be attached to a person (if less than 2kg/4lbs) or alternatively can be attached to a safe and secure anchor point.

Ensure that exclusion zones are adequately sized, particularly where there is a risk of deflection.

Evaluate opportunities to substitute tooling that may require less force or manual effort in its application.

Ask yourself or your crew

What do you do at your worksite to prevent non-secured tools and equipment, and small pieces (e.g. nuts and bolts), from slipping through openings such as walkway gratings and access platform penetrations?

Do you perform regular inspections of equipment and work areas at your work site to identify dropped object hazard areas?

When a potential dropped object is identified, do you and your work mates discuss the “what if” question? (e.g. What if that falls - could it hit people or plant? What is the worst outcome if it did?)

When an actual or potential dropped object is identified, do you report it to your supervisor?

Two workers on a platform dropped a flogging spanner, which damaged an upper isolation valve and a nearby line before landing within the exclusion zone.

Original material courtesy of Safer Together (Australia)

To access the PDF and PowerPoint versions, please visit https://www.safertogether.com.au/resources/sharing-library/working-at-height-person-in-line-of-fire-leb-toolbox