-

What happened?

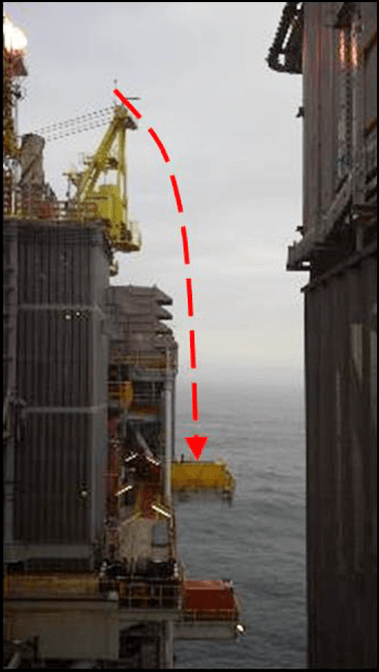

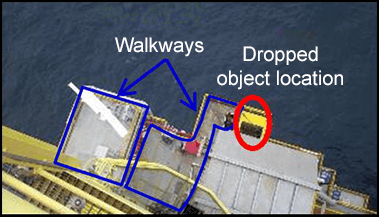

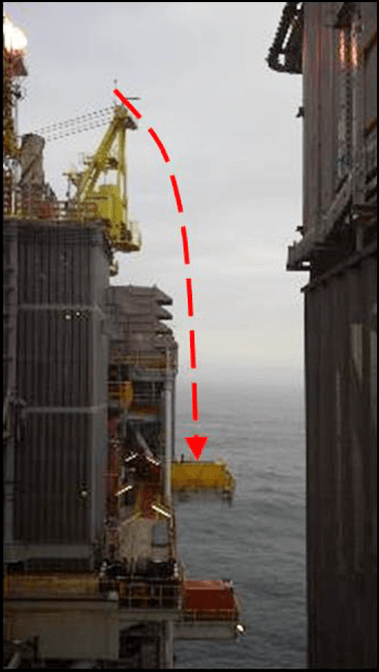

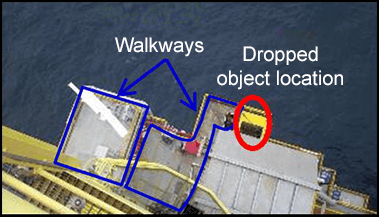

A 2 kg (5lb) crane windsock fell approximately 30 metres (98.5 feet), landing in an open-top container within the laydown area. Fortunately, no one was present in the vicinity at the time of the incident.

The sequence of events unfolded as follows:

- The windsock was properly positioned at the commencement of the nightshift.

- At around 11 pm, personnel in the area sought access to a walk-in, open-top container and discovered the windsock lying on the floor.

- It is suspected that one of the two bolts responsible for securing the windsock had come loose.

- Subsequently, the second bracket bolt assembly failed due to fatigue, resulting in the object being dropped.

-

Why did it happen?

The windsock fastening mechanism was susceptible to loosening and did not have secondary retention.

The condition of the bolt was not visible from vantage point for daily crane pre-use visual inspections. This required the involvement of a rope access technician for a thorough examination.

-

What did they learn?

Verify that the crane windsock framework has a secondary retention.

Include windsock framework (including bolts, brackets, and shackles) and supporting structure inspection in the preventative maintenance program.

Include windsock and frame in the potential dropped objects observation program.

-

Ask yourself or your crew

How can something like this happen here?

What additional safety measures can we implement to ensure windsocks and other objects at height remain securely fastened?

What does our dropped objects observation program include? What else should we add?

What safety measures and procedures do we have in place to prevent dropped objects on our site? How can we improve?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A 2 kg (5lb) crane windsock fell approximately 30 metres (98.5 feet), landing in an open-top container within the laydown area. Fortunately, no one was present in the vicinity at the time of the incident.

The sequence of events unfolded as follows:

- The windsock was properly positioned at the commencement of the nightshift.

- At around 11 pm, personnel in the area sought access to a walk-in, open-top container and discovered the windsock lying on the floor.

- It is suspected that one of the two bolts responsible for securing the windsock had come loose.

- Subsequently, the second bracket bolt assembly failed due to fatigue, resulting in the object being dropped.

Why did it happen?

The windsock fastening mechanism was susceptible to loosening and did not have secondary retention.

The condition of the bolt was not visible from vantage point for daily crane pre-use visual inspections. This required the involvement of a rope access technician for a thorough examination.

What did they learn?

Verify that the crane windsock framework has a secondary retention.

Include windsock framework (including bolts, brackets, and shackles) and supporting structure inspection in the preventative maintenance program.

Include windsock and frame in the potential dropped objects observation program.

Ask yourself or your crew

How can something like this happen here?

What additional safety measures can we implement to ensure windsocks and other objects at height remain securely fastened?

What does our dropped objects observation program include? What else should we add?

What safety measures and procedures do we have in place to prevent dropped objects on our site? How can we improve?

A 2 kg (5lb) crane windsock fell approximately 30 metres (98.5 feet), landing in an open-top container within the laydown area. Fortunately, no one was present in the vicinity at the time of the incident.