-

What happened?

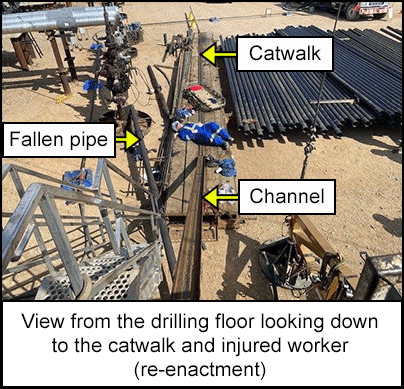

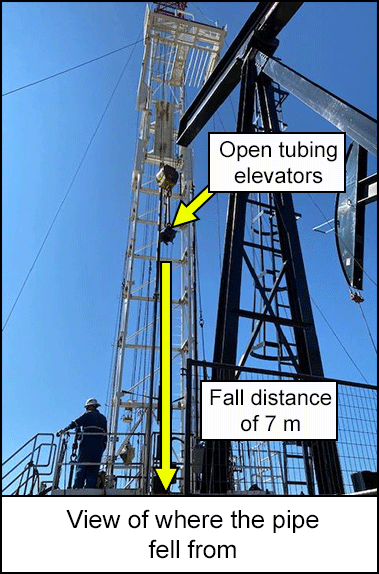

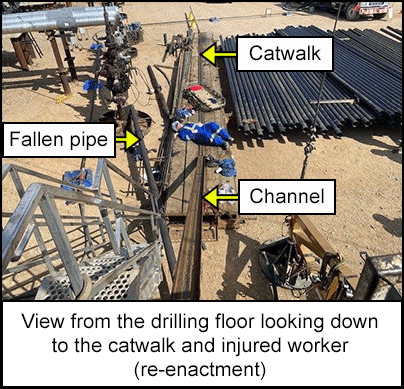

A service rig crew was lowering casing pipe (tail joint) into the channel slide when it snagged on the edge of the channel.

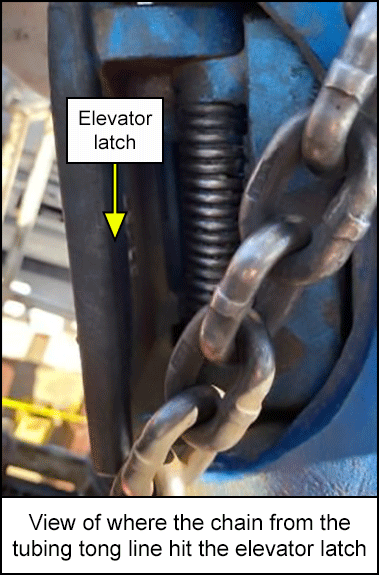

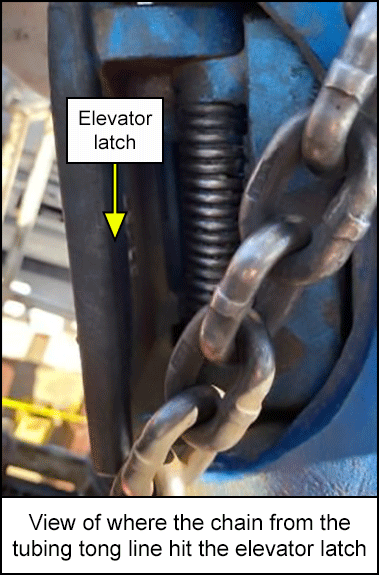

This caused the travelling block assembly and tubing elevators to swing past the tubing tong line. When the snag released, the assembly began to swing back and, as the elevators passed the tubing tong line, a link on the chain hit the elevator latch.

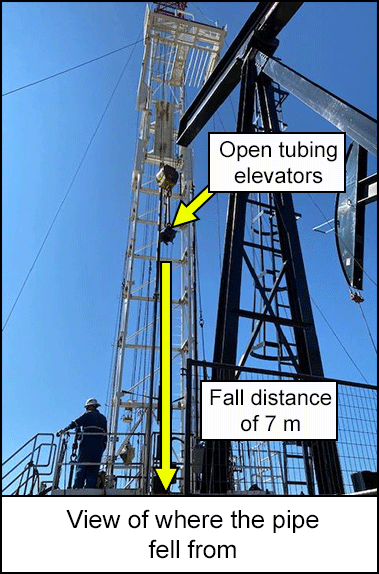

The elevators opened and the pipe was released, striking a worker in the face on the catwalk below. The worker was seriously injured.

-

Why did it happen?

- The elevators are rated for working with casing. To remain stable, however, the casing must not move more than 15 degrees horizontally. When the snag occurred, that angle was exceeded.

- A link on the winch chain hit the latch, opening the elevators.

-

What did they learn?

Use side entry elevators for picking up and lowering casing to the ground.

Use a pullback line when lowering bottom hole assembly (BHA) to the ground.

When suspending equipment like tubing tongs, remove winch chains.

Establish a continuous improvement team to develop a solution so workers are not in the line of fire. NOTE: The injured worker was positioned as per company policy, practices and procedures.

-

Ask yourself or your crew

How can we prevent something like this from happening here?

What are other risks are associated with forklift operations? How can you mitigate those risks at your work site?

What safety recommendations should be included in the operational instructions?

How can we, as a company, implement a practical training plan that focuses on the job position, and make sure pedestrians are safer from forklifts in the future?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A service rig crew was lowering casing pipe (tail joint) into the channel slide when it snagged on the edge of the channel.

This caused the travelling block assembly and tubing elevators to swing past the tubing tong line. When the snag released, the assembly began to swing back and, as the elevators passed the tubing tong line, a link on the chain hit the elevator latch.

The elevators opened and the pipe was released, striking a worker in the face on the catwalk below. The worker was seriously injured.

Why did it happen?

- The elevators are rated for working with casing. To remain stable, however, the casing must not move more than 15 degrees horizontally. When the snag occurred, that angle was exceeded.

- A link on the winch chain hit the latch, opening the elevators.

What did they learn?

Use side entry elevators for picking up and lowering casing to the ground.

Use a pullback line when lowering bottom hole assembly (BHA) to the ground.

When suspending equipment like tubing tongs, remove winch chains.

Establish a continuous improvement team to develop a solution so workers are not in the line of fire. NOTE: The injured worker was positioned as per company policy, practices and procedures.

Ask yourself or your crew

How can we prevent something like this from happening here?

What are other risks are associated with forklift operations? How can you mitigate those risks at your work site?

What safety recommendations should be included in the operational instructions?

How can we, as a company, implement a practical training plan that focuses on the job position, and make sure pedestrians are safer from forklifts in the future?

A service rig crew was lowering casing pipe (tail joint) into the channel slide when it snagged on the edge of the channel causing the travelling block assembly and tubing elevators to swing past the tubing tong line. When the snag released, the assembly began to swing back and a link on the chain hit the elevator latch. The elevators opened and the pipe was released, striking and seriously injuring a worker on the catwalk below.

Original material courtesy of Energy Safety Canada

Other resources:

Dropped Objects Best Practice

Dropped Objects Microlearning Video

Energy Safety Canada partnered with DROPS (DropsOnline.org) to establish a Canadian chapter. To become a member, review the Terms of Reference on the Canadian Chapter DROPS website and send an email to express your interest.

Are You in the “Line of Fire?” Program