-

What happened?

The driver of a tank truck was unloading fluid at a production facility.

The driver was found unresponsive inside the pump box of their truck with their left arm sleeve entangled in the pump shaft.

After an hour and 30 minutes of resuscitation efforts by workers and emergency response personnel, the worker was declared deceased from mechanical asphyxiation.

-

Why did it happen?

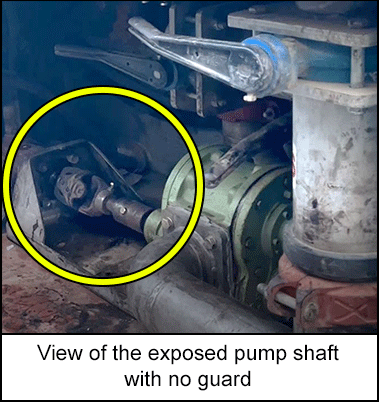

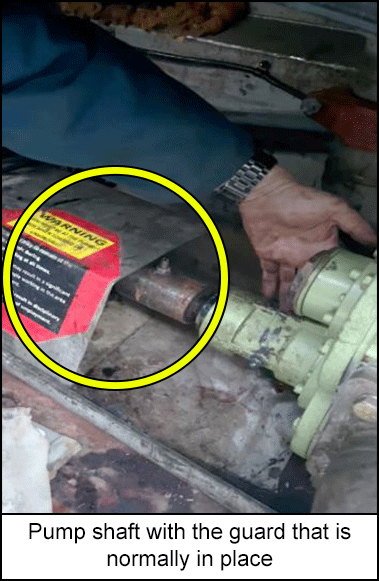

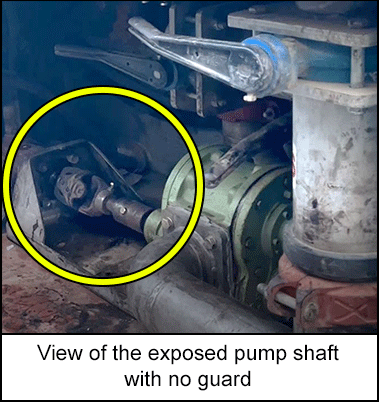

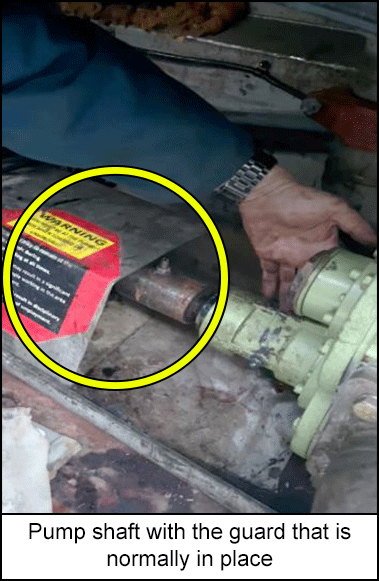

- The factory guard that is normally over the pump shaft had been removed, exposing several catch hazards. The guard was in place the previous day.

- Post-incident testing of the equipment found no abnormal operating conditions that would have required the guard to be removed.

- Evidence indicated that the worker was overtop of the exposed catch hazards, greasing the rear grease point on the pump while the shaft was rotating at 700 revolutions per minute (RPMs).

-

What did they learn?

Engineering controls:

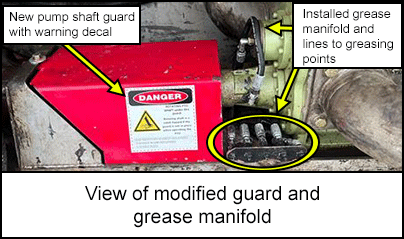

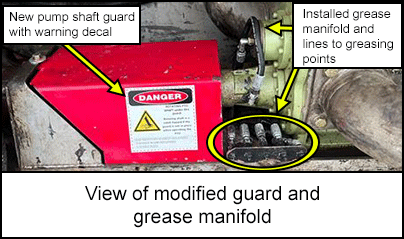

- Installed a grease manifold so drivers do not need to lean over the pump when conducting greasing activities.

- Changed guards on all trucks to a type that fully covers the shaft’s catch hazards and is more difficult to remove.

Administrative controls:

- Conducted a policy review with company personnel to review and reinforce that all guards must be in place during operation and should only be removed with authorization and proper lock-out/tag-out (LOTO).

- Added warning decals to the new guards.

- Updated the greasing procedure and in-service documentation.

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

If you want to add this app to home screen tap and then ‘Add to Home Screen’.

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

The driver of a tank truck was unloading fluid at a production facility.

The driver was found unresponsive inside the pump box of their truck with their left arm sleeve entangled in the pump shaft.

After an hour and 30 minutes of resuscitation efforts by workers and emergency response personnel, the worker was declared deceased from mechanical asphyxiation.

Why did it happen?

- The factory guard that is normally over the pump shaft had been removed, exposing several catch hazards. The guard was in place the previous day.

- Post-incident testing of the equipment found no abnormal operating conditions that would have required the guard to be removed.

- Evidence indicated that the worker was overtop of the exposed catch hazards, greasing the rear grease point on the pump while the shaft was rotating at 700 revolutions per minute (RPMs).

What did they learn?

Engineering controls:

- Installed a grease manifold so drivers do not need to lean over the pump when conducting greasing activities.

- Changed guards on all trucks to a type that fully covers the shaft’s catch hazards and is more difficult to remove.

Administrative controls:

- Conducted a policy review with company personnel to review and reinforce that all guards must be in place during operation and should only be removed with authorization and proper lock-out/tag-out (LOTO).

- Added warning decals to the new guards.

- Updated the greasing procedure and in-service documentation.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Published on 07/04/23

1834 Views

The driver of a tank truck was unloading fluid at a production facility. The driver was found unresponsive inside the pump box of their truck with their left arm sleeve entangled in the pump shaft. After an hour and 30 minutes of resuscitation efforts by workers and emergency response personnel, the worker was declared deceased from mechanical asphyxiation.

Original material courtesy of Energy Safety Canada

Other resources:

Energy isolation - video

Bypassing safety controls - video

Life Saving Rules

Safety Critical Procedures Safety Bulletin