-

What happened?

An employer experienced an equipment failure of a skid-mounted solids centrifuge.

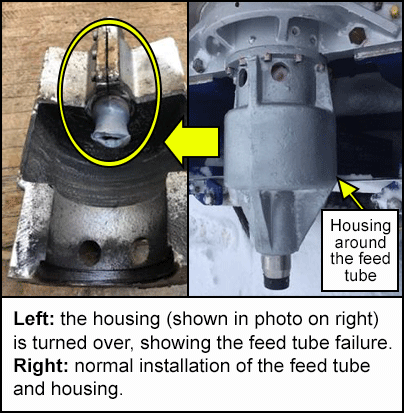

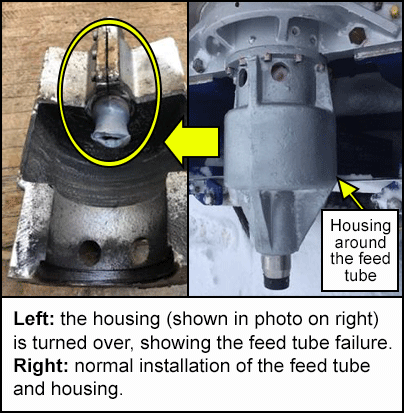

The feed tube detached from the centrifuge because of vibrations from mounting bolts that had backed out. The feed tube detached, causing the steel housing around it to be ejected.

No personnel were in the area where the housing landed.

-

Why did it happen?

Vibrations from the loose bolts caused the feed tube to shear off from the centrifuge

body, catapulting the housing.Contributing factors:

- The feed tube was projected approximately 18 meters (60 feet) from the unit onto a

roof panel of the neighbouring mud tank, landing on the mats below.

- The feed tube was projected approximately 18 meters (60 feet) from the unit onto a

-

What did they learn?

Employers, including rental equipment companies, must ensure adequate QA/QC procedure to confirm the proper type and securement of bolts and other critical steps for high-RPM rotating equipment.

-

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Add to homescreen

If you want to add this app to home screen tap and then ‘Add to Home Screen’.

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

An employer experienced an equipment failure of a skid-mounted solids centrifuge.

The feed tube detached from the centrifuge because of vibrations from mounting bolts that had backed out. The feed tube detached, causing the steel housing around it to be ejected.

No personnel were in the area where the housing landed.

Why did it happen?

Vibrations from the loose bolts caused the feed tube to shear off from the centrifuge

body, catapulting the housing.

Contributing factors:

- The feed tube was projected approximately 18 meters (60 feet) from the unit onto a

roof panel of the neighbouring mud tank, landing on the mats below.

What did they learn?

Employers, including rental equipment companies, must ensure adequate QA/QC procedure to confirm the proper type and securement of bolts and other critical steps for high-RPM rotating equipment.

Ask yourself or your crew

- How can something like this happen here (e.g. on our site)?

- What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

- How do we know the risk controls/barriers are working?

- What improvements or changes should we make to the procedures, controls/barriers or the way we work?

Published on 26/06/23

1191 Views

An incident occurred involving a skid-mounted solids centrifuge, where the feed tube detached due to vibrations from mounting bolts that had backed out. As a result, the steel housing around it to be ejected. Fortunately, no personnel were injured as no one was in the area.